Adhesive composite wear-resistant super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating and adhesive technology, applied in the field of preparation of hydrophobic materials, can solve problems such as complex process, inability to realize large-scale preparation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

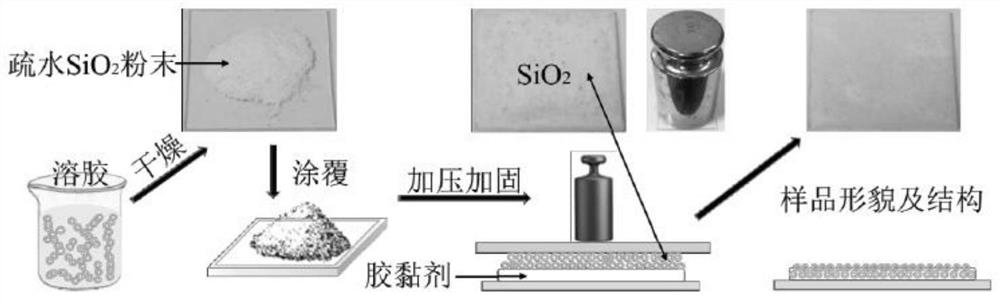

Synthetic example

[0039] Add 40 ml of ethanol, 1 ml of deionized water and 5 ml of tetraethylorthosilicate to the beaker and keep stirring. After 30 min, add 1 ml of ammonia water (27%) and continue stirring for 30 min. Finally, add 3 ml of hexamethyldisilica Amine was continuously stirred for 4 hours, and aged for one week to obtain a stable silica sol. The whole process was carried out at room temperature; then, the silica sol was conventionally dried and ground to obtain nano-silica.

[0040] The following experimental samples are all based on soda-lime glass substrates. Before use, the glass was cut into 2.5cm×2.5cm in size, ultrasonically treated with acetone, ethanol and deionized water, and blown dry with nitrogen to clean them.

Embodiment

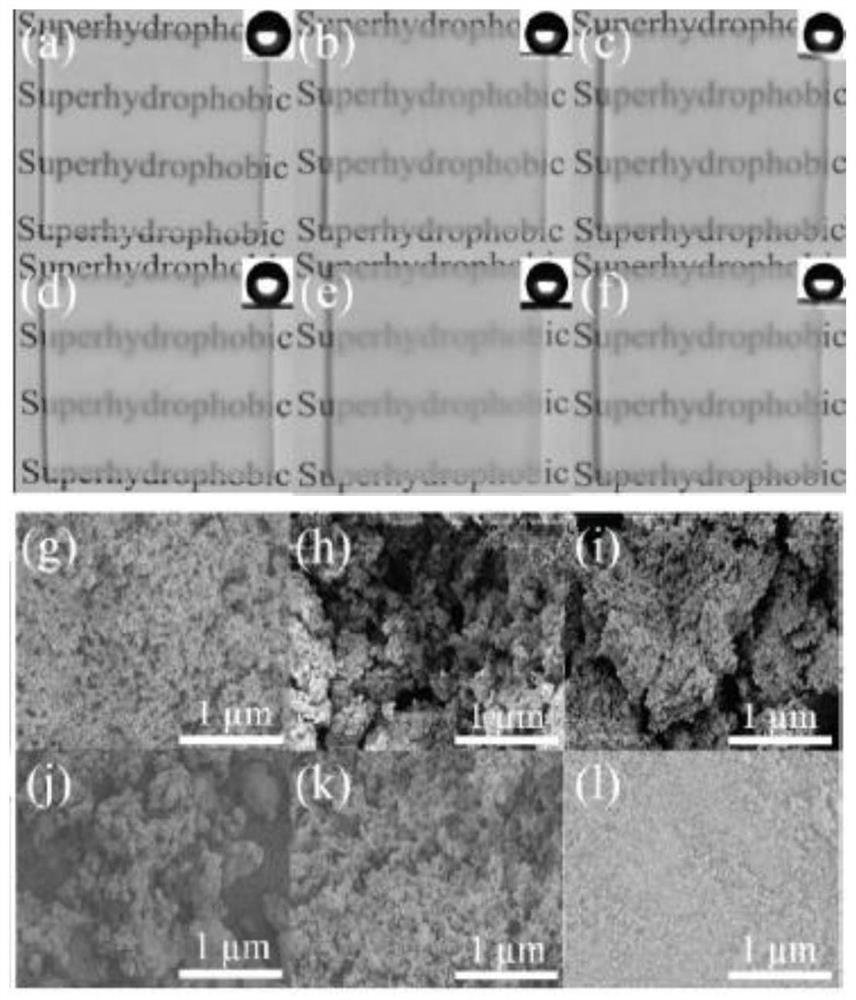

[0042] At room temperature, coat a layer of adhesive on the glass substrate, then apply nano silicon dioxide (5mL sol drying) on the adhesive, then cover with a piece of glass, place a 1Kg weight, pressurize After curing, an adhesive composite wear-resistant superhydrophobic coating is obtained, with a contact angle of 161° and a rolling angle of figure 1 , The curing time is set according to the instructions of the adhesive.

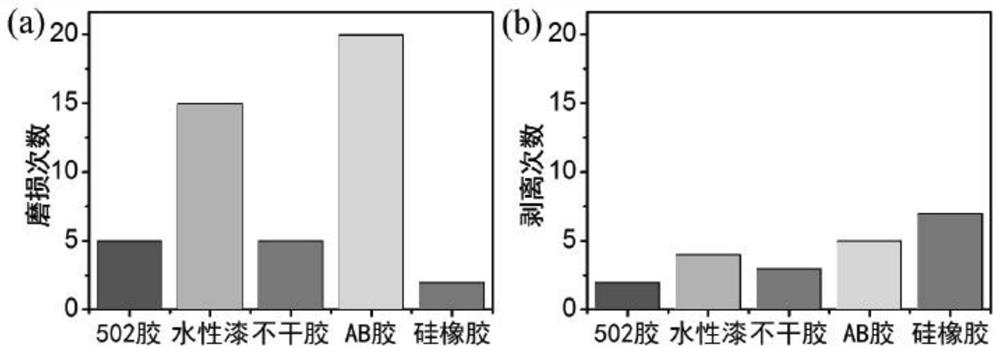

[0043] The conditions that the present invention can effectively improve the wear resistance are: 1. The strong bonding effect of the adhesive on the material; 2. The adhesive material itself combined with nano-silica has higher wear resistance; 3. The adhesive It can be mixed with nanoparticles to act as a skeleton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com