Method for treating rural multi-source organic solid waste

A technology for organic solids and wastes, applied in organic fertilizers, microbial treatment, bio-organic part treatment, etc., can solve the problems of high treatment cost of high-temperature bacterial agents, unsuitable high-temperature aerobic fermentation, etc., to avoid fertility decline and reduce application cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

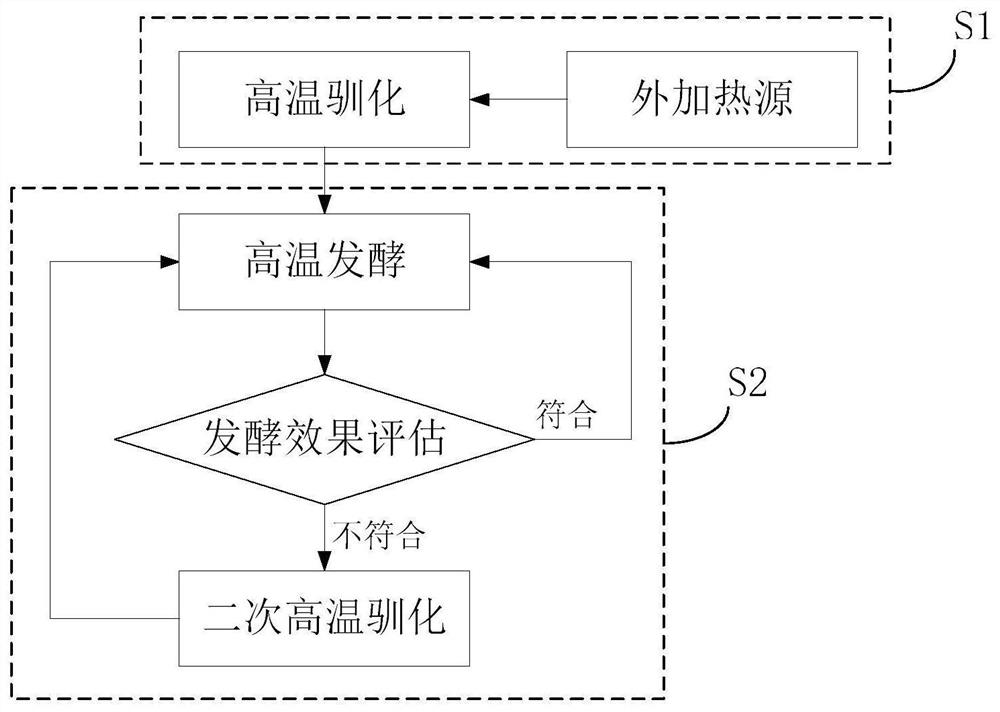

[0054] The method for processing rural multi-source organic solid waste provided in this embodiment includes the following steps:

[0055] Step S1, mix chicken manure, milk powder, and rice husk according to the mass ratio of 1:0.5:1, wherein the moisture content of chicken manure is 80%, the moisture content of milk powder is 15%, and the moisture content of rice husk is 15%, to obtain high temperature The mixture of domesticated bacteria, the carbon-nitrogen ratio of the domesticated mixture of high-temperature bacteria is 15:1, and the water content of the mixture of domesticated high-temperature bacteria is 40%. Acclimate the high-temperature bacteria acclimation mixture at 80°C for 2 hours, and the bacterial population density after acclimatization is ≥1×10 9 per g, meet the requirements of bacterial population density, and obtain the finished product of high-temperature bacteria domestication.

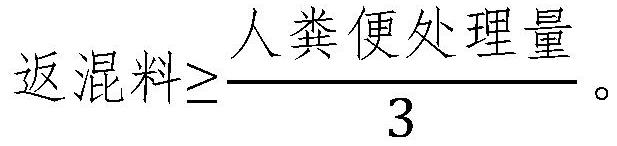

[0056] Step S2, mixing human feces to be treated, finished products domesti...

Embodiment 2

[0061] Step S1, mix chicken manure, milk powder, and rice husk according to the mass ratio of 1:0.5:1, wherein the moisture content of chicken manure is 80%, the moisture content of milk powder is 15%, and the moisture content of rice husk is 15%, to obtain high temperature Bacteria acclimatization mixture, the carbon-nitrogen ratio of the high-temperature bacteria-acclimation mixture is 12:1, and the moisture content of the high-temperature bacteria-acclimation mixture is 40%. Acclimate the high-temperature bacteria acclimation mixture at 80°C for 2 hours, and the bacterial population density after acclimatization is ≥1×10 9 per g, meet the requirements of bacterial population density, and obtain the finished product of high-temperature bacteria domestication.

[0062] Step S2. Mix human feces to be treated, finished products domesticated by high-temperature bacteria, and rice husks at a mass ratio of 4:1:1, wherein the moisture content of human feces to be treated is 62%, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com