Double-sided aluminum substrate with embedded high-thermal-conductivity graphite flakes and manufacturing method of double-sided aluminum substrate

A technology of high thermal conductivity graphite and its production method, which is applied in the direction of circuit heating devices, printed circuit manufacturing, printed circuit components, etc., can solve the problems of difficult heat dissipation, failure to dissipate heat, failure, etc., and achieve good electrical and thermal conductivity, Good market application value and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

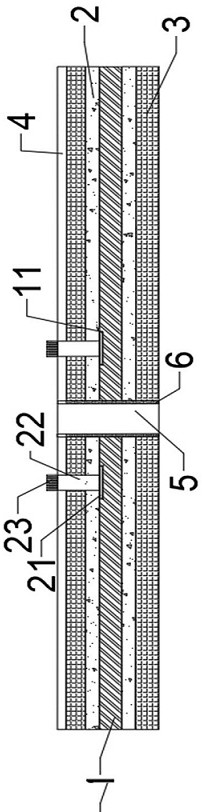

[0032] Embodiment 1: as figure 1 As shown, in order to solve the defect of difficult heat dissipation between multilayer boards in the prior art, the present invention provides a double-sided aluminum substrate 1 embedded with a high thermal conductivity graphite sheet 2, including an aluminum substrate 1, the aluminum substrate 1 Graphite sheets 2 are respectively arranged on the upper and lower sides, and a copper foil layer 3 is arranged on the outside of the graphite sheet 2, and an electroplated anti-corrosion layer 4 is arranged on the top of the copper foil layer 3. On the aluminum substrate 1, graphite sheet 2 and copper A through hole 5 is opened between the foil layers 3, and a metal conduction layer 6 is plated on the inner surface of the through hole 5; a plurality of grooves 11 are arranged on the surface of the aluminum substrate 1, and the inside of the groove 11 A heat-absorbing sheet 21 is provided, the lower side of the heat-absorbing sheet 21 is connected to...

Embodiment 2

[0035] Embodiment 2: The present invention also provides a method for manufacturing a double-sided aluminum substrate 1 embedded with a high thermal conductivity graphite sheet 2, comprising the following steps:

[0036] S1. Grooving: After the pure aluminum plate is cut, a groove 11 is opened on the surface of the aluminum substrate 1, and the heat absorbing sheet 21 is pressed into it;

[0037] S2. Grinding plate: rubbing and roughening the surface of the aluminum plate;

[0038] S3. Pressing: stacking the aluminum substrate 1, two layers of graphite sheet 2 and two layers of copper foil layer 3 sequentially and pressing them together;

[0039] S4. Drilling 1: Use the principle of concentric circles to design the drill belt, and drill out the pressed through holes 5, mounting holes, and fixing holes;

[0040] S5, immersion copper, electroplating: Metallize the through hole 5 through immersion copper and full board electroplating;

[0041] S6. Drilling 2: Confirm the coeffi...

Embodiment 3

[0044] Embodiment 3: In Embodiment 2, the following process is added. In step S1, a plurality of grooves 11 are opened on the double-sided aluminum substrate 1, a small amount of PP glue is filled in the grooves 11, and the heat absorbing sheet 21 is placed Into the groove 11, the PP glue is baked, and after the PP glue is cured, the heat-absorbing sheet 21 is fixed and pressed.

[0045] Grooving: After the pure aluminum plate is cut, a groove 11 is opened on the surface of the aluminum substrate 1, and the heat absorbing sheet 21 is pressed into it; grinding plate: the surface of the aluminum plate is roughened by friction; pressing: the aluminum substrate 1, two layers of graphite sheet 2 and two layers of copper foil layer 3 are stacked up and down in sequence and pressed together; Drilling 1: use the principle of concentric circles to design the drill belt, and drill out the pressed through hole 5, mounting hole, and fixing hole; sink copper, Electroplating: Metallize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com