Micro-nano viscosity-reducing plugging agent for oil-based drilling fluid and preparation method of micro-nano viscosity-reducing plugging agent

An oil-based drilling fluid, micro-nano technology, applied in chemical instruments and methods, drilling compositions, etc., to achieve the effects of increasing demulsification voltage, reducing surface roughness, and reducing high-temperature and high-pressure filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

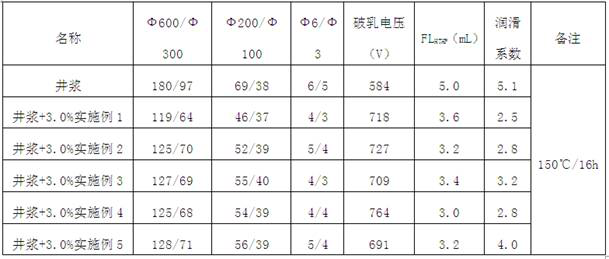

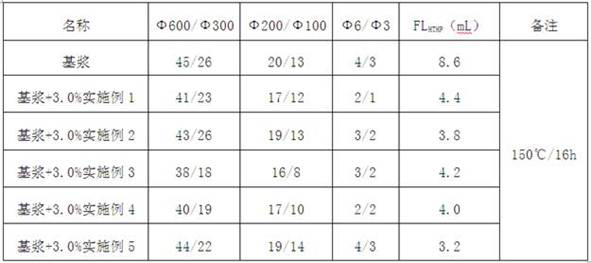

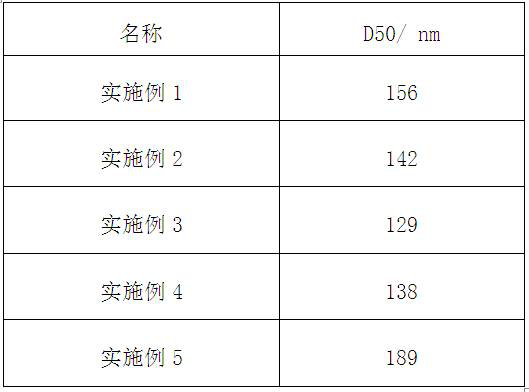

Examples

Embodiment 1

[0028] Preparation:

[0029] Petroleum resin: 38 parts of C9 petroleum resin; organic acid: 15 parts of methacrylic acid; crosslinking agent: 0.5 part of γ-(methacryloyloxy)propyltrimethoxysilane; emulsifier: sorbitan oleate 6 parts; initiator: 0.6 parts of dibenzoyl peroxide; first solvent: 25 parts of acetone; second solvent: mineral spirits D100: 110 parts.

[0030] Processing:

[0031] Step 1) Weigh the petroleum resin and the first solvent in a three-necked flask, and dissolve at 130°C for 1 hour;

[0032] Step 2) Continue to add emulsifier and mix for 20 minutes;

[0033] Step 3) At 90°C, pass nitrogen gas into the feed solution obtained in step 2) for 1 hour, then add an initiator, dropwise add an organic acid and a crosslinking agent to obtain a mixed solution;

[0034] Step 4) Add the second solvent to the mixed solution obtained in step 3), stir and disperse at a high speed to obtain the final product.

Embodiment 2

[0036] Preparation:

[0037] Petroleum resin: 10 parts of C5 petroleum resin; organic acid: 5 parts of maleic anhydride; crosslinking agent: 0.25 parts of N,N-methylenebisacrylamide; emulsifier: 3 parts of sorbitan oleic acid triester ; Initiator: 0.2 parts of azobisisobutyronitrile; first solvent: 10 parts of acetone and toluene (mass ratio 3:2); second solvent: 50 parts of white oil 3#.

[0038] Processing:

[0039] Step 1) Weigh the petroleum resin and the first solvent in a three-necked flask, and dissolve at 80°C for 2 hours;

[0040] Step 2) Continue to add emulsifier and mix for 50 minutes;

[0041] Step 3) At 120°C, pass nitrogen gas into the feed solution obtained in step 2) for 30 minutes, then add an initiator, dropwise add an organic acid and a crosslinking agent to obtain a mixed solution;

[0042] Step 4) Add the second solvent to the mixed solution obtained in step 3), stir and disperse at a high speed to obtain the final product.

Embodiment 3

[0044] Petroleum resin: 24 parts of C5 / C9 copolymer resin; organic acid: 12.5 parts of methylbutenedioic acid; crosslinking agent: 0.2 parts of vinyl tris (β-methoxyethoxy) silane; emulsifier: sorbitol anhydride 3.5 parts of oleic acid ester and alkylphenol polyoxyethylene ether-10 (mass ratio 5:2); initiator: 0.5 parts of azobisisoheptanonitrile; first solvent: 17.5 parts of ethyl acetate; second solvent: white Oil 15#90 parts.

[0045] Processing:

[0046] Step 1) Weigh the petroleum resin and the first solvent in a three-necked flask, and dissolve at 120°C for 1 hour;

[0047] Step 2) Continue to add emulsifier and mix for 35 minutes;

[0048] Step 3) At 105°C, pass nitrogen gas into the feed solution obtained in step 2) for 30 minutes, then add an initiator, dropwise add an organic acid and a crosslinking agent to obtain a mixed solution;

[0049] Step 4) Add the second solvent to the mixed solution obtained in step 3), stir and disperse at a high speed to obtain the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com