A kind of suyan cream and preparation method thereof

A kind of makeup cream and preparation technology, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc. It can solve the problems of ignoring makeup wear time, closing pores, and having to remove makeup, so as to improve skin barrier, balance oil secretion, Strong concealer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0202] Table 4 shows the components and proportions of the plain face cream in Examples 1-5.

[0203] Table 4 components and proportions of plain cream

[0204]

[0205]

Embodiment 1

[0206] Embodiment 1 The preparation process of plain makeup cream comprises the following steps:

[0207] 1) After dispersing the A-phase sodium hyaluronate, sodium polyacrylate and sodium glucoheptonate powder uniformly with alcohol (glycerol / butanediol), add it into the stirred water, heat up to 80°C until it is completely dissolved, and keep the temperature for 20 minutes. Minute sterilization, defoaming, spare;

[0208] 2) After mixing all the raw materials of phase B, heat to 80 ° C, stir and melt into a liquid, keep warm, and reserve;

[0209] 3) Turn on the homogenization, slowly add the A-phase mixed solution to the B-phase mixed solution, homogenize for 3 minutes, until it is completely emulsified and uniform, and cool down after defoaming;

[0210] 4) Cool down to 70°C, add each raw material of phase C, and homogenize for 2 minutes until uniform;

[0211] 5) Cool down to 45°C, add pre-dissolved phase D, phase E and phase F in turn, and stir well (weak homogenizatio...

Embodiment 2

[0213] The preparation process of embodiment 2 plain makeup cream comprises the following steps:

[0214] 1) After the A-phase sodium hyaluronate, sodium polyacrylate, and sodium glucoheptonate powder are uniformly dispersed with alcohol (glycerol / butanediol), they are added to the stirred water, and the temperature is raised to 81° C. to be completely dissolved. Minute sterilization, defoaming, spare;

[0215] 2) After mixing all the raw materials of phase B, heat to 81°C, stir and melt into a liquid, keep warm, and reserve;

[0216] 3) Turn on the homogenization, slowly add the A-phase mixed solution to the B-phase mixed solution, homogenize for 4 minutes, until it is completely emulsified and uniform, and cool down after defoaming;

[0217] 4) Cool down to 75°C, add each raw material of phase C, and homogenize for 3 minutes until uniform;

[0218] 5) Cool down to 45°C, add pre-dissolved phase D, phase E and phase F, and stir well (weak homogenization for 0.5-1 minutes to ...

PUM

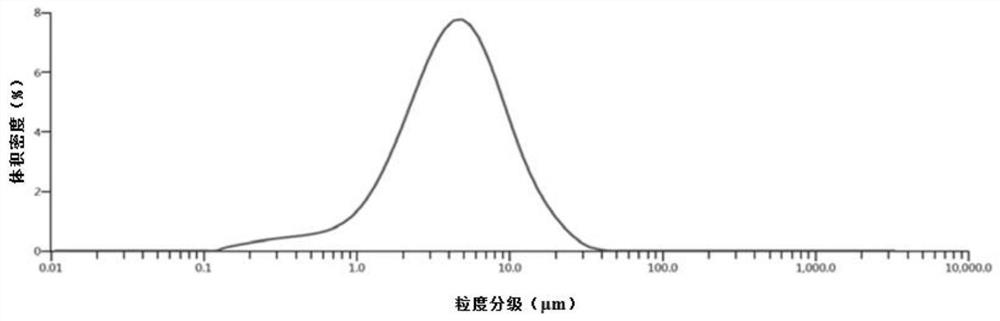

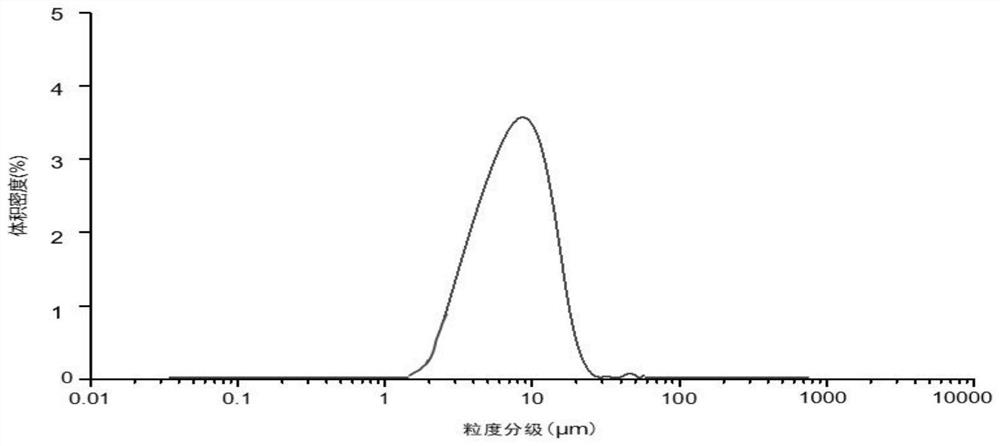

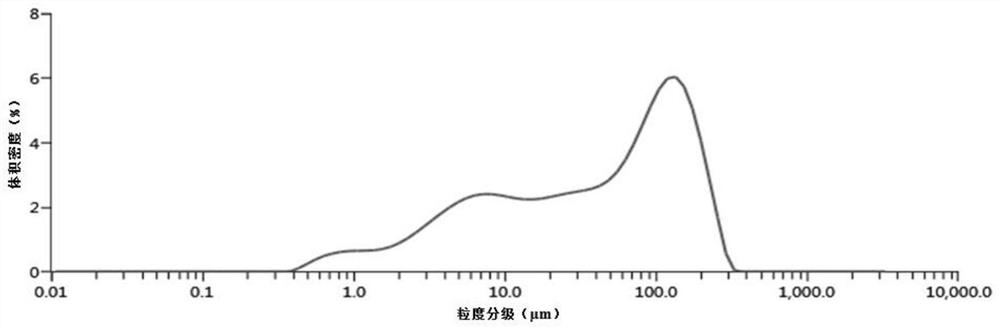

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com