High-strength flame-retardant antibacterial fabric and preparation method thereof

A kind of antibacterial fabric and high-strength technology, which is applied in the direction of flame-retardant fiber, biochemical fiber treatment, fiber type, etc., can solve the problems of worker injury, high air tightness requirements of formaldehyde processing equipment, and polluted environment, so as to prolong the service life , good photocatalytic antibacterial performance, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a high-strength flame-retardant and antibacterial fabric, comprising the following steps:

[0037] (1) The preparation method of flame-retardant modified vinylon is as follows:

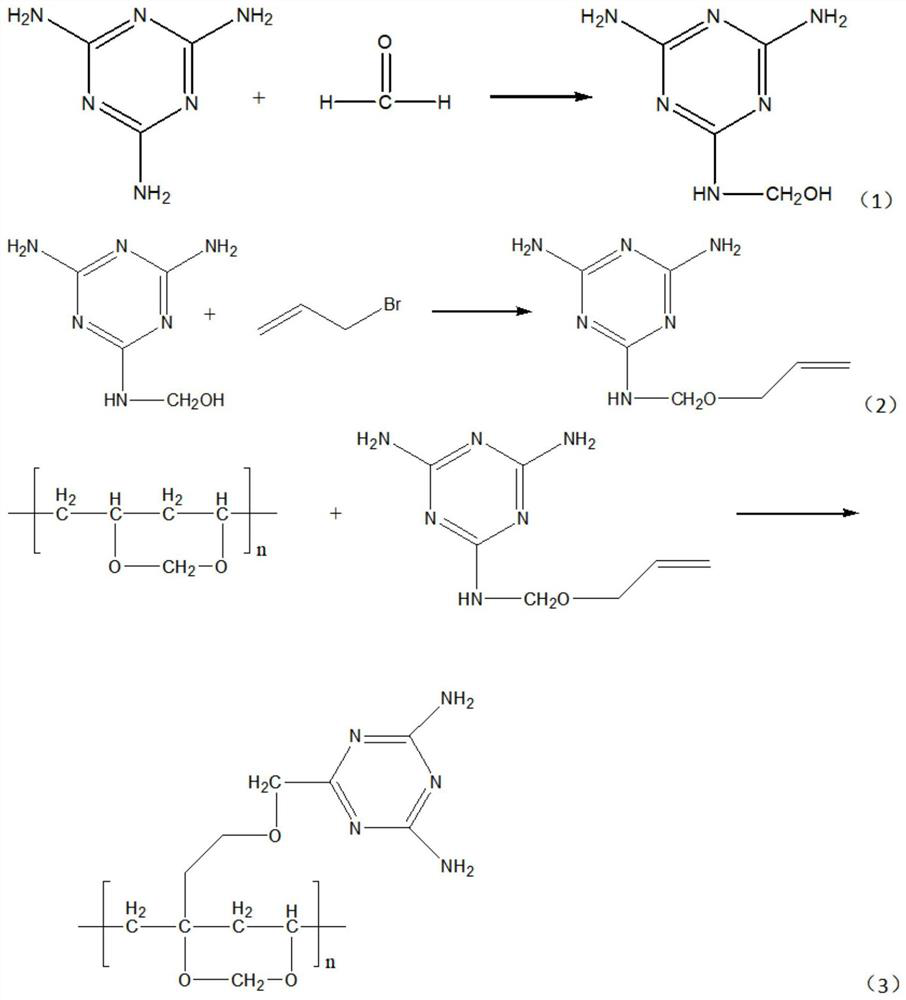

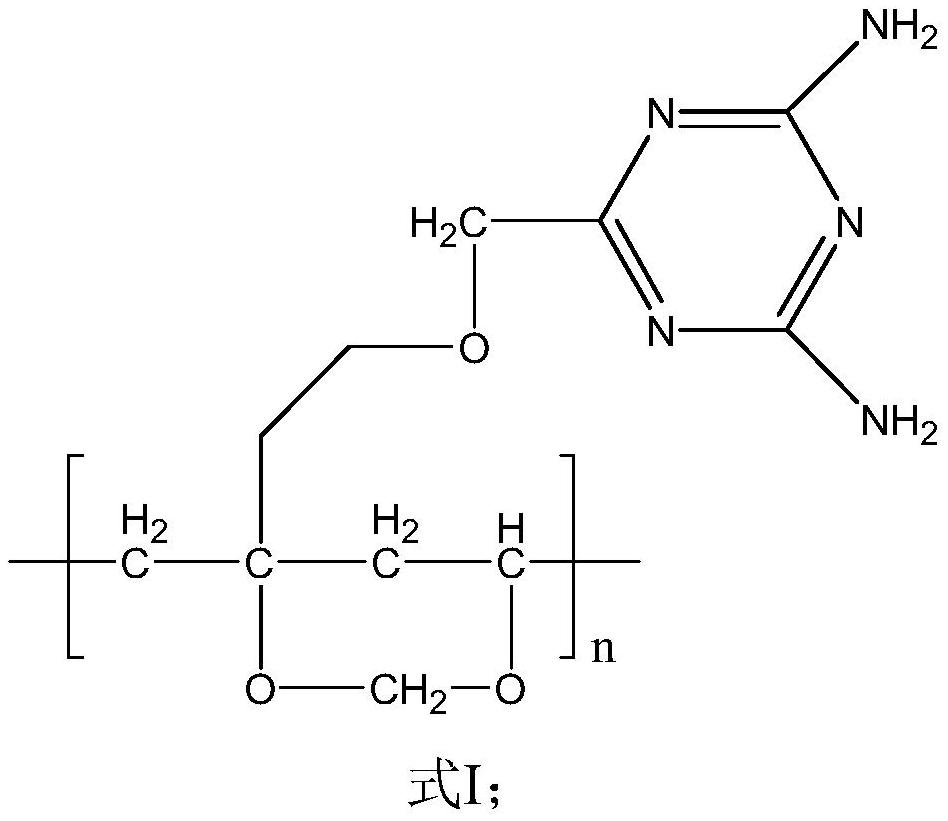

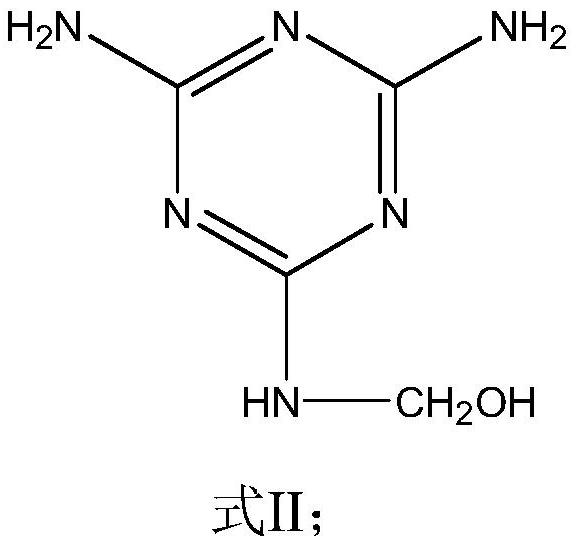

[0038] The reaction equation is as figure 1 shown.

[0039] S1. Adjust the formaldehyde solution to pH 8 with NaOH solution, add melamine, heat up to 75-85°C, react for 1h, add saturated sodium bicarbonate solution to quench the reaction, then add an equal volume of dichloromethane for extraction, take the oil phase, The solvent was removed under reduced pressure to obtain intermediate A; the ratio of methanol and melamine was 1:1;

[0040] S2. Dissolve intermediate A and 3-bromopropene in dichloromethane, heat to 70°C, add potassium carbonate, react for 3h, add saturated sodium bicarbonate solution to quench the reaction, take the organic phase, and remove the solvent under reduced pressure to obtain Intermediate B; the ratio of the amount of the intermediate A, 3-b...

Embodiment 2

[0049] This embodiment provides a high-strength flame-retardant and antibacterial fabric, comprising the following steps:

[0050] (1) The preparation method of flame-retardant modified vinylon is as follows:

