Method for purifying aluminum-silicon-iron alloy through high-temperature and low-temperature two-step remelting centrifugal separation

A centrifugal separation and ferroalloy technology, applied in the field of smelting, can solve the problems of inability to carry out high-efficiency and large-scale practical applications, and achieve significant social and economic benefits, rational use of resources, and the effect of reducing iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

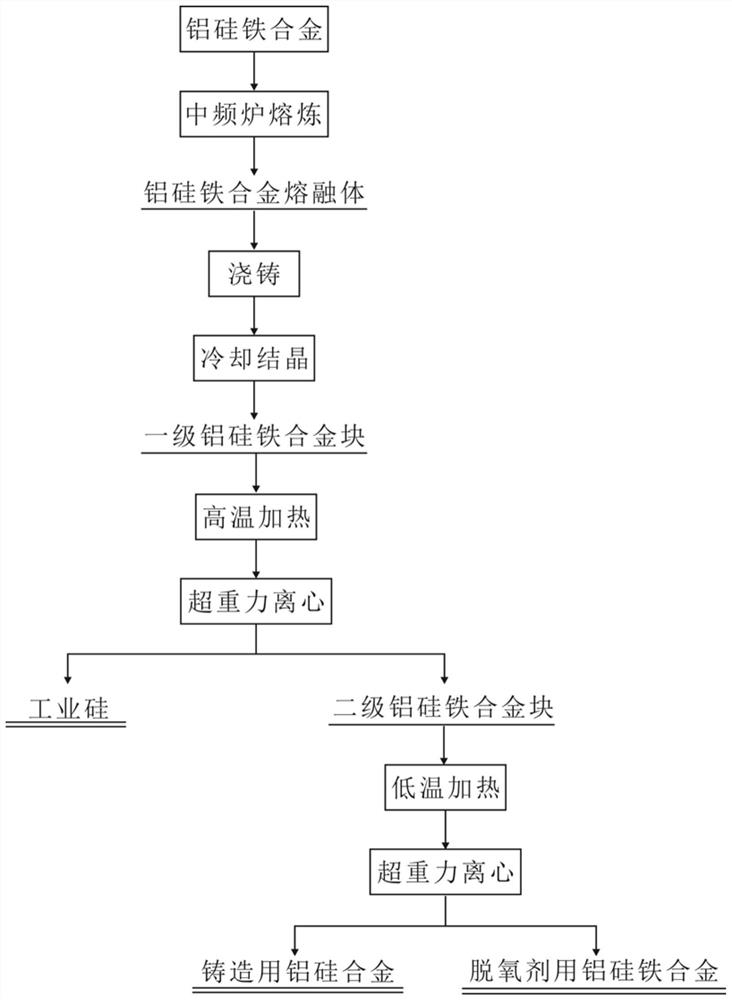

[0030] A high-temperature, low-temperature two-step remelting centrifugal separation method for purifying Al-Si-Fe alloy, the process flow chart is as follows figure 2 shown, including the following steps:

