Foam separation method for beta-glucanase in fermentation liquor

A glucanase and foam separation technology, applied in the directions of microorganism-based methods, glycosylases, biochemical equipment and methods, etc., can solve the problems of difficult separation, product inhibition, low utilization rate of nutrients, etc. High resolution, reduced effect of denaturation, reduced effect of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

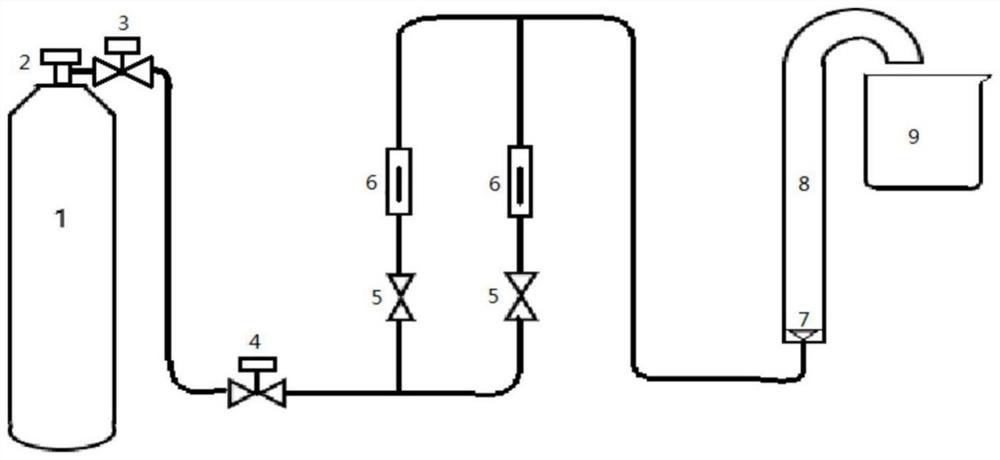

Method used

Image

Examples

Embodiment 1

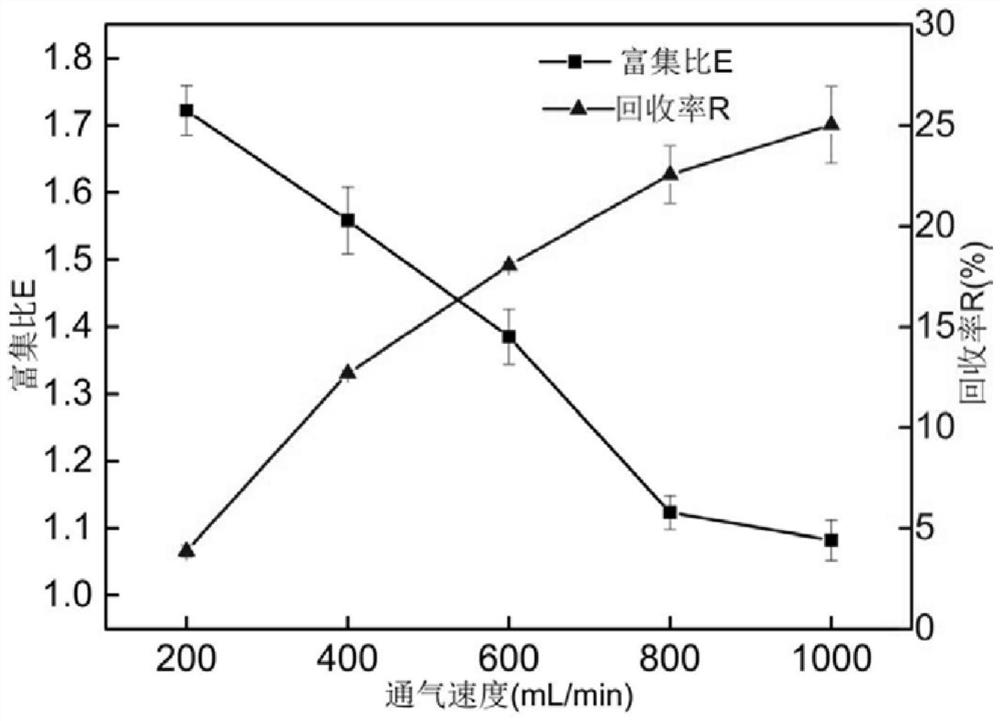

[0055] This example is to change the aeration rate in the fermentation broth, fix other experimental factors, compare the recovery rate and enrichment ratio of β-glucanase in the shake flask culture solution under different aeration rates, and determine the best separation and harvest of shake flask β - Aeration rate of dextranase.

