(Methyl) acrylate adhesive composition

A technology of acrylates and adhesives, applied in the direction of ester copolymer adhesives, adhesives, adhesive types, etc., can solve the problem of initial adhesiveness or decreased adhesiveness, poor compatibility, pressure-sensitive adhesive bonding over time Stability and storage stability deterioration and other issues, to achieve sufficient adhesive force and weather resistance, good adhesion over time stability and storage stability, the appropriate effect of adhesion reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

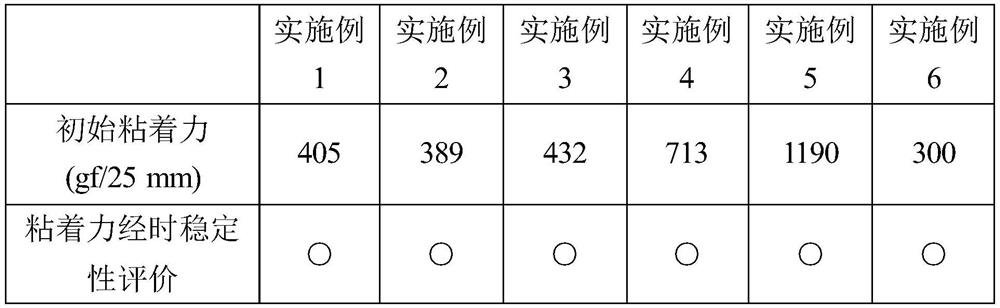

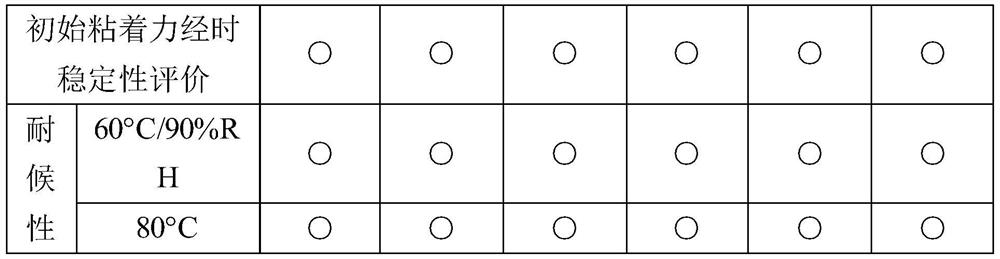

Examples

preparation example 1

[0059] Preparation Example 1: Preparation of Reactive Silane Copolymer I

[0060] With 50 parts by weight of n-butyl acrylate, 50 parts by weight of methyl acrylate, 20 parts by weight of 3-methacryloxypropyltrimethoxysilane (KBM-503, purchased from Shin-Etsu Chemical Industry, Japan), 1 After mixing parts by weight of 4-hydroxybutyl acrylate and 78 parts by weight of methyl ethyl ketone, nitrogen was passed through to remove oxygen to form solution A. Mix 0.36 parts by weight of azobisisobutyronitrile (AIBN) and 20 parts by weight of methyl ethyl ketone, heat to 85°C and start adding solution A. After the reaction is complete, reactive silane copolymer solution A can be prepared ', is a mixture of reactive silane copolymer I and methyl ethyl ketone, and the reactive silane copolymer I contains 0.0975 weight percent of hydroxyl functional groups and has a weight average molecular weight of 75,900.

preparation example 2

[0061] Preparation Example 2: Preparation of Reactive Silane Copolymer II

[0062] 50 parts by weight of n-butyl acrylate, 50 parts by weight of methyl acrylate, 20 parts by weight of 3-methacryloxypropyl trimethoxysilane (KBM-503, purchased from Shin-Etsu Chemical Industry, Japan), 5 After mixing parts by weight of 2-hydroxyethyl methacrylate and 82 parts by weight of methyl ethyl ketone, nitrogen gas was passed through to remove oxygen to form solution B. Mix 0.36 parts by weight of azobisisobutyronitrile (AIBN) and 20 parts by weight of methyl ethyl ketone, heat to 85°C and start adding solution B. After the reaction is complete, reactive silane copolymer solution B can be prepared ', is a mixture of reactive silane copolymer II and methyl ethyl ketone, and the reactive silane copolymer II contains 0.522 weight percent of hydroxyl functional groups and has a weight average molecular weight of 152,000.

Embodiment 1

[0063] Embodiment 1: Preparation of adhesive composition

[0064] Get 63 parts by weight of n-butyl acrylate, 20 parts by weight of 2-phenoxyethyl acrylate, 15 parts by weight of methyl acrylate, 1.5 parts by weight of acrylic acid, 0.8 parts by weight of methacrylic acid-2-hydroxyethyl The ester (2-HEMA) was mixed with 150 parts by weight of ethyl acetate. After nitrogen gas was passed through the mixed solution to remove oxygen for 0.5 hours, 0.065 parts by weight of azobisisobutyronitrile (AIBN) was added and the temperature was raised to 65°C for reaction. After the reaction was completed, a (meth)acrylate polymer solution could be obtained, which was a mixture of (meth)acrylate polymer and ethyl acetate, and the acid value of the (meth)acrylate polymer was 13.9mgKOH / g And the weight average molecular weight was 1,400,000.

[0065] The above (meth)acrylate polymer solution was taken and diluted with ethyl acetate (EAC) to a solid content of 18%. Take 100 parts by weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com