Ti2AlNb-based alloy for casting, preparation method of Ti2AlNb-based alloy and casting

A technology of base alloy and ingot, applied in the field of Ti2AlNb base alloy for casting and its preparation, can solve the problems of coarse grain, poor plasticity, difficulty in filling and completeness, etc., and achieve the effect of good strength, plasticity and excellent casting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In some embodiments of the present invention, the above-mentioned Ti for casting is also provided 2 A method for preparing an AlNb-based alloy, comprising the steps of:

[0046] (A) After proportioning the ingredients, Ti was prepared by suspension smelting 2 AlNb-based alloy ingot;

[0047] (B) put Ti 2 AlNb-based alloy ingots were remelted and poured into molds, and Ti was obtained for casting after hot isostatic pressing and heat treatment. 2 AlNb-based alloys.

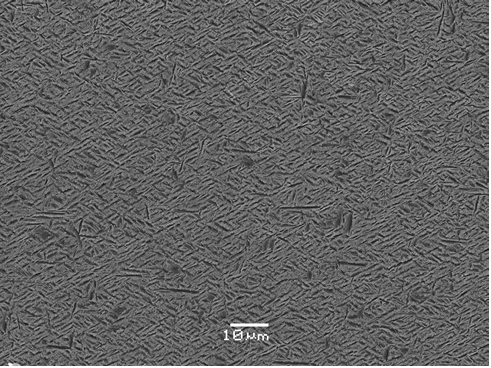

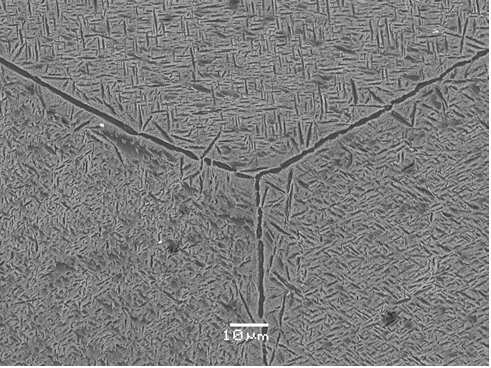

[0048] The present invention adopts specific composition and proportioning Ti for casting 2 AlNb-based alloy ingredients, after smelting, hot isostatic pressing and heat treatment steps, can produce Ti with higher strength and plasticity 2 AlNb-based alloys; Ti for this casting 2 The grain size of the AlNb-based alloy is less than 300 μm, and the microstructure is a continuous B2 matrix with normally distributed O-phase laths. The average size of the O-phase laths is about 4 μm, and the O-phase volume ...

Embodiment 1

[0057] This embodiment provides Ti for casting 2 Preparation of AlNb-based alloys, the obtained Ti for casting 2 The composition of the AlNb-based alloy is shown in Table 1.

[0058] Table 1

[0059] Alloy No. Alloy composition-mass percentage (%) 1# Al 10.9%, Nb 42.6%, Si 0.10%, balance Ti 2# Al 10.9%, Nb 42.6%, Si 0.05%, balance Ti 3# Al 10.9%, Nb 42.6%, Si 0.15%, balance Ti

[0060] Specifically, the above casting Ti 2 The preparation method of AlNb-based alloy comprises the following steps:

[0061] Put the prepared sponge titanium, pure niobium chips, aluminum beans, AlSi master alloy, etc. into the water-cooled copper crucible of the suspension furnace, in which the AlSi master alloy is wrapped with aluminum foil and placed in the middle of the height of the copper crucible, and then vacuumized to prepare for melting ;When the vacuum degree is ≤3Pa, fill it with argon to 5000Pa for inert atmosphere protection; start from 200kW, melt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com