Preparation method of metal sulfide porous single crystal

A metal sulfide and sulfide technology, which is applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems that have not been seen in the literature, and achieve the effect of simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Porous single crystal NiS 2 As a case, the implementation of the scheme is introduced in detail: take 2g of SiO 2 Nanosphere close-packed template, added to NiCl with a concentration of 0.01mmol / L 2 ·6H 2 In O aqueous solution, stir at room temperature for 12 hours; pour off the liquid after standing for 3 minutes, rinse the template with deionized water for 3 to 5 times, and dry the template at 60° C. to fully adsorb Ni substances on the template. Take the dried template and heat it in a tube furnace at 600°C for 60 minutes, use nitrogen or argon as the carrier gas, the carrier gas flow rate is 50 sccm, place 1 g of thiourea in the upstream of the carrier gas flow, and the carrier gas will drive the thiourea to decompose by heat The gas passes through the template to vulcanize the Ni substance adsorbed on the template, so that the template becomes a uniform gray pre-seeded template, indicating that the pre-seeded crystal is completed.

[0035] Among them, SiO 2 The...

Embodiment 1

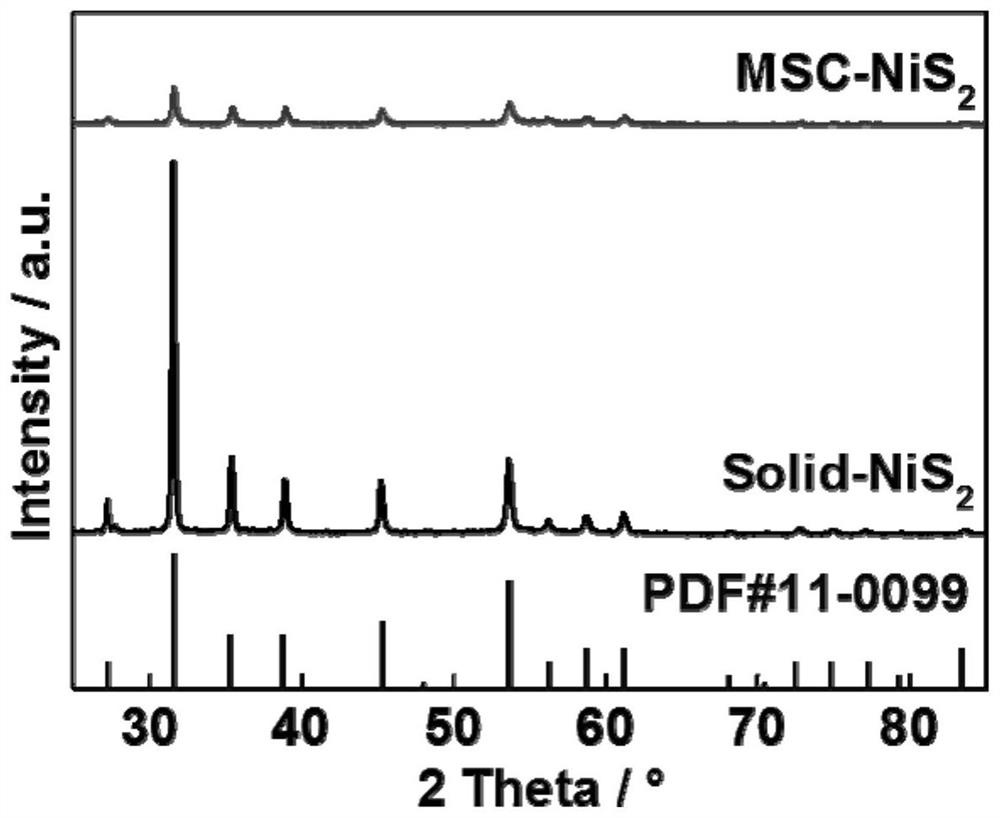

[0039] Porous single crystal NiS prepared by adding silica nanospheres (50nm) close-packed templates pre-seeded by impregnation method 2 (MSC-NiS 2 ) and non-porous single crystal NiS prepared without prefabricated templates 2 (Solid-NiS 2 ) As a comparison, the phases of samples prepared according to this method were studied.

[0040] X-ray testing equipment and conditions: Rigaku D / max 2500, Cu Ka rays. Such as figure 1 As shown, it is porous single crystal NiS 2 with nonporous single crystal NiS 2 X-ray diffraction pattern of . It can be seen from the figure that the added template has no effect on the phase of the sample, and it is still a blazonite structure with a single phase; at the same time, compared with the non-porous single-crystal sample, the diffraction of the porous single-crystal sample The peak broadens obviously, which can be understood as the scattering effect of the porous structure on X-rays.

