Acetone sensor, preparation method and application

A sensor and gas sensor technology, applied in the field of gas sensor preparation, can solve the problems of ineffective control of the cavity structure, time-consuming and uneconomical manufacturing process, unfavorable wide application, etc., to achieve improved sensitivity, excellent gas-sensing characteristics, and excellent activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

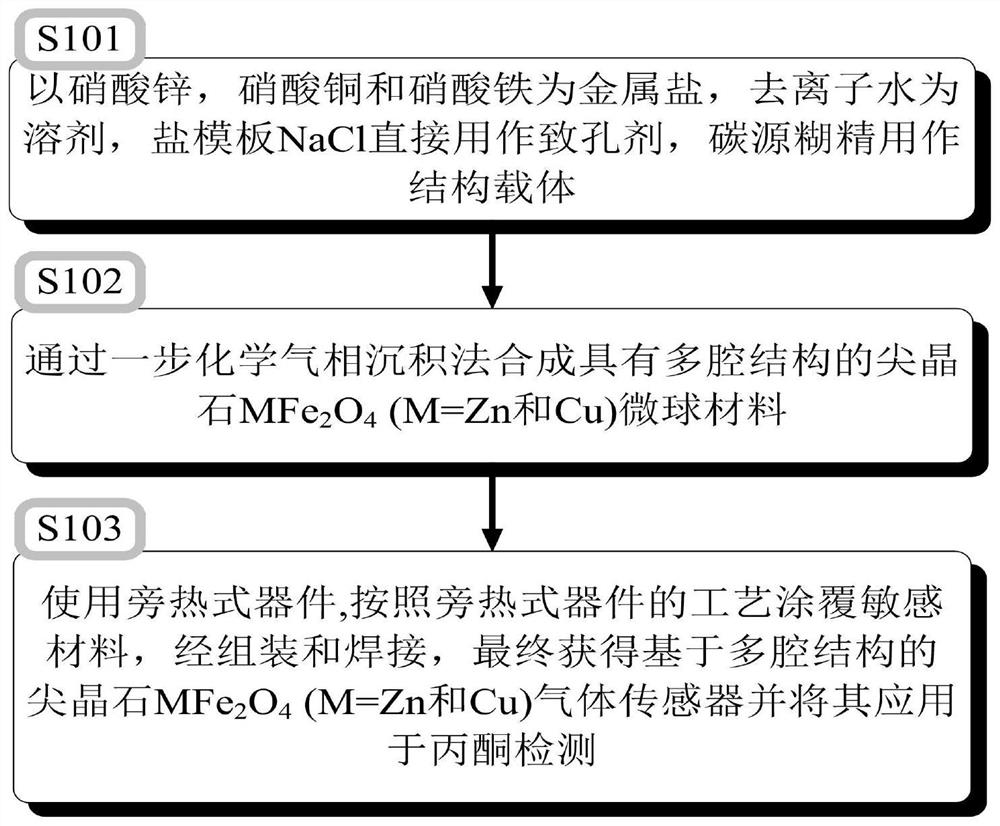

[0048] Such as figure 1 As shown, the preparation method of the acetone sensor provided by the embodiment of the present invention comprises the following steps:

[0049] S101, zinc nitrate, copper nitrate and iron nitrate are used as metal salts, deionized water is used as solvent, salt template NaCl is directly used as porogen, and carbon source dextrin is used as structural carrier;

