PN junction base coupled gallium nitride Schottky diode and production method thereof

A Gallium Nitride Schottky and base coupling technology, which is applied in the direction of diode, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems affecting the forward characteristics of the device, affecting the reliability of the device, reducing the device current, etc., to achieve Low cost, reduced electric field strength, improved breakdown voltage and reverse breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

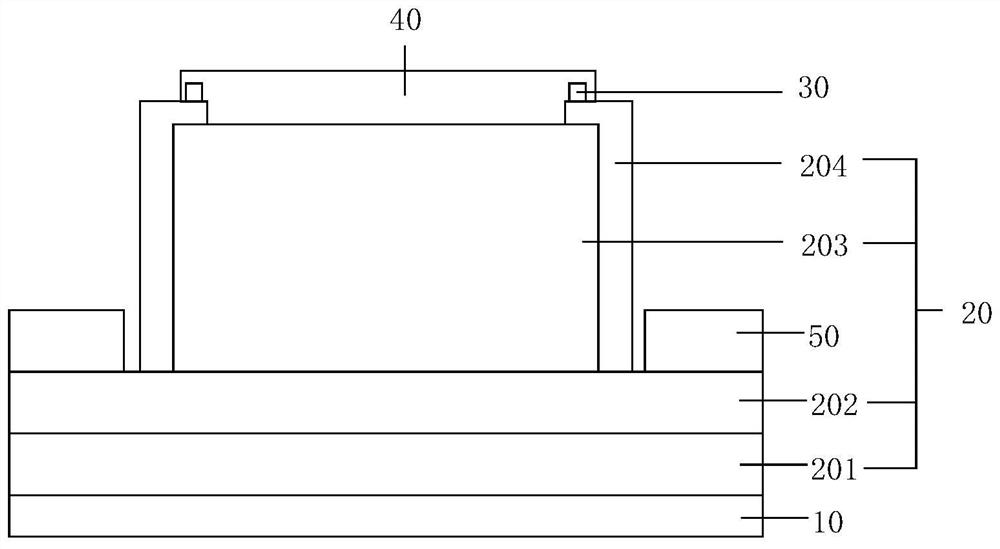

[0037] See figure 1 , figure 1 A schematic structural diagram of a gallium nitride Schottky diode coupled to a PN junction base provided by an embodiment of the present invention. The PN junction base-coupled GaN Schottky diode is a high-voltage Schottky diode, which includes a substrate layer 10 , an epitaxial layer 20 , an ohmic electrode 30 , an anode 40 and a cathode 50 .

[0038] Wherein, the epitaxial layer 20 is located on the substrate layer 10 . The epitaxial layer 20 is a Group-III nitride epitaxial layer, including a buffer layer 201, a contact layer 202, a drift layer 203, and a regrowth barrier layer 204. The buffer layer 201, the contact layer 202, and the drift layer 203 are stacked sequentially from bottom to top, and the regrowth potential The barrier layer 204 is arranged on the side surface and part of the upper surface of the drift layer 203, and a PN junction is formed between the regrowth barrier layer 204 and the drift layer 203; the ohmic electrode 30...

Embodiment 2

[0052] On the basis of Example 1, please refer to Figure 2a-Figure 2j , Figure 2a-Figure 2j It is a process schematic diagram of a method for manufacturing a PN junction base-coupled high-voltage gallium nitride Schottky diode provided by an embodiment of the present invention. The preparation method comprises steps:

