Preparation method of dried Larimichthys crocea fresh-increasing peptide powder

A technology of large yellow croaker and peptide powder, applied in the preparation method of peptide, chemical equipment and method, peptide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

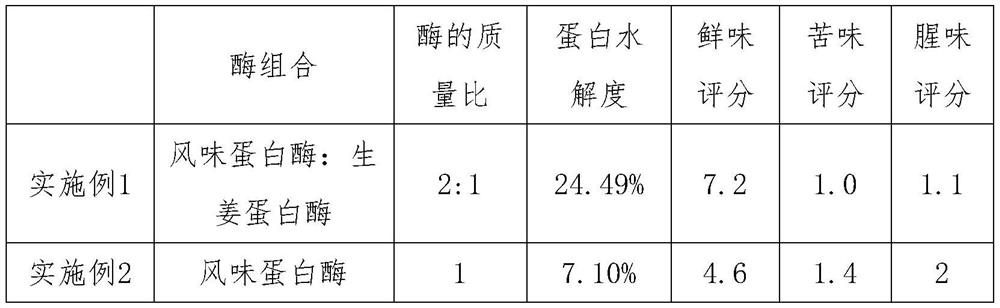

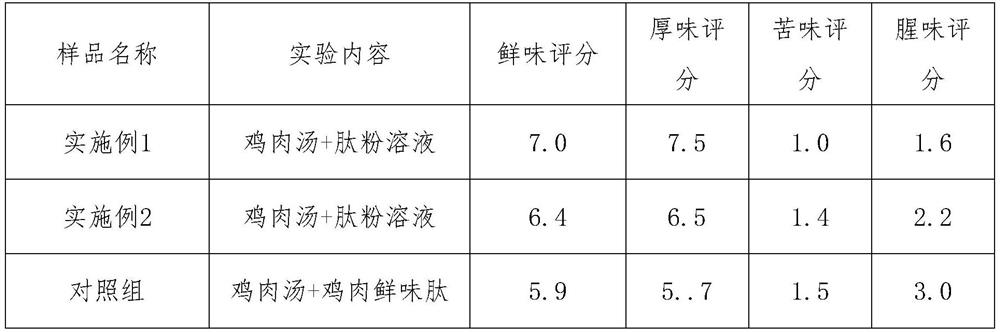

Embodiment 1

[0022] The preparation method of embodiment 1 large yellow croaker dried umami taste peptide powder, comprises the following steps:

[0023] 1. After thawing the frozen dried large yellow croaker in running water for 1.5 hours, take the carcass muscle of the fish, add distilled water twice the mass of the fish, mince, and homogenize.

[0024] 2. Add 0.6% protease to the mixed fish paste. The amount of ginger protease accounts for 50% of the total enzyme amount. Enzymolysis takes 2.5 hours. , and then add ginger protease whose quality is 50% of flavor protease, and enzymolyze it for 2.5h, and enzymolyze it in a water bath at 50°C for 2.5h; the added protease is selected from flavor protease and ginger protease, and the order of enzyme addition is flavor protease Protease, ginger protease, the initial pH value of the enzymatic hydrolysis system is 5.5, the enzymatic hydrolysis is finished in a 95°C water bath for 15 minutes, the enzymatic hydrolyzate is passed through an 80-mesh...

Embodiment 2

[0028] The preparation method of embodiment 2 large yellow croaker dried umami taste peptide powder, comprises the following steps:

[0029] 1. After thawing frozen dried large yellow croaker in running water for 2 hours, take the carcass muscle of the fish, add distilled water twice the mass of the fish, mince, and homogenize.

[0030] 2. Add 0.6% protease to the mixed fish paste, enzymatic hydrolysis for 3 hours, the enzymatic hydrolysis temperature is 60°C, and the enzymatic hydrolysis is completed in a 100°C water bath for 10 minutes, and the enzymatic hydrolyzate is passed through 100 mesh Sieve, and then centrifuge the filtrate at 10,000 r / min at 4°C for 15 min, and collect the supernatant.

[0031] 3. After the supernatant was filtered through a 5000Da ultrafiltration membrane, the components with a MW<5000Da were separated through a Sephadex G15 column with distilled water as the eluent, and the elution rate was 1mL / min.

[0032]4. The elution peaks were separated by ...

Embodiment 3

[0034] The preparation method of embodiment 3 large yellow croaker dried umami taste peptide powder, comprises the following steps:

[0035] 1. After thawing frozen dried large yellow croaker in running water for 4 hours, take the carcass muscle of the fish, add distilled water 4 times the mass of the fish, mince, and homogenize.

[0036] 2. Add 1.8% protease to the mixed fish paste, wherein the amount of ginger protease accounts for 25% of the total enzyme amount. Enzymolysis takes 2 hours at a temperature of 60°C. The added protease is selected from flavor protease and ginger There are two types of proteases, the order of adding enzymes is flavor protease and ginger protease; the initial pH value of the enzymolysis system is 7.5, and the enzyme is extinguished in a water bath at 100°C for 10 minutes after the enzymolysis is completed. After centrifugation at 10000r / min, 6°C for 15min, the supernatant was collected.

[0037] 3. After the supernatant was filtered through a 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com