Preparation method of efficient flame-retardant polystyrene using brominated flame retardant containing active functional groups

A technology of brominated flame retardants and active functional groups, applied in the field of preparation of high-efficiency flame-retardant polystyrene, can solve problems such as poor dispersion effect, poor flame-retardant effect of polystyrene resin, poor compatibility, etc., and achieve improved flame-retardant Good effect, good environmental protection performance, reduce the effect of thermal polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] This embodiment provides a method for preparing high-efficiency flame-retardant polystyrene using a brominated flame retardant containing active functional groups. The preparation method includes the following steps:

[0033] S1 end-capping: Stir and mix styrene monomer, brominated flame retardant containing active functional groups and ethylenic monomers containing specific active functional groups. After the brominated flame retardant containing active functional groups is completely dissolved, heat up to 90°C~ Continue stirring at 140°C and carry out end-capping reaction to obtain a mixture containing brominated flame retardants with double bonds introduced at the end;

[0034] S2 pre-polymerization: adding an initiator to the mixture obtained in the S1 end-capping step to perform pre-polymerization to obtain a prepolymer;

[0035] S3 post-polymerization: transfer the prepolymer to the post-polymerization equipment to continue the copolymerization, and further devola...

Embodiment

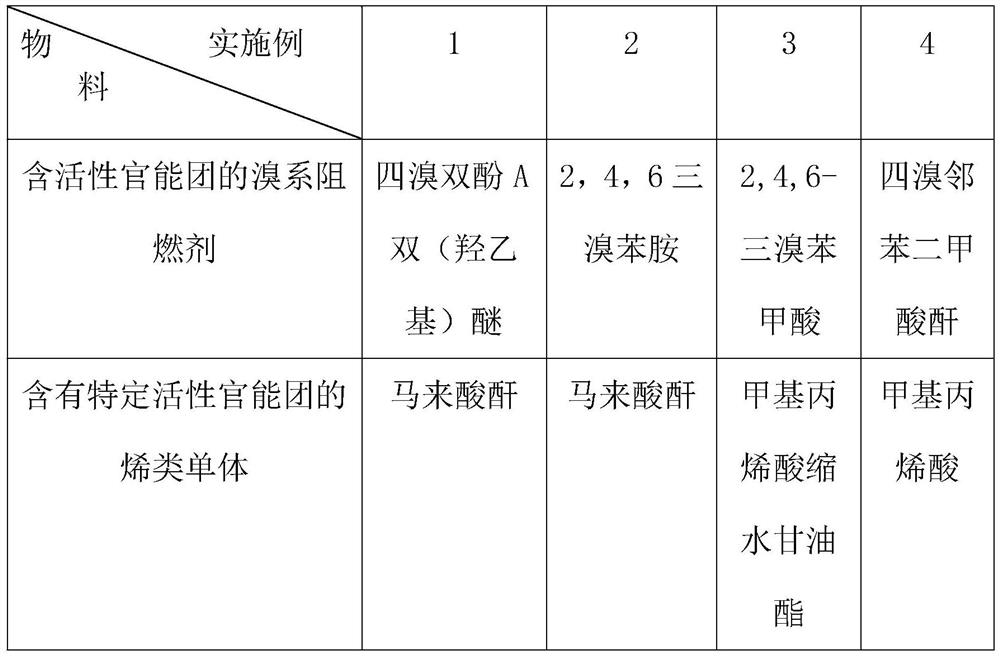

[0049] The difference between Examples 1-4 is that the selected brominated flame retardants containing active functional groups are different from the ethylenic monomers containing specific active functional groups.

[0050] Embodiment 1 is taken as an example below for description.

[0051] A preparation method for high-efficiency flame-retardant polystyrene using a brominated flame retardant containing active functional groups, comprising the following steps:

[0052] S1 capping: under the protection of inert gas, add 9750g styrene monomer, 150g brominated flame retardant containing active functional group, 50g flame retardant synergist and 50g vinyl monomer containing specific active functional group to the prepolymerization reaction In the kettle, stir and mix until the brominated flame retardant containing the active functional group is completely dissolved; then raise the temperature to 125°C and continue stirring, and perform a capping reaction for 1 hour to obtain a mi...

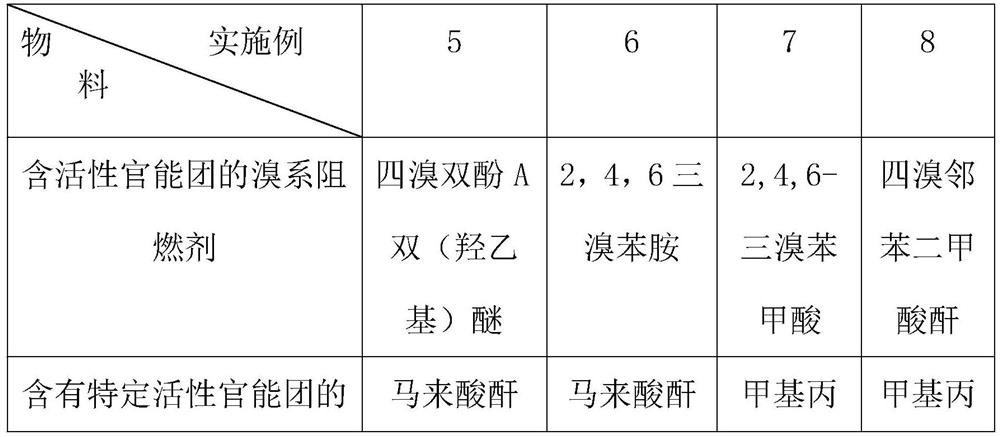

Embodiment 5

[0063] The end-capping step S1 and the prepolymerization step S2 in this embodiment are the same as those in Examples 1-4. For the post-polymerization step of the difference S3, it is specifically: the prepolymer prepared in the S2 prepolymerization step is transported to the extruder, the temperature is set at 180 ° C, the residence time of the prepolymer in the extruder for 50min. After the reaction is completed, the high-efficiency flame-retardant polystyrene resin is obtained by devolatilization through the vacuum system arranged at the end;

[0064] Wherein the used extruder is the extruder group that two screw rod diameters are 48, length-to-diameter ratio 65, connect in series.

[0065] Table 2 Embodiment 5~8 difference material type table

[0066]

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com