Embodiment 2

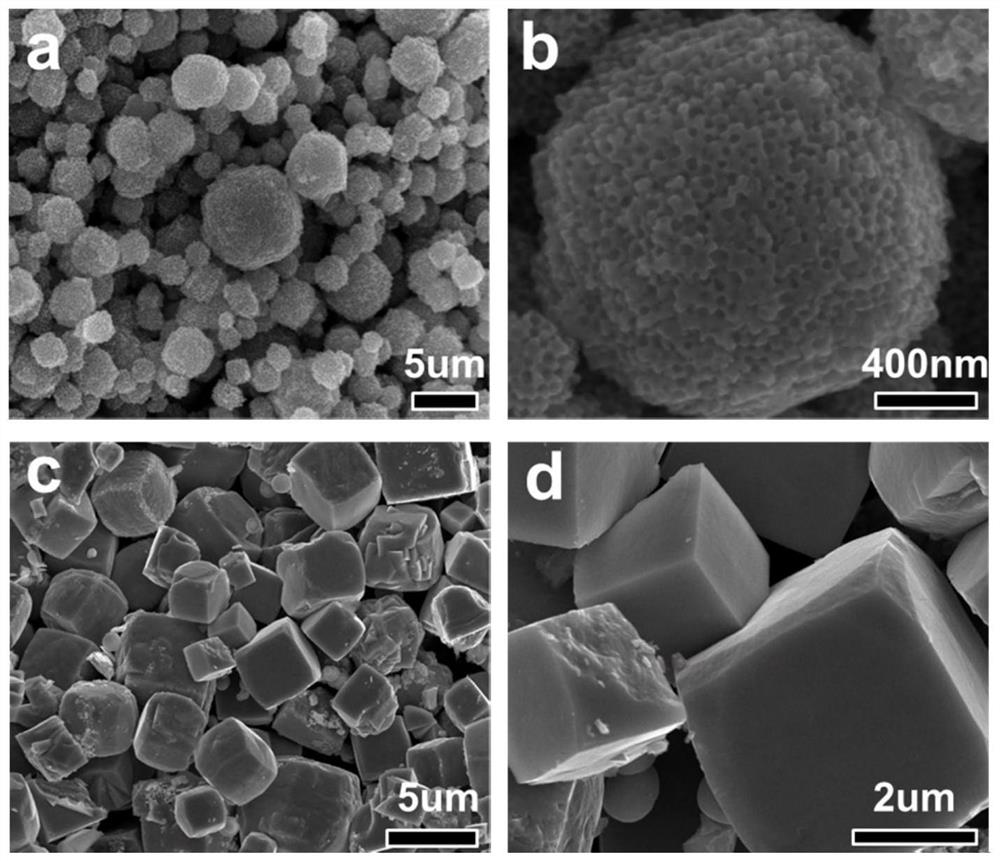

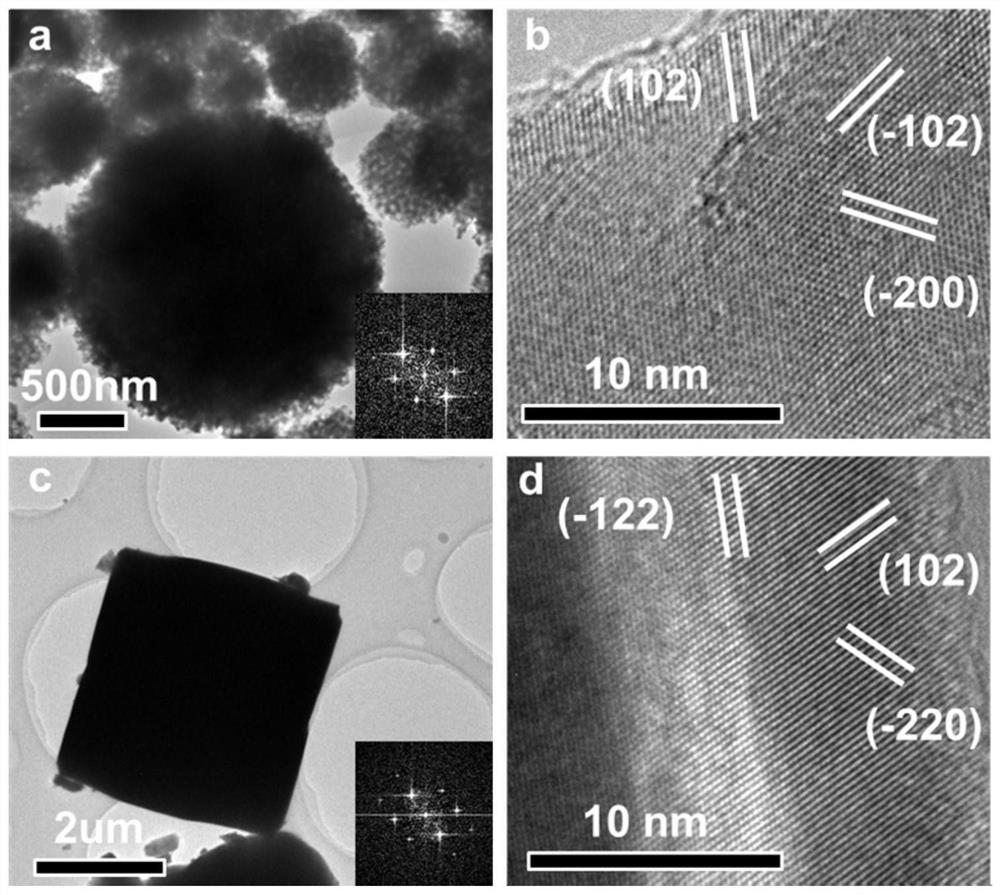

[0042] Porous single crystal NiS prepared by adding silica nanospheres (50nm) close-packed templates pre-seeded by impregnation method 2 (MSC-NiS 2 ) and non-porous single crystal NiS prepared without prefabricated templates 2 (Solid-NiS 2 ) as a comparison to study the relationship between the prefabricated template and the particle pore structure.

[0043] Morphological characterization equipment: scanning electron microscope, FEI Nova620. Such as figure 2 As shown, it can be clearly seen that MSC-NiS 2 There are a large number of porous structures on the particles, while Solid-NiS 2 There are no pores on the particles, which proves the effectiveness of the preparation method of the sulfide porous single crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com