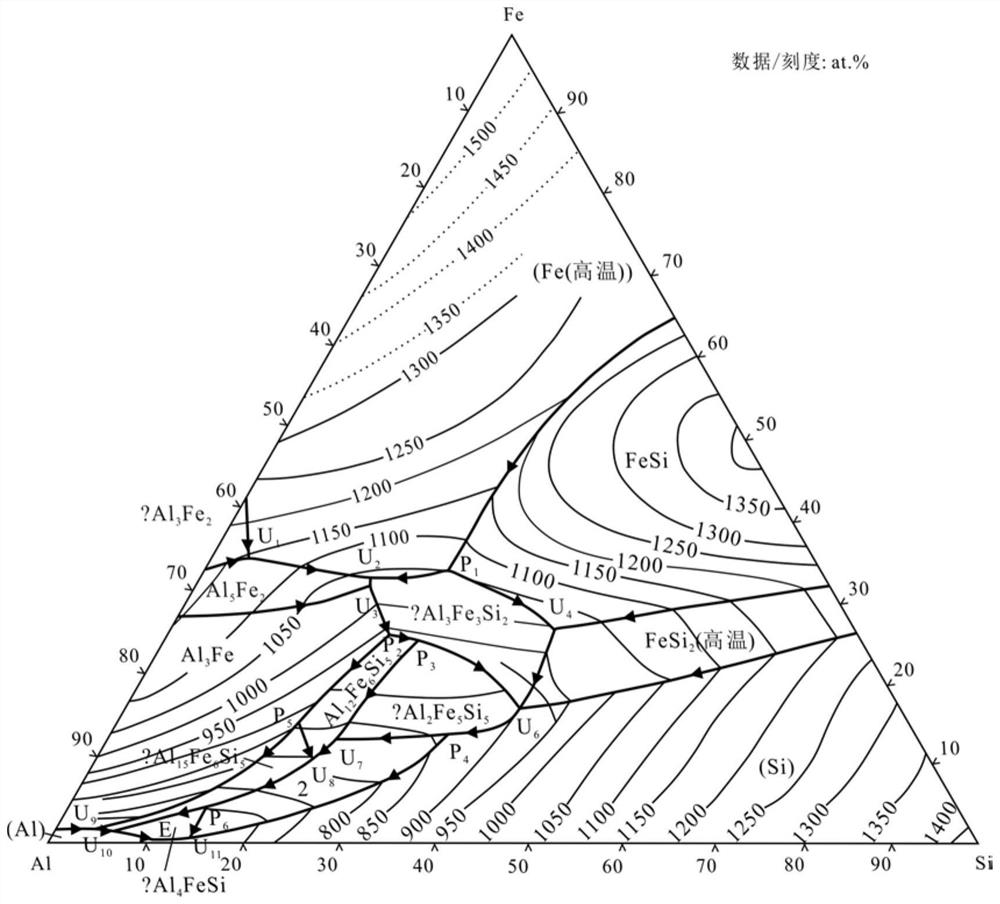

[0031] Put 100kg of Al-Si-Fe alloy into an intermediate frequency furnace for high-temperature smelting, the temperature of the molten material is 1400-1600°C, and the Al-Si-Fe alloy composition is 52.45% of Al, 41.98% of Si, and 2.65% of Fe. Al-Si-Fe alloy melt; cast the melt in a mold, then cool down to 900°C at 2°C / min, keep it at this temperature for 120min, let the alloy phase precipitate and grow, and then cool naturally to room temperature to obtain first-grade aluminum Ferrosilicon alloy block. Such as figure 1 As shown, the alloy phase diagram of the present invention shows that when the cooling temperature drops to 950-1000°C, silicon crystals first precipitate and grow up, and as the cooling temperature decreases, the silicon content in the melt gradually dec...

Embodiment 2

[0034] A high-temperature, low-temperature two-step remelting centrifugal separation method for purifying Al-Si-Fe alloy, the process flow chart is as follows figure 2 shown, including the following steps:

[0035] Put 100kg of Al-Si-Fe alloy into an intermediate frequency furnace for high-temperature smelting, the temperature of the molten material is 1400-1600°C, and the Al-Si-Fe alloy composition is 52.45% by Al, 41.98% by Si and 2.65% by Fe. Aluminum-silicon-iron alloy melt; cast the melt in a mold, then cool down to 950°C at 5°C / min, keep it at this temperature for 90min, let the alloy phase precipitate and grow, and then cool naturally to room temperature to obtain first-grade aluminum Ferrosilicon block. Such as figure 1 As shown, the phase diagram of the alloy of the present invention shows that when the cooling temperature drops to 950-1000°C, silicon crystals first precipitate and grow up. As the cooling temperature decreases, the silicon content in the melt gradu...

Embodiment 3

[0038] A high-temperature, low-temperature two-step remelting centrifugal separation method for purifying Al-Si-Fe alloy, the process flow chart is as follows figure 2 shown, including the following steps:

[0039] Put 100kg of Al-Si-Fe alloy into an intermediate frequency furnace for high-temperature smelting, the temperature of the molten material is 1400-1600°C, and the Al-Si-Fe alloy composition is 52.45% by Al, 41.98% by Si and 2.65% by Fe. Aluminum-silicon-iron alloy melt; cast the melt in a mold, then cool down to 950°C at 5°C / min, keep it at this temperature for 90min, let the alloy phase precipitate and grow, and then cool naturally to room temperature to obtain first-grade aluminum Ferrosilicon block. Such as figure 1 As shown, the phase diagram of the alloy of the present invention shows that when the cooling temperature drops to 950-1000°C, silicon crystals first precipitate and grow up. As the cooling temperature decreases, the silicon content in the melt gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com