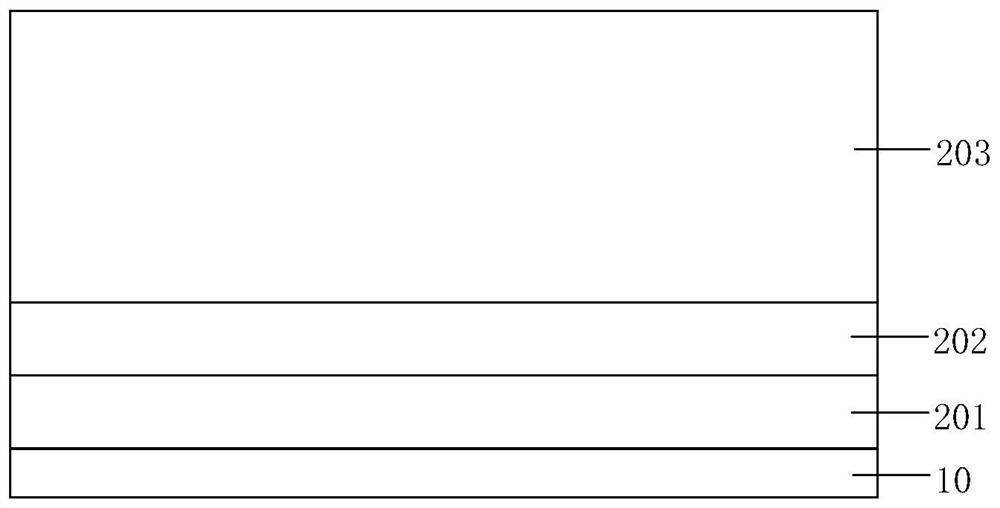

[0053] S1. Epitaxially grow the buffer layer 201, the contact layer 202 and the drift layer 203 on the substrate layer 10 in sequence, please refer to Figure 2a .

[0054] In this embodiment, the buffer layer 201 is an AlN / GaN superlattice buffer layer with a thickness of 750 nm; the contact layer 202 is a heavily doped N-type contact layer with a thickness of 1 μm and a doping concentration of 1× 10 19 cm -3 ; The drift layer 203 is a lightly doped N-type drift layer with a thickness of 2.2 μm and a doping concentration of 2×10 19 cm -3 .

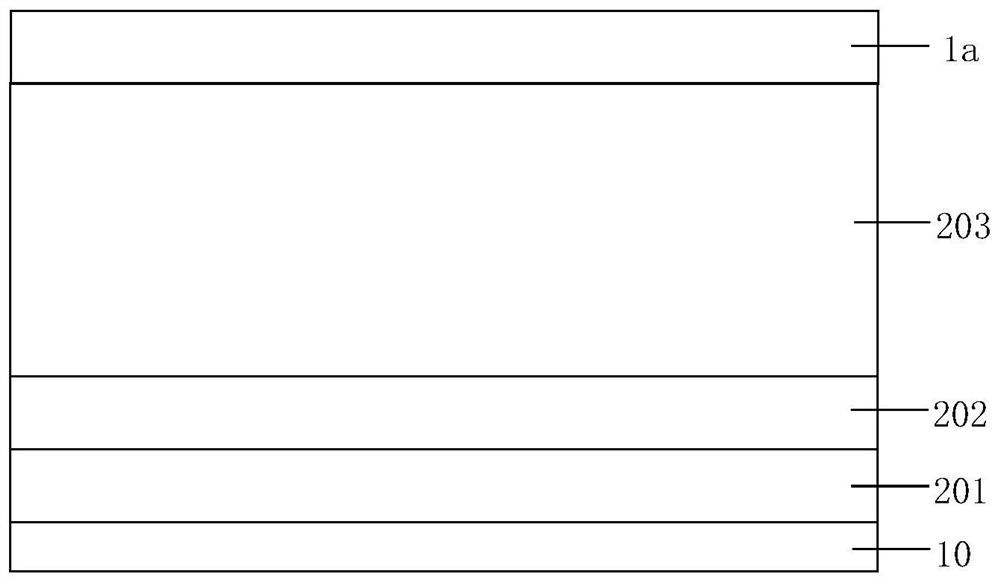

[0055] S2. Prepare a regrown barrier layer 204 on the side surface and part of the upper surface of the drift l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com