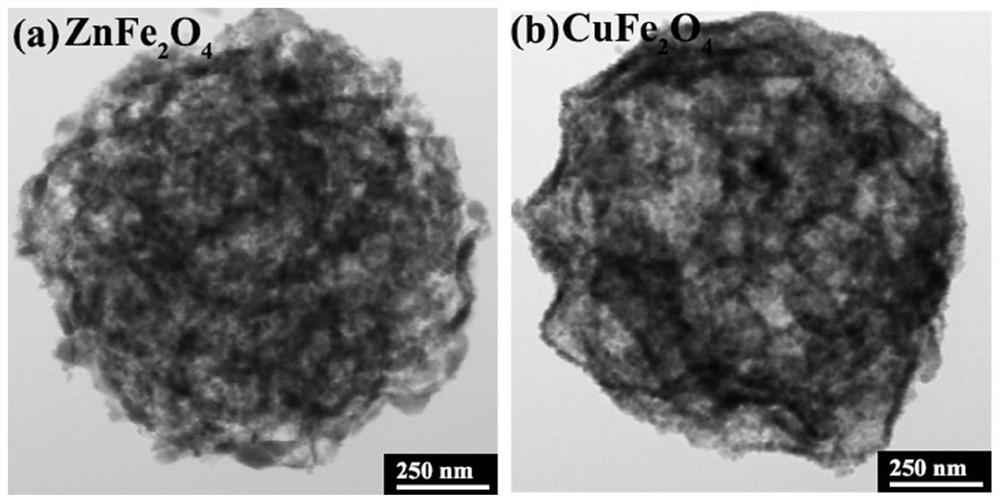

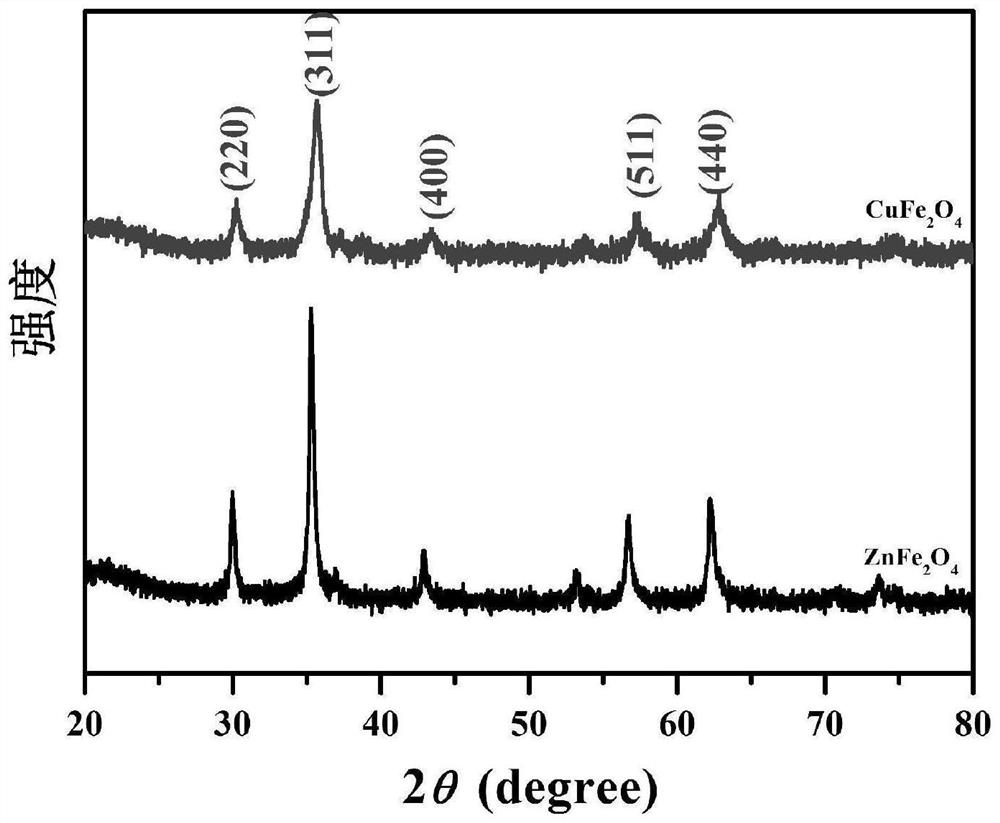

[0050] S102, Synthesis of spinel MFe with multi-cavity structure by one-step chemical vapor deposition 2 o 4 Microsphere material; Wherein, the spinel MFe 2 o 4 Including M=Zn and Cu;

[0051] S103, use the side-heating device, apply sensitive materials according to the process of the side-heating device, assemble and weld, and finally obtain the spinel MFe based on the multi-cavity structure 2 o 4 (M=Zn and Cu) gas sensor and its application to acetone detection.

[0052] Multi-cavity spinel MFe of the present invention 2 o 4 (M=Zn and Cu) The contents of the chemical reagents in the...

Embodiment 2

[0073] Such as figure 1 As shown, the preparation method of the acetone sensor provided by the embodiment of the present invention comprises the following steps:

[0074] S101, zinc nitrate, copper nitrate and iron nitrate are used as metal salts, deionized water is used as solvent, salt template NaCl is directly used as porogen, and carbon source dextrin is used as structural carrier;

[0075] S102, Synthesis of spinel MFe with multi-cavity structure by one-step chemical vapor deposition 2 o 4 Microsphere material; Wherein, the spinel MFe 2 o 4 Including M=Zn and Cu;

[0076] S103, use the side-heating device, apply sensitive materials according to the process of the side-heating device, assemble and weld, and finally obtain the spinel MFe based on the multi-cavity structure 2 o 4 (M=Zn and Cu) gas sensor and its application to acetone detection.

[0077] Multi-cavity spinel MFe of the present invention 2 o 4 (M=Zn and Cu) The contents of the chemical reagents in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com