Aluminum alloy material suitable for manufacturing sliding bearing

An aluminum alloy material and sliding bearing technology, applied in the field of aluminum alloys, can solve the problems of insufficient compliance of aluminum alloys, low plastic toughness, and unfavorable sliding bearing compliance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

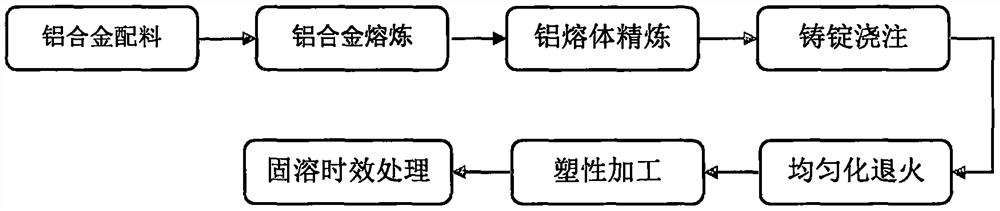

Image

Examples

Embodiment 1-9

[0030] Table 1 is the chemical composition of specific examples 1-9.

[0031] Preparation method: The raw materials used in the preparation of aluminum alloys are pure metal elements and aluminum-based master alloys. The metal elements are pure aluminum and pure zinc. Other alloying elements are added in the form of aluminum-based master alloys. Pure metal and aluminum-based master alloys The purity of the alloy is not less than 99.9%. According to the chemical composition of the alloy, it is melted in a non-vacuum induction melting furnace (or resistance furnace), and the crucible is an alumina crucible. Put the required pure aluminum and various aluminum-based intermediate alloys into the alumina crucible, and then cover with No. 1 solvent, and heat the induction furnace with electricity. After the alloy is melted, raise the temperature to 800-850°C and keep it for 30 minutes, then cool down To 720 ℃, add the required pure zinc, after the pure zinc is melted, the aluminum all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com