Technological combination method for removing VOCs and odor from polyolefin resin

The technology of a polyolefin resin and a combination method is applied in the field of solving the combination of resin VOCs removal and product odor, which can solve the problems of high control severity, narrow operating temperature range, complicated operation, etc., and achieves easy maintenance and operation and reduces energy consumption. , The effect of reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

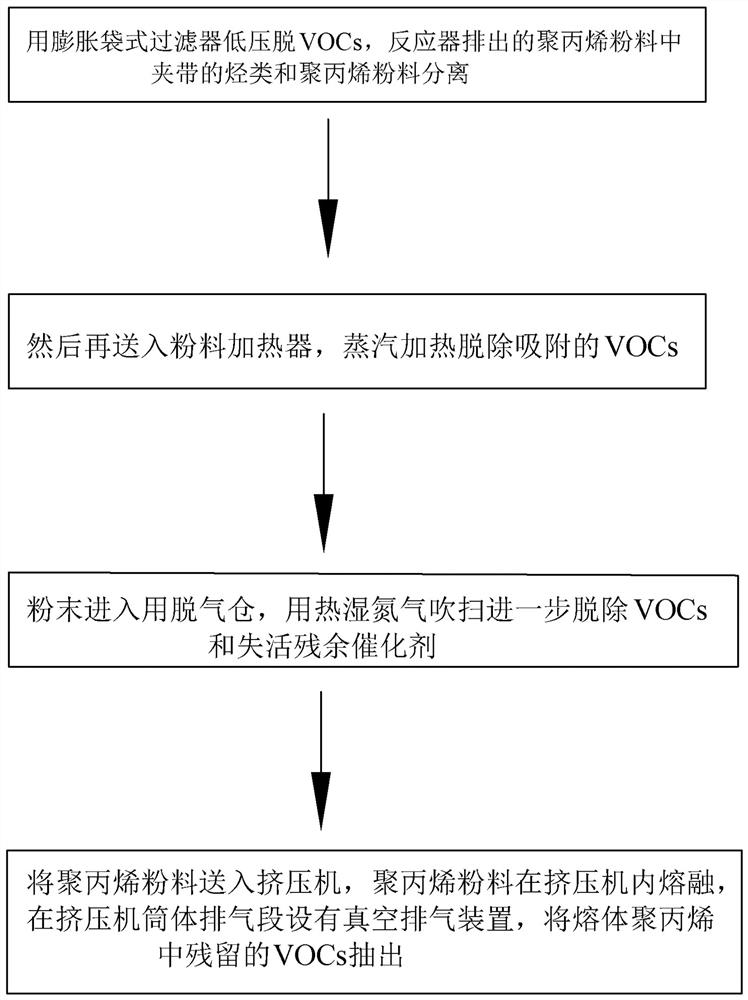

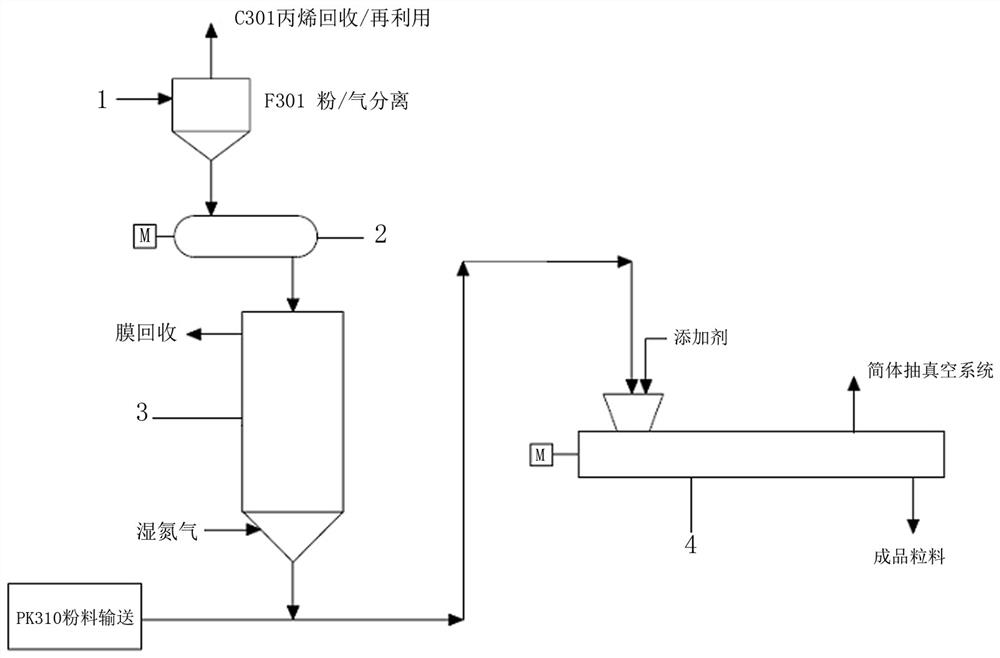

[0035] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with specific examples of gas-phase polypropylene process technology. The embodiment of this combined technology system is applicable to the resin removal of VOCs and odors in a 200,000 tons / year gas-phase polypropylene plant. For the embodiment of the combined process system, see figure 1 , figure 2 .

[0036] In the current mainstream polypropylene process analysis and headspace gas chromatography research, it is found that the characteristic components of the volatile content and odor of polypropylene powder are mainly the trace propylene oligomers produced in the process of propylene polymerization, such as isomerization Chemicalized C6, C9 and C12 alkane components. Except for some C6 components that may be brought into the hexane raw material, the addition of propylene ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com