Method for modifying dihydroxy-terminated polyphenyl ether

A technology of double-terminated hydroxyl polyphenylene ether and polyphenylene ether, which is applied in the field of polyphenylene ether modification, can solve the problems of low utilization rate of reactants, high cost of anhydride route, and difficulty in removing halogens, so as to improve electrophilic ability and avoid Halogen residues and the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

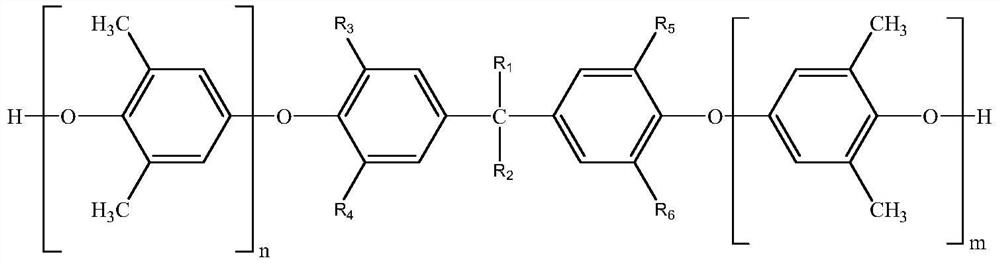

[0043] In the present invention, the preparation method of the double-terminated hydroxyl polyphenylene ether preferably includes the following steps:

[0044] Mix 2,6-dimethylphenol, dihydric phenol, organic solvent, catalyst and oxidant, and react at 20-70°C for 4-20 hours to obtain a polymerization liquid;

[0045] The polymerization solution and the chelating agent are mixed for chelation to obtain double-terminated hydroxyl polyphenylene ether;

[0046] The catalyst is an aqueous solution containing metal and amine ligands.

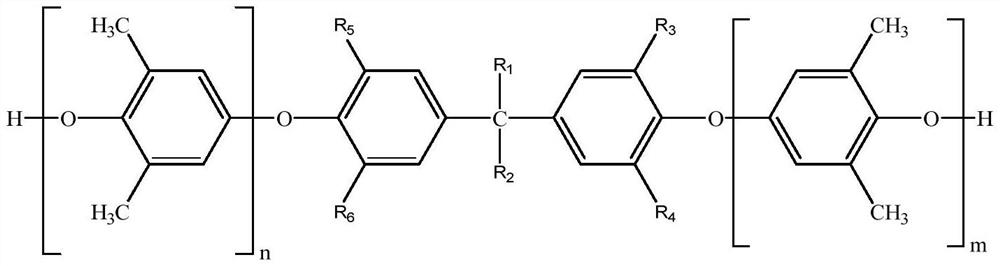

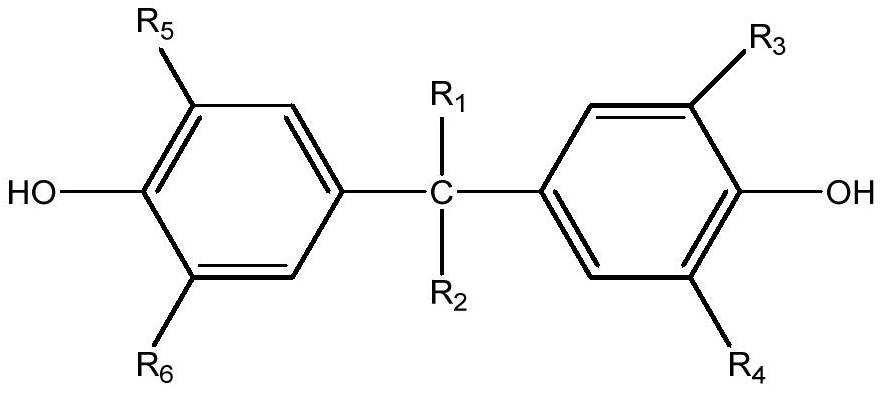

[0047] In the present invention, it is preferred to mix 2,6-dimethylphenol, dihydric phenol, organic solvent, catalyst and oxidant, and react at 20-70° C. for 4-20 hours to obtain a polymerization liquid. In the present invention, the molar ratio of 2,6-dimethylphenol to dihydric phenol is preferably 1˜15:1, more preferably 9:1. In the present invention, the dihydric phenol is preferably shown in structure (II):

[0048]

[0049] where R 1 , R...

Embodiment 1

[0058] (1) Add 0.598 kg of cuprous chloride and 0.702 kg of hexamethylenediamine to the catalyst preparation kettle, and add 0.6 kg of distilled water. After mixing evenly, stir for 1 hour under anaerobic conditions to obtain the catalyst. Add 53.5kg of 2,6-xylenol, 14kg of tetramethylbisphenol A and 250kg of toluene organic solvent in sequence, stir until the phenolic monomers are completely dissolved; then add the catalyst prepared above, then pass in oxygen, and react at 40°C 6h;

[0059] (2) After the reaction, add 35L 5%wt ethylenediaminetetraacetic acid disodium salt aqueous solution into the reaction kettle, stir at 70°C for 1h, then let it stand for 5h, remove the water phase, and obtain the double-terminated hydroxyl polyphenylene ether oligomer solution;

[0060] (3) After adding 260g DMAP (4-dimethylaminopyridine) to the solution of double-terminated hydroxyl polyphenylene ether oligomer obtained in step (2) and mixing evenly, after dissolving 3.01kg DCC (dicyclohe...

Embodiment 2

[0064] (1) Add 0.543kg of cuprous bromide and 0.757kg of dodecyl diamine to the catalyst preparation kettle, and add 0.7kg of distilled water, after mixing evenly, stir for 1 hour under anaerobic conditions to obtain the catalyst; Add 53.5kg of 2,6 dimethylphenol, 12.38kg of tetramethylbisphenol F and 238kg of toluene organic solvent, stir until the phenolic monomers are completely dissolved; then add the above catalyst, then pass in oxygen, and react at 40°C for 6 hours;

[0065] (2) After the reaction, add 70L 5%wt ethylenediaminetetraacetic acid disodium salt aqueous solution into the reaction kettle, stir at 50°C for 1h, then let it stand for 3h, remove the water phase, and obtain the double-terminated hydroxyl polyphenylene ether oligomer solution;

[0066] (3) Add 260g of DMAP to the purified double-terminated hydroxyl polyphenylene ether oligomer solution obtained in step (2) and mix evenly, then dissolve 3.01kg of DCC and drop it into the reactor, and add 10.46kg of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com