Oil-based drilling fluid as well as preparation method and application thereof

An oil-based drilling fluid and oil phase technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of oil-based drilling fluid viscosity and shear force increase, not suitable for operation in cold areas, oil-based drilling fluid flow It can improve the flow performance, prevent the complicated situation in the well, and prevent the pipeline blockage problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

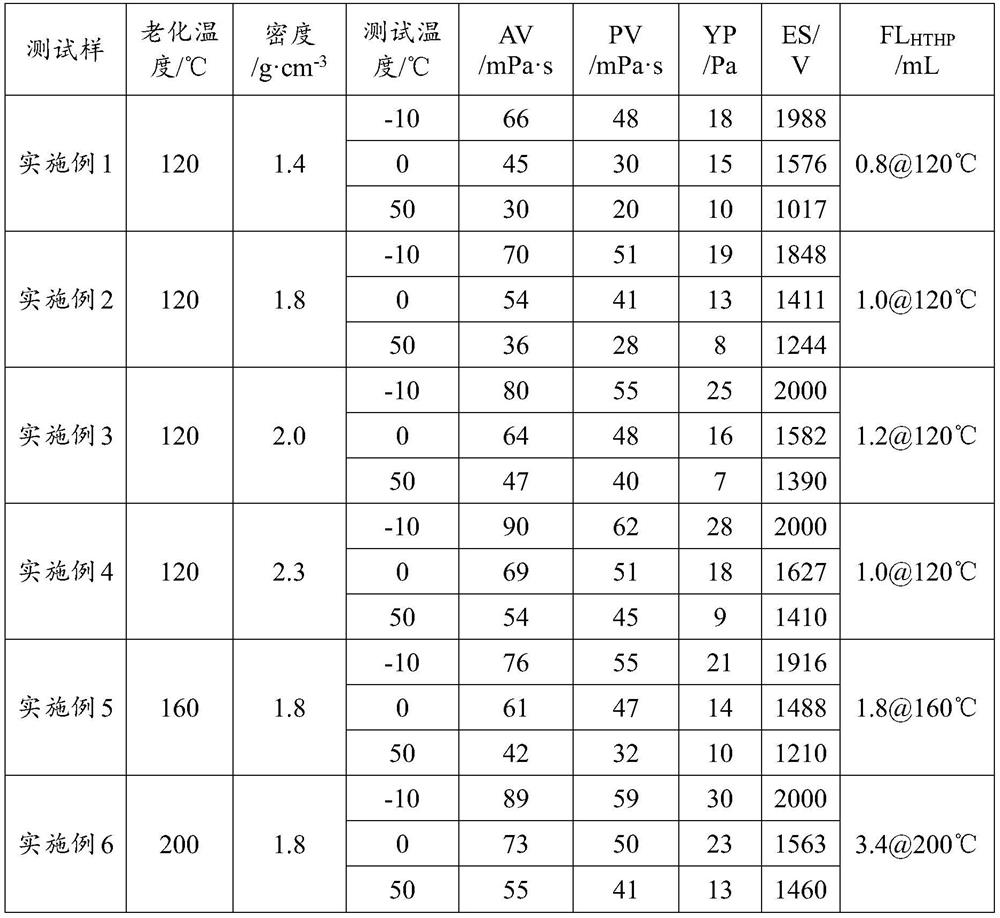

Examples

preparation example Construction

[0050] In the present invention, the preparation method of the solid emulsifier comprises:

[0051] In the present invention, the first rosin and the first maleic anhydride are mixed to carry out the Diels-Alder reaction to obtain the addition product.

[0052] In the present invention, the mass ratio of the first rosin to the first maleic anhydride is preferably 40-50:15-20, more preferably 50:15, 45:18 or 40:20. In the present invention, the first rosin preferably includes one or more of gum rosin, wood rosin and tall oil rosin, more preferably gum rosin.

[0053] In the present invention, the temperature of the Diels-Alder reaction is preferably 180-220° C., more preferably 200-210° C., and the time is preferably 2-4 h, more preferably 2-3 h. In the process of the Diels-Alder reaction, the double bond of the first rosin is isomerized into L-pimorosin at 180-220°C, forming a conjugated double bond in the same alicyclic ring, and then with maleic The acid anhydride undergoe...

Embodiment 1

[0087] (1) 50 parts by weight of gum rosin was heated to melting, 15 parts by weight of maleic anhydride was added with stirring, and the temperature was raised to 220° C. Diels-Alder reaction occurred, and the reaction time was 2h to generate an addition product;

[0088] (2) 10 parts by weight of ethylenediamine was slowly added dropwise to the generated addition product (dropping was completed in 5 minutes), and an acylation reaction occurred, and the reaction was carried out for 4 h, and the product was the initial reaction material; Add 10 parts by weight of maleic anhydride to the material, react for 1.5h;

[0089](3) adding 15 parts by weight of calcium oxide to the product of step (2), at a temperature of 80 ° C, a neutralization reaction occurs for 2 h, and the solid after cooling to room temperature is pulverized to obtain a yellow powdery intermediate product;

[0090] (4) Mix 80 parts by weight of the intermediate product, 15 parts by weight of sodium dodecylbenzen...

Embodiment 2

[0103] (1) 45 parts by weight of gum rosin was heated to melting, stirred and added 18 parts by weight of maleic anhydride, heated to 180° C., Diels-Alder reaction occurred, and the reaction time was 4h to generate addition product;

[0104] (2) Slowly add 12 parts by weight of ethylenediamine dropwise to the resulting addition product (dropping is completed in 10 minutes), and an acylation reaction occurs. The reaction is performed for 1 h, and the product is the initial reaction material; after cooling to 100 ° C, at the beginning of the reaction Add 8 parts by weight of maleic anhydride to the material, and react for 1h;

[0105] (3) adding 17 parts by weight of calcium oxide to the product obtained in step (2), at a temperature of 100° C., a neutralization reaction occurs for 1 h, and the solid after cooling to room temperature is pulverized to obtain a yellow powdery intermediate product;

[0106] (4) Mix 75 parts by weight of intermediate product, 17 parts by weight of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com