Porous ceramic, binder thereof, preparation methods of two and application of porous ceramic

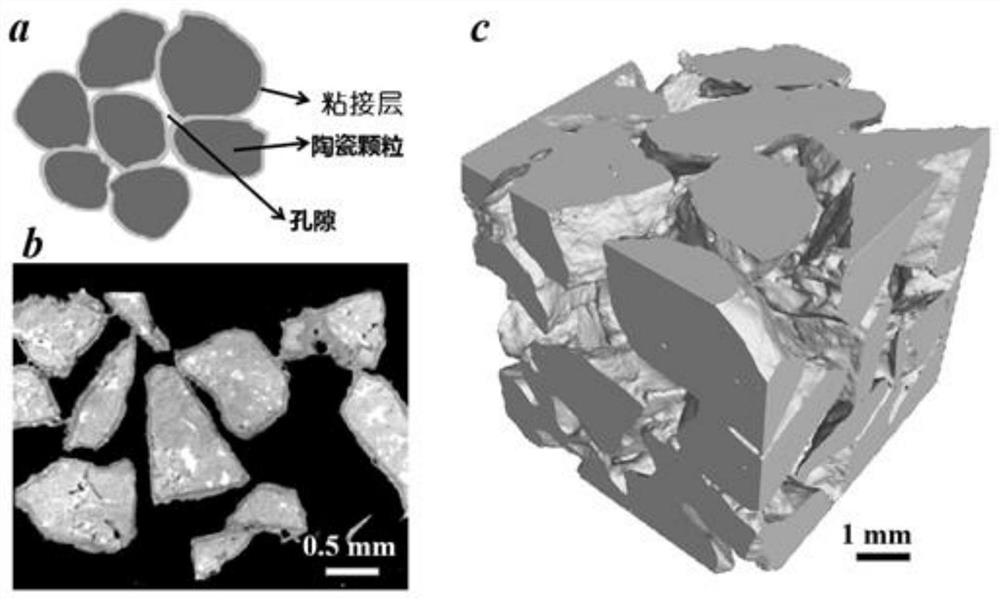

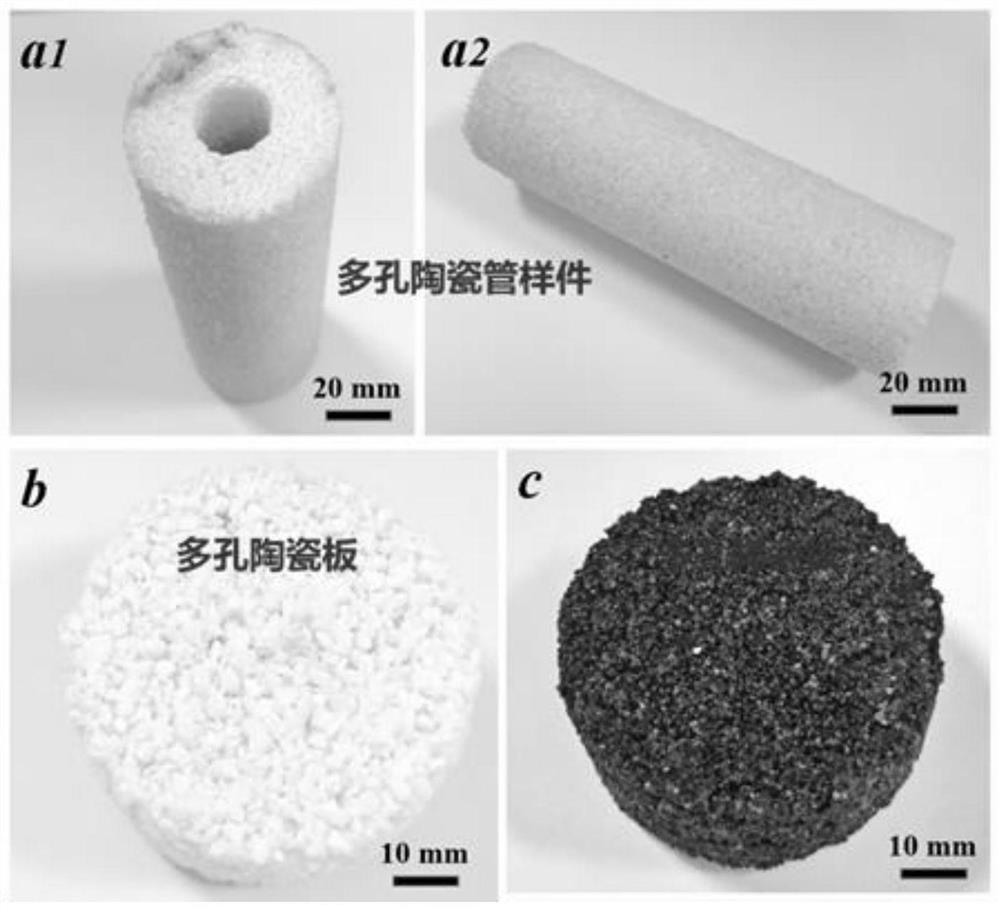

A technology for porous ceramics and binders, applied in the field of ceramic materials, can solve problems such as filter material damage, and achieve the effects of small pore size, good chemical stability, high-temperature mechanical properties, and a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the binder of the porous ceramic provided by the embodiment of the present application includes:

[0043] Calcining the reaction raw materials at 1200-1350°C for at least 5 minutes to obtain a binder, the components of the binder include: Al 2 o 3 : 5 to 50%, SiO 2 : 5~33%, alkaline earth metal oxide 2~50%, B 2 o 3 : 1 to 43%, the alkaline earth metal oxide is at least one or a mixture of two of CaO and MgO;

[0044] Al 2 o 3 , SiO 2 , alkaline earth metal oxides and B 2 o 3 The sum of the contents is at least 90.5%, and when there is a balance in the components, the balance includes impurities or reinforcing components. It should be noted that the balance refers to the Al in the composition 2 o 3 , SiO 2 , alkaline earth metal oxides and B 2 o 3 That part where the sum of the contents is less than 100%.

[0045] Al 2 o 3 and SiO 2 It is the main component of the adhesive and the main forming phase of the adhesive layer. Al 2...

Embodiment 1

[0083] This embodiment provides a method for preparing porous ceramics, and the ceramic particles are made of 12-mesh white corundum. The content of alumina in white corundum is more than 99%. The chemical composition of the binder is: SiO 2 : 22%, CaO: 10%, MgO: 24%, B 2 o 3 : 22%, TiO 2 : 1.8%, Na 2 O: 0.5%, ZnO: 0.5%, the balance is Al 2 o 3 . The purity of each raw material is close to 100%.

