Rubber-like shape memory recyclable esophageal stent and preparation method thereof

A technology of memory and rubber, which is applied in the field of medical devices, can solve the problems of stenosis in the body, limit the clinical application of implanted stents in the body, and use restrictions, and achieve good biocompatibility, reduce medical burden, and less tissue stimulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The second object of the present invention is to provide a method for preparing the above-mentioned recyclable esophageal stent with rubber-like shape memory, comprising the following steps:

[0050] (1) heating the superelastic material and the shape memory polymer material to melt to obtain the first mixture;

[0051] (2) adding the first mixture obtained in step (1) to an organic solvent and biocompatible nanopowder, and mixing uniformly to obtain a second mixture;

[0052] (3) placing the second mixture obtained in step (2) in a star-shaped mold, and pressurizing it after processing to prepare a star-shaped stent;

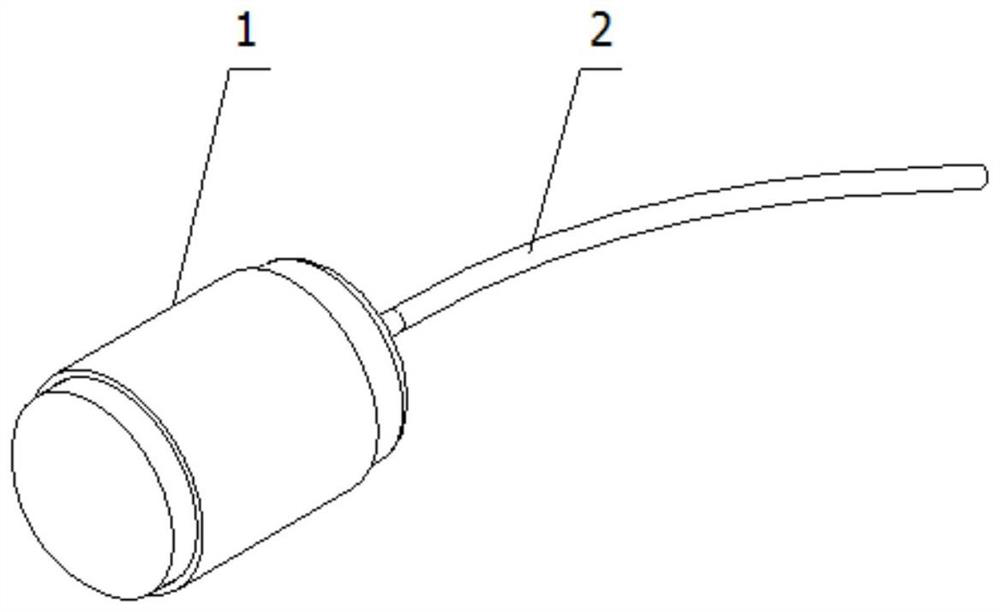

[0053] (4) expanding the star-shaped stent obtained in step (3) into a tubular shape by means of balloon inflation, and obtaining a rubber-like shape memory retrievable esophageal stent after sterilization.

[0054] In one embodiment of the present invention, in step (2), the mixture is homogeneously oscillated by an ultrasonic oscillator, and the organ...

Embodiment 1

[0068] This embodiment provides a recyclable esophageal stent with rubber-like shape memory.

[0069] Take 75 parts by weight of silicone rubber and 20 parts by weight of polyurethane (the glass transition temperature of polyurethane, that is, the recovery temperature of shape memory is 41° C.), and heat to melt.

[0070] Pour the melted mixture into a beaker filled with ethanol, and add 5 parts by weight of magnetic Fe 3 o 4 nano powder.

[0071] After the beaker was placed in an ultrasonic oscillator for 2 hours of ultrasonic vibration, the ethanol was volatilized by heating.