[0056] Five groups of foam separation experiments were designed, the gradient of ventilation rate was 200mL / min, 200mL / min, 400mL / min, 600mL / min, 800mL / min, 1000mL / min were selected respectively, other conditions were determined as follows: liquid volume 100mL, initial enzyme The concentration is 100 μg / mL, the surfactant concentration is 0.4 mg / mL, the pH value of the solution is 6, and the collection time is 10 min. The result is as figure 2 shown.

[0057] According to the experimental results, the enrichment ratio E of β-glucanase decreases with the increase of the ventilation rate, and the enrichment ratio E has a maximum value of 1.69 whe...

Embodiment 2

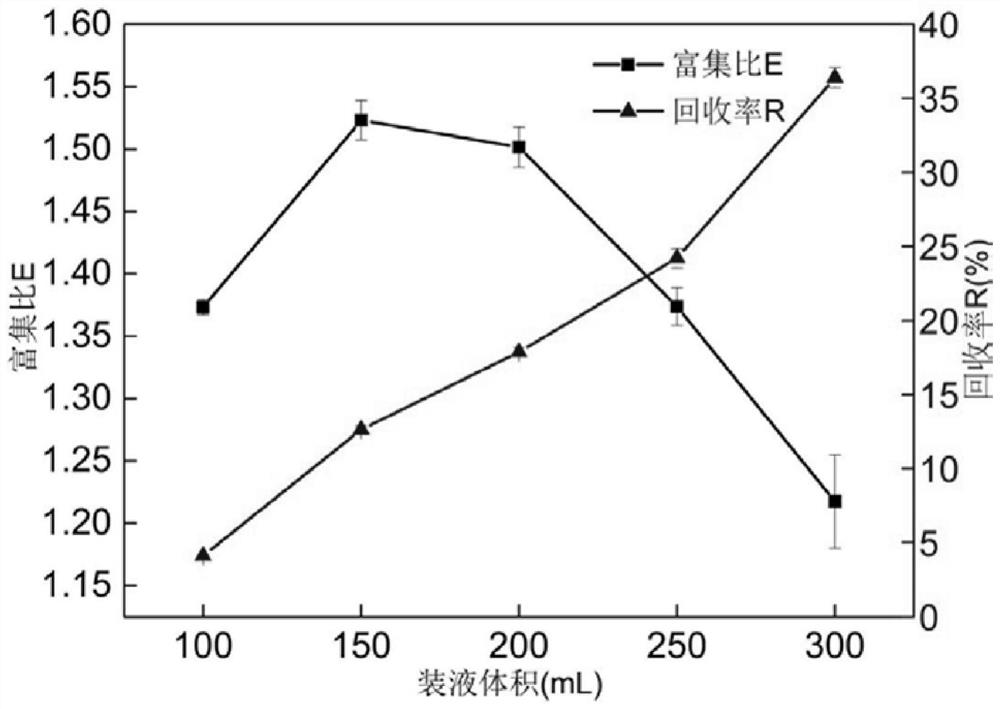

[0059] This example is to change the liquid volume in the foam separation system, fix other experimental factors, compare the recovery rate and enrichment ratio of β-glucanase in the shake flask culture solution under different liquid volumes, and determine the best separation and recovery Filling volume of shake flask β-glucanase.

[0060] Five groups of foam separation experiments were designed, and the filling volumes were 50mL, 150mL, 200mL, 250mL, and 300mL, and the other conditions were determined as follows: the ventilation rate was 400mL / min, the initial enzyme concentration was 100μg / mL, and the surfactant concentration was 0.4mg / mL , the pH of the solution was 6, and the collection time was 10 minutes. The result is as image 3 shown.

[0061] From the experimental results, the enzyme activity recovery rate R of β-glucanase increases with the increase of the filling volume, and has a maximum value of 35.76% when the filling volume is 300mL. The enrichment ratio E ...

Embodiment 3

[0063] This example is to change the initial enzyme concentration in the foam separation system, fix other experimental factors, compare the recovery rate and enrichment ratio of β-glucanase in the shake flask culture solution under different initial enzyme concentrations, and determine the best separation and recovery Initial enzyme concentration of shake flask β-glucanase.

[0064] Five groups of foam separation experiments were designed, the initial enzyme concentration gradient was 25 μg / mL, 50 μg / mL, 75 μg / mL, 100 μg / mL, 125 μg / mL, 150 μg / mL were selected respectively, other conditions were determined as follows: ventilation rate 400 mL / min, The filling volume is 100mL, the surfactant concentration is 0.4mg / mL, the pH value of the solution is 6, and the collection time is 10min. The result is as Figure 4 shown.

[0065] From the results, the enzyme activity recovery R of β-glucanase showed a trend of first increasing and then decreasing with the increase of the initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com