[0051] The reaction equation is as figure 1 shown.

[0052] S1. Adjust the formaldehyde solution to pH 10 with NaOH solution, add melamine, heat up to 85°C, react for 2 hours, add saturated sodium bicarbonate solution to quench the reaction, then add an equal volume of dichloromethane for extraction, take the oil phase, and depressurize Remove the solvent to obtain intermediate A; the ratio of methanol and melamine is 1:1.1;

[0053] S2. Dissolve intermediate A and 3-bromopropene in chloroform, heat to 90°C, add potassium carbonate, react for 5h, add saturated sodium bicarbonate solution to quench the reaction, take the organic phase, and remove the solvent under reduced pressure to obtain Intermediate B; the ratio of the amount of the intermediate A, 3-bromopropene,...

Embodiment 3

[0060] This embodiment provides a high-strength flame-retardant and antibacterial fabric, comprising the following steps:

[0061] (1) The preparation method of flame-retardant modified vinylon is as follows:

[0062] The reaction equation is as figure 1 shown.

[0063] S1. Adjust the formaldehyde solution to pH 9 with NaOH solution, add melamine, heat up to 80°C, react for 1.5h, add saturated sodium bicarbonate solution to quench the reaction, then add an equal volume of dichloromethane for extraction, take the oil phase, and reduce The solvent is removed by pressure to obtain intermediate A; the ratio of the substance of the methanol and melamine is 1:1.05;

[0064] S2. Dissolve intermediate A and 3-bromopropene in toluene, heat to 80°C, add potassium carbonate, react for 4 hours, add saturated sodium bicarbonate solution to quench the reaction, take the organic phase, and remove the solvent under reduced pressure to obtain the intermediate B; the ratio of the amount of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com