Gibbsite type high-iron bauxite source area impurity removal and quality improvement method

A high-iron bauxite and gibbsite-type technology, applied in cement production, grain processing, etc., can solve the problems of high impurities and low comprehensive utilization rate, and achieve low energy consumption, high comprehensive utilization rate and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

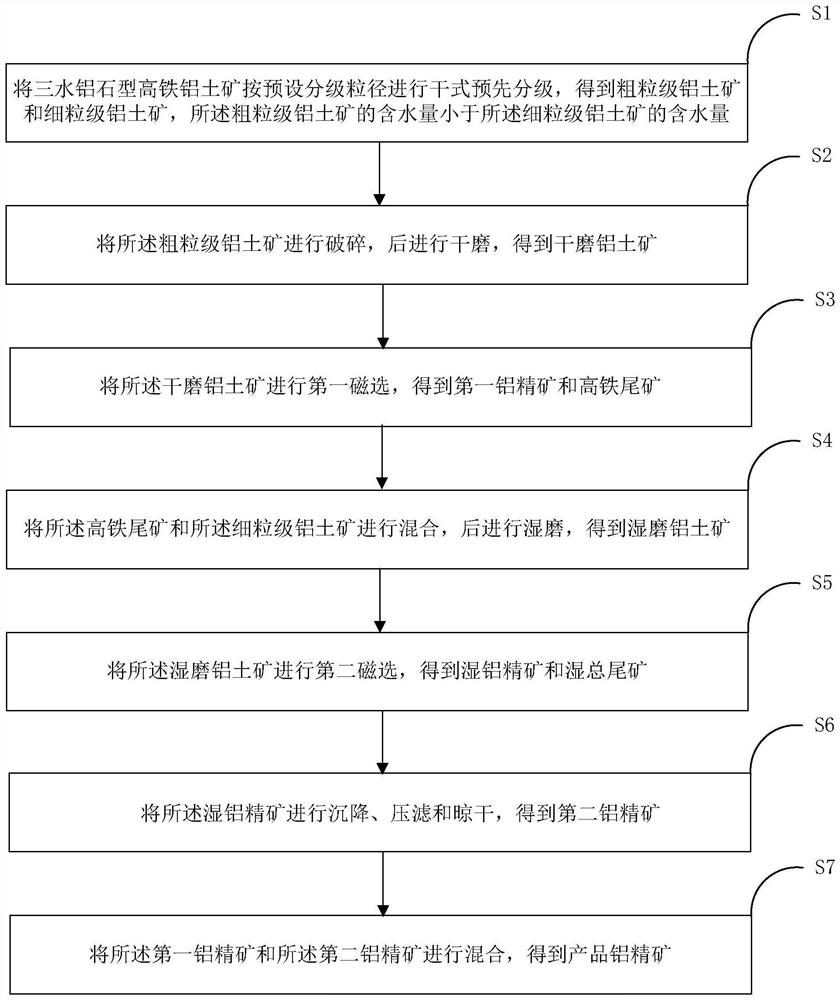

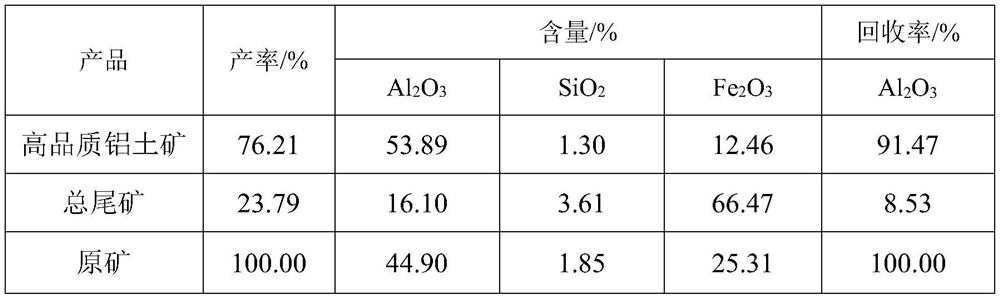

[0066] In this example, the Guinea three-water aluminum stone-type high-speed rail aluminum mine takes from the Boffa mining area, with a mass percentage, including Al 2 O 3 44.90%, SIO 2 1.85%, Fe 2 O 3 25.31%, useful minerals are three-water aluminum stone, and the pulse mineral is mainly aluminum needle iron ore, hematite, kaolinite, rutile, quartz, etc. According to the method of the present invention, the specific steps are as follows, and the specific steps are as follows. figure 1 :

[0067] Dry pre-classification of the rectangular mine in Guinea Boffa aluminum ore ore is obtained by 5 mm, resulting in crude grain-grade aluminum mine and high water-grained aluminum mines, and crude grain-grade aluminum ore jaw crusher And roller crusher is broken to 20 mm or less to perform dry mill (rod mill) to particle size -0.074 mm content of 73.52%, using CGDR dry electromagnetic double roller strong magnetic field magnetic exclusion machine (magnetic field strength) 1.8T) a sweep (m...

Embodiment 2

[0071] In this example, the Guinea three-water aluminum stone-type high-speed aluminum mine is taken from the Didia mining area, with a percentage of mass, including Al 2 O 3 42.45%, SIO 2 2.06%, Fe 2 O 3 28.95%, useful minerals are three-water aluminum stone, and the pulse mineral is mainly aluminum needle iron ore, hematite, kaolinite, rutile, quartz, etc. According to the method of the present invention, the specific steps are as follows, and the specific steps are as follows. figure 1 :

[0072] Use the roller screen and the drum screen to pre-grade the ore ore ore in the aluminum mines in 20 mm to obtain coarse grain-grade aluminum and high water-grained aluminum mines, and the coarse grain aluminum mine is used. The crusher and roller crusher are broken to 20 mm or less, then dry mill (rod mill) to particle size -0.074 mm, 70.43%, using CGR-54-type permanent magnet double roller strong magnetic field magnetic exchanger Perform a coarse (magnetic field strength 1.7T) a sweep ...

Embodiment 3

[0076] In this example, the Guinea three-water aluminum stone-type high-speed aluminum mine is taken from the Ribei mining area, with a percentage of mass, including Al 2 O 3 40.70%, SIO 2 1.52%, Fe 2 O 3 31.09%, useful minerals are three-water aluminum stone, and the pulse mineral is mainly aluminum needle iron ore, hematite, kaolinite, golden red, quartz, etc. The method of the present invention has a method of preventing hybridization and utilization of high-aluminum mines according to the present invention. figure 1 ,Specific steps are as follows:

[0077]The roller screen and the vibrating screen are used to pre-grade the ore ore in the aluminum mine mine in a crude grain-grade aluminum mine and high water-grained aluminum mine, and the crude grain-grade aluminum mine is obtained. The crusher and roller crusher are broken to 20 mm or less, and then dry mill (rod mill) to particle diameter of 66.43%, using CGR-54 dry permanent magnet double roller strong magnetic field magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com