Feed additive for improving growth performance and meat quality of pigs as well as preparation method and application of feed additive

A technology of feed additives and growth performance, applied to bacteria used in food preparation, molding or processing of animal feed, application, etc., can solve the problems of low quality and slow growth of livestock products, improve disease resistance, slow down oxidation Effects of stress and reducing diarrhea rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

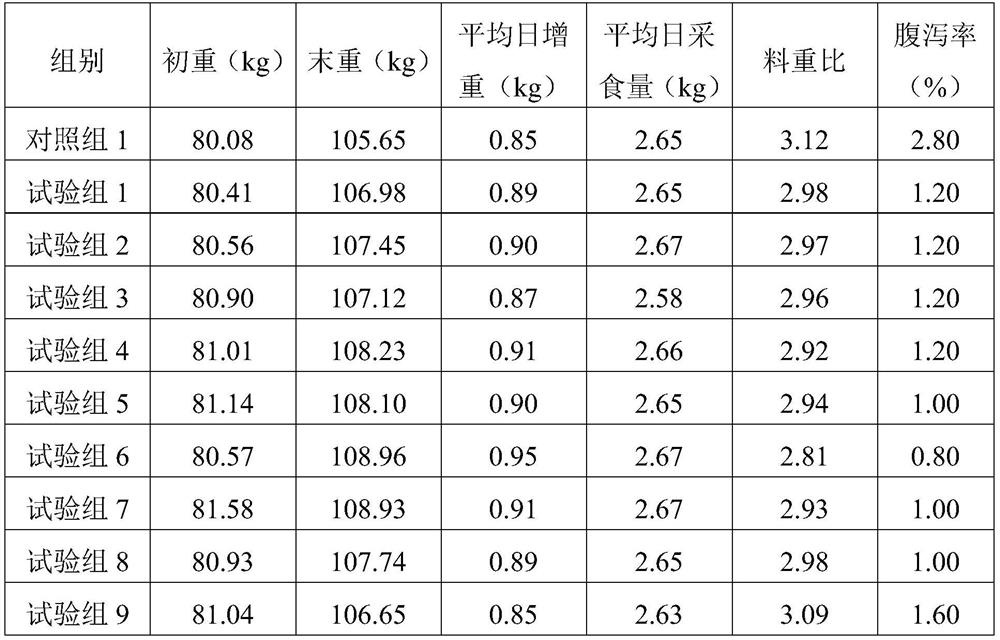

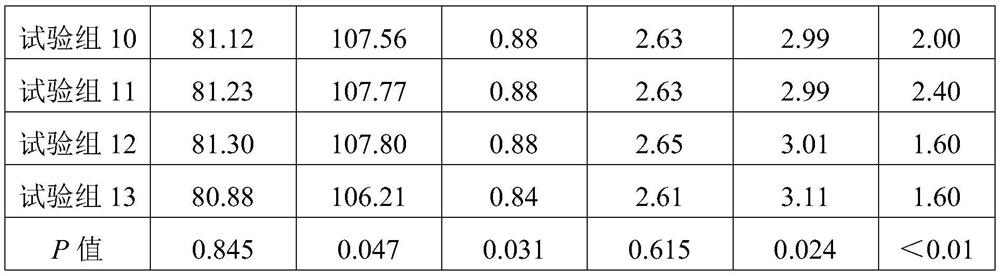

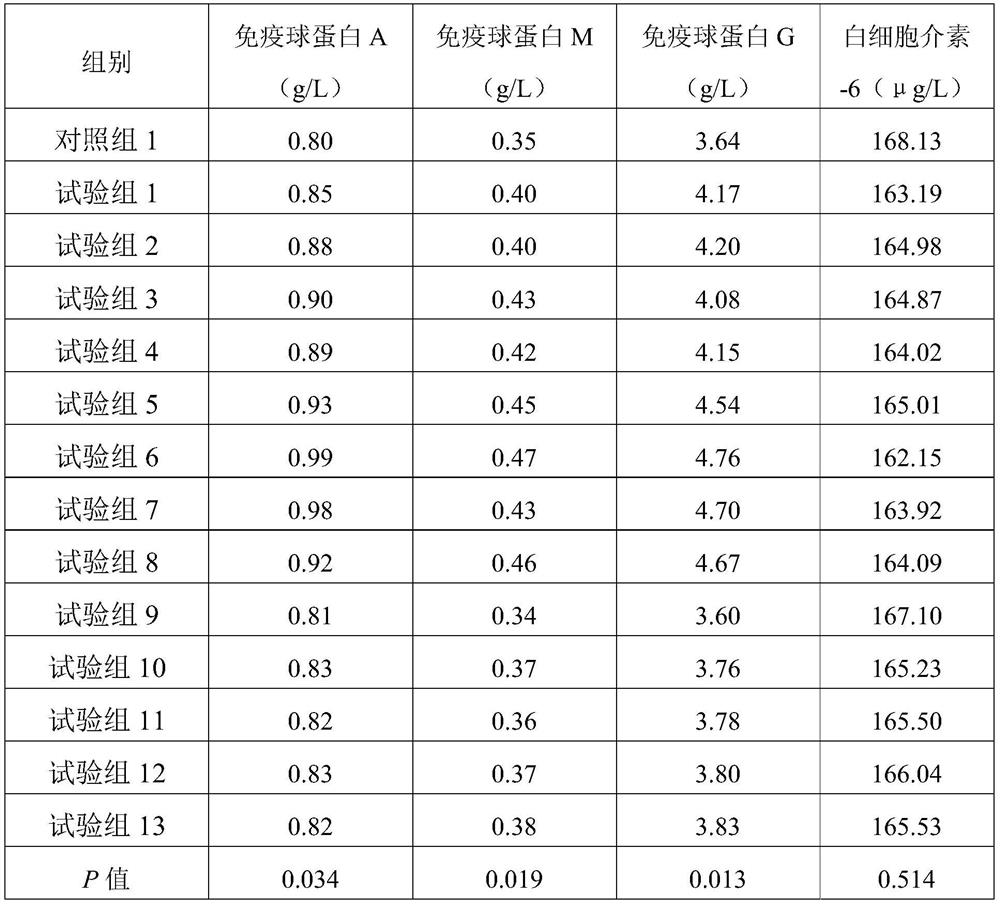

Examples

Embodiment 1

[0049] The present embodiment provides a kind of feed additive, and its preparation process is as follows:

[0050] Mix 8 parts by weight of prickly pear pomace and 8 parts by weight of honeysuckle to obtain the first mixed material.

[0051] 8.5 parts by weight of perilla oil and 36.5 parts by weight of puffed corn were mixed to obtain a second mixture.

[0052] Grind the above-mentioned first mixture into 200 mesh powder, and mix it with water whose weight is 1 times the weight of the above-mentioned first mixture under the condition of 22°C, Lactobacillus, Lactobacillus casei, Lactobacillus rhamnosus , saccharomycete and Aspergillus niger were mixed and fermented for 25 days in a mass ratio of 2:1:1:1, where the total mass content of Lactobacillus, Lactobacillus casei, Lactobacillus rhamnosus, saccharomyces and Aspergillus niger was 1%, Rosa roxburghii pomace 8wt%, honeysuckle 8wt%, water 16wt%, in addition, add 67wt% of wheat bran (making the sum of the mass percentages o...

Embodiment 2

[0055] The present embodiment provides a kind of feed additive, and its preparation process is as follows:

[0056] Mix 9 parts by weight of prickly pear pomace and 10 parts by weight of honeysuckle to obtain the first mixed material.