[0084] Step S1, preparation of binder

[0085] Mix the reaction raw materials thoroughly and evenly according to the components of the above-mentioned binder. Put the mixed raw materials into a high-temperature furnace for calcination. The calcination temperature is 1250° C. for 10 minutes. The raw materials are partially melted and interdiffused to form lumps. The reactant is crushed and ground into powder by a crushing powder machine, and the powder passes through a 200-mesh sieve to obtain adhesive powder for the next step.

[0086] Step S2, mixing

[0087] Water glass...

Embodiment 2

[0092] This embodiment provides a preparation method of porous ceramics. The ceramic particles are made of 4-mesh brown corundum. The content of alumina in brown corundum is more than 95%. The chemical composition of the binder includes by weight percentage: SiO 2 : 20%, CaO: 10%, MgO: 25%, B 2 o 3 : 28%, TiO 2 : 1.0%, Na 2 O: 0.4%, ZnO: 0.6%, the balance is Al 2 o 3 . The purity of each raw material is close to 100%.

[0093] Step S1, preparation of binder

[0094] Thoroughly mix the above binder raw materials evenly. The mixed raw materials are put into a high-temperature furnace for calcination. The calcination temperature is 1350° C. for 9 minutes. The raw materials are partially melted and interdiffused to agglomerate. Use a crushing powder machine to crush and grind the binder into powder, and the powder passes through a 200-mesh sieve to obtain binder powder for the next step.

[0095] Step S2, mixing

[0096] Use water glass as the adhesive, and the modulu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com