Safe nail shooting tablet and preparation method thereof

A tablet and safe technology, which is applied in the field of safe nailing tablets and its preparation, can solve the problems of insufficient combustion, small thrust, easy moisture absorption and caking, etc., to facilitate early installation and construction operations, prevent moisture absorption and caking, and improve sensitivity good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

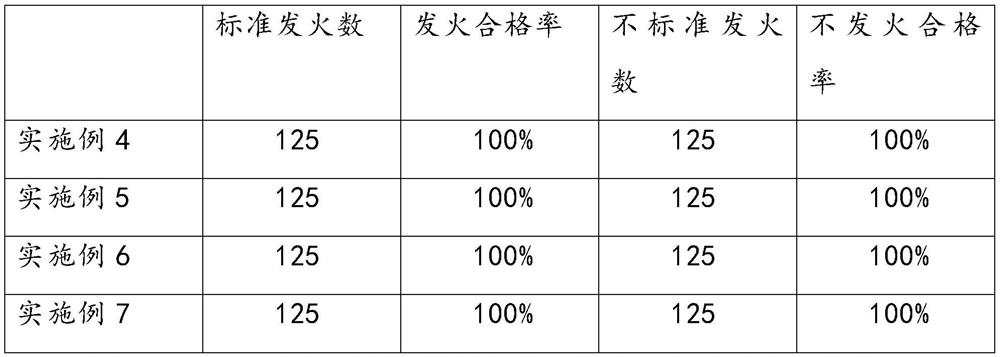

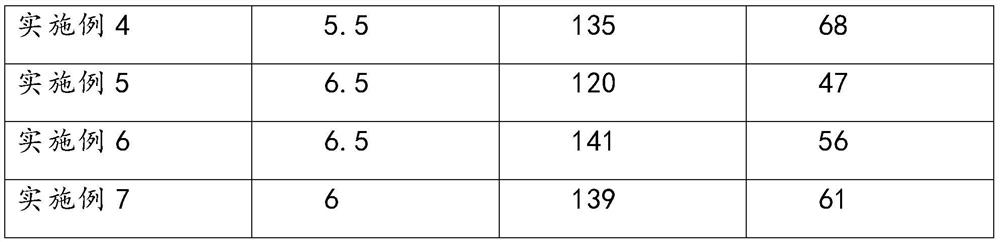

Examples

Embodiment 1

[0031] The present embodiment prepares a kind of moisture-proof ammonium perchlorate, and concrete implementation process is as follows:

[0032] Step A1: Take the agitator equipped with a gas replacement protection device, drive out the air in the agitator with dry nitrogen, add 2kg of commercially available ammonium perchlorate to the agitator, and then add tetrahydrofuran to the agitator until Submerge ammonium perchlorate in tetrahydrofuran, turn on the agitator until the ammonium perchlorate is suspended in tetrahydrofuran, keep stirring, slowly add acetone to the agitator, and observe the dissolution of ammonium perchlorate through the sight glass until the perchlorate The ammonium is completely dissolved, stop adding acetone, pump the mixed solution into the crystallizer, depressurize the mixed solution to make the acetone volatilize, and the acetone is almost volatilized, then the mixed solution is suction filtered, and the concentrated solution vacuumed to 2kPa, And h...

Embodiment 2

[0036] The present embodiment prepares a kind of moisture-proof ammonium perchlorate, and concrete implementation process is as follows:

[0037] Step A1: Take the agitator equipped with a gas replacement protection device, drive out the air in the agitator with dry nitrogen, add 2kg of commercially available ammonium perchlorate to the agitator, and then add tetrahydrofuran to the agitator until Submerge ammonium perchlorate in tetrahydrofuran, turn on the agitator until the ammonium perchlorate is suspended in tetrahydrofuran, keep stirring, slowly add acetone to the agitator, and observe the dissolution of ammonium perchlorate through the sight glass until the perchlorate Ammonium is completely dissolved, stop adding acetone, pump the mixed solution into the crystallizer, depressurize the mixed solution to make the acetone volatilize, and the acetone is almost volatilized, then the mixed solution is suction filtered, and the concentrated solution of the suction filter is vac...

Embodiment 3

[0041]Get potassium dichromate, potassium nitrate, tetrazene, barium nitrate, lead trinitroresorcinol and lead dioxide to pass through 200 mesh screens respectively, get the powder under the sieve, and follow the steps of potassium dichromate, potassium nitrate, Tetraazene, barium nitrate, lead trinitroresorcinol and lead dioxide are added into the pneumatic powder mixer according to the quantity and quality 10.5:2.2:0.7:6.7:5.9:1.3 and mixed evenly to make superfine reaction powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com