[0057] 9 parts by weight of perilla oil and 28 parts by weight of bran were mixed to obtain a second blend.

[0058] The above-mentioned first mixture was crushed to 250 mesh powder, and mixed with water whose weight was 0.5 times the weight of the above-mentioned first mixture under the condition of 23°C, and then wheat bran, Lactobacillus, Lactobacillus casei, Lactobacillus rhamnosus, saccharomyces and Aspergillus niger were fermented for 28 days in a mass ratio of 1:1:1:1. The total content of aspergillus is 1%, wheat bran is 70.5%, prickly pear residue is 9%, honeysuckle is 10%, and water is 9.5%. Then mix evenly with the second mixed material, 13 parts by weight of tea leaves, 10 parts by weight of P. japonica extract, 8 parts by weight ...

Embodiment 3

[0061] The present embodiment provides a kind of feed additive, and its preparation process is as follows:

[0062] Mix 10 parts by weight of prickly pear pomace and 11 parts by weight of honeysuckle to obtain the first mixed material.

[0063] 10.4 parts by weight of perilla oil and 20.6 parts by weight of bran were mixed to obtain a second blend.

[0064] Crush the above first mixture into 280-mesh powder, and mix it with water whose weight is 0.5 times the weight of the above first mixture at 25°C, then add wheat bran, Lactobacillus, Lactobacillus casei, Lactobacillus rhamnosus, saccharomyces and Aspergillus niger were fermented for 30 days in a mass ratio of 2:2:1:1. Here, by weight percentage, Lactobacillus, Lactobacillus casei, Lactobacillus rhamnosus, saccharomyces and The total content of aspergillus is 1%, wheat bran is 67.5%, prickly pear residue is 10%, honeysuckle is 11%, and water is 10.5%. Then mix with the second mixed material, 14.5 parts by weight of tea lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com