Preparation method of bismuth vanadate yellow pigment for visible light catalytic sterilization and product prepared by preparation method

The technology of a yellow pigment and bismuth vanadate is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of uncharacterized copper ion antibacterial performance, complicated preparation process, and high equipment requirements, and achieve Ease of large-scale production, simple preparation process, and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

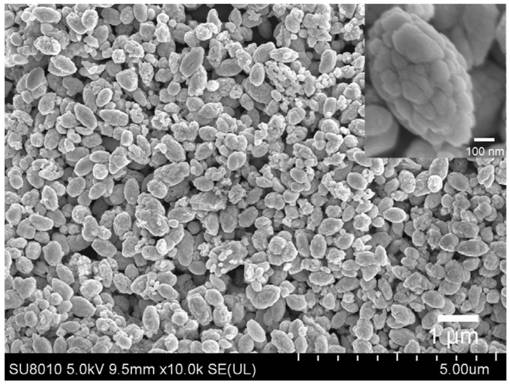

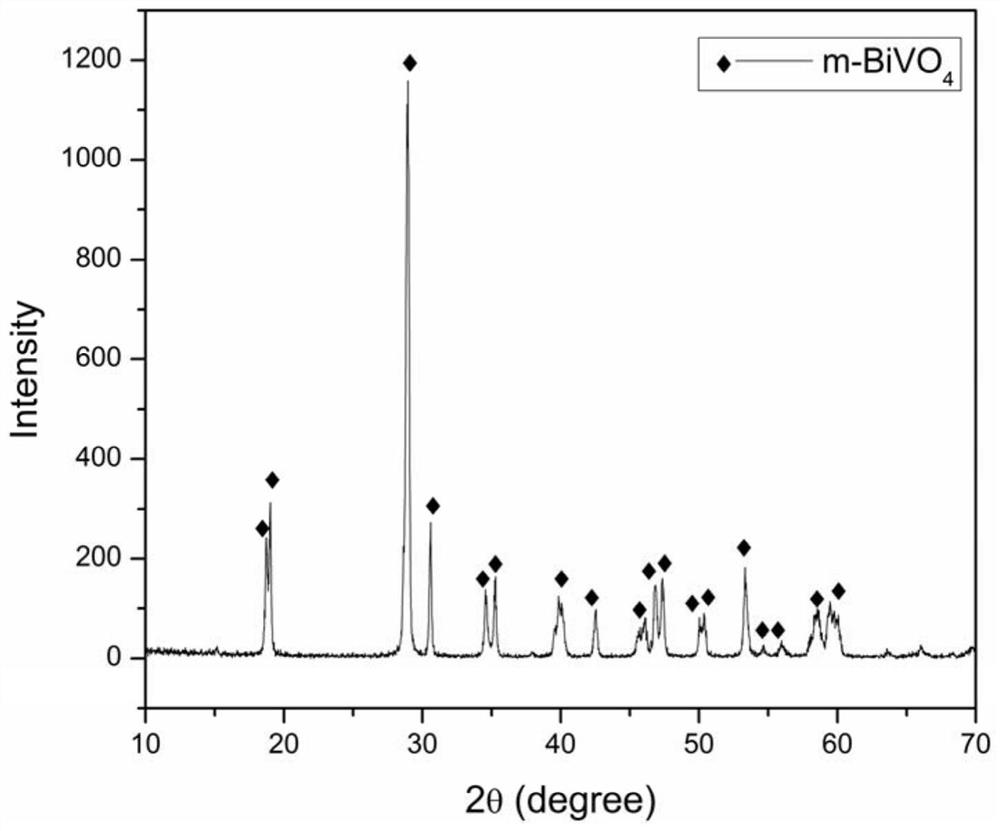

[0020] In this embodiment, a method for preparing a yellow pigment of bismuth vanadate for catalytic sterilization by visible light, the steps are as follows:

[0021] (1) Take by weighing 1.358g bismuth nitrate pentahydrate, 0.588g citric acid (according to molar ratio bismuth nitrate pentahydrate: citric acid=1: 1) be dissolved in the mixed solution that is made up of 30mL deionized water and 2mL dilute nitric acid, room temperature After stirring until dissolved, solution A is obtained;

[0022] (2) Weigh 0.3276g of ammonium metavanadate and dissolve it in a mixed solution consisting of 30mL of deionized water and 1mL of dilute nitric acid, stir at room temperature until dissolved to obtain solution B; then add the above solution B dropwise to solution A and mix , and adjust the pH value of the mixed solution to 7 with ammonia water, and stir for 60 minutes to obtain a bismuth vanadate precursor solution;

[0023] (3) Place the above-mentioned bismuth vanadate precursor so...

Embodiment 2

[0026] This embodiment differs from Embodiment 1 in that:

[0027] The consumption of bismuth nitrate pentahydrate is 0.3395g, the consumption of citric acid is 0.294g (according to molar ratio bismuth nitrate pentahydrate: citric acid=1: 2);

[0028] The consumption of ammonium metavanadate is 0.0819g;

[0029] The chromaticity values of the bismuth vanadate yellow pigment prepared in this example are L*=71.59, a*=10.07, b*=81.18.

Embodiment 3

[0031] This embodiment differs from Embodiment 1 in that:

[0032] Using bismuth trichloride and ammonium metavanadate as bismuth source and vanadium source respectively;

[0033] The pH value in step (2) is 10; The heating temperature in step (3) is 300 ℃;

[0034] The chromaticity values of the bismuth vanadate yellow pigment prepared in this example are L*=70.73, a*=12.55, b*=80.54.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com