Electrochemical sensor for in-situ analysis and detection of heavy metal copper ions in soil solution

A soil solution and sensor technology, applied in the field of electrochemical analysis and detection, can solve the problems of sensor interference, electrochemical sensor construction process, complex detection mechanism, complex composition, etc., and achieve high sensitivity and accuracy, stability and anti-interference ability Strong, easy-to-build effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Synthesis and characterization of Fe-MIL-101

[0048] Take 0.8105g FeCl 3 ·6H 2 O, 0.4985g terephthalic acid were dissolved in 40mL N,N-dimethylformamide (DMF) respectively, and then the terephthalic acid mixed solution was added dropwise to FeCl 3 ·6H 2 O mixed solution, stirred for 30 minutes until the mixture is uniform, then added 3.6mL of acetic acid, continued to stir until uniform, transferred to a high-temperature and high-pressure reactor, reacted at 110°C for 24h, then centrifuged until the supernatant was clear, stirred in ethanol at 60°C for 3h, and used Centrifuge with absolute ethanol until the supernatant is clear, continue to centrifuge with ultrapure water, and dry in vacuum at 60°C for 8 hours to obtain Fe-MIL-101.

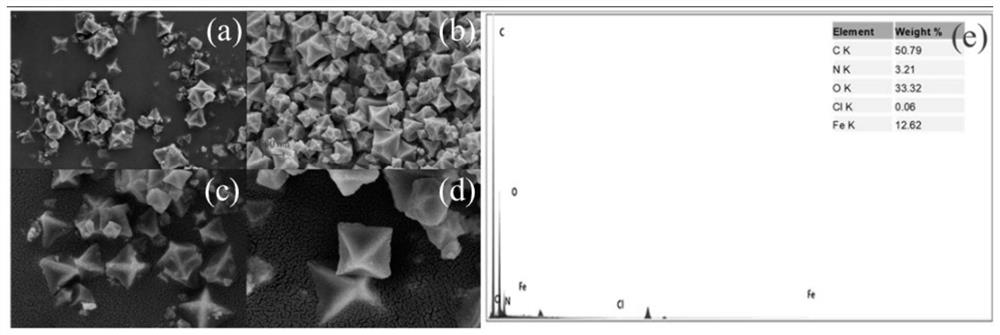

[0049] The obtained Fe-MIL-101 sample was scanned by electron microscope, as figure 1 As shown, under 500nm ( figure 1 b) It can be seen that Fe-MIL-101 is evenly distributed and has a uniform shape. at 200nm ( figure ...

Embodiment 2

[0052] Example 2: Construction of an electrochemical sensor for in-situ analysis and detection of heavy metal copper ions in soil solution

[0053] 1. Construction of the working electrode

[0054] With the glassy carbon electrode as the substrate, after grinding, soaking (the volume ratio of concentrated sulfuric acid and hydrogen peroxide is 3:1), and ultrasonic cleaning, it was inserted into 0.5M H 2 SO 4 In the solution, cyclic voltammetry scanning activation was carried out in the range of -0.4 to 0.8V at 50mV / s to reach a steady state. Place the electrode in 0.1M KCl and 5.0mM Fe(CN) 6 3- In the solution (the solvent is 0.1M PBS buffer solution, pH 7.4), measure the peak potential difference to ensure that it is within 120mV, and then proceed to subsequent electrode construction.

[0055] Add the Fe-MIL-101 material prepared in Example 1 into N,N-dimethylformamide, and sonicate for 1 h to obtain a Fe-MIL-101 material suspension with a concentration of 1.0 mg / mL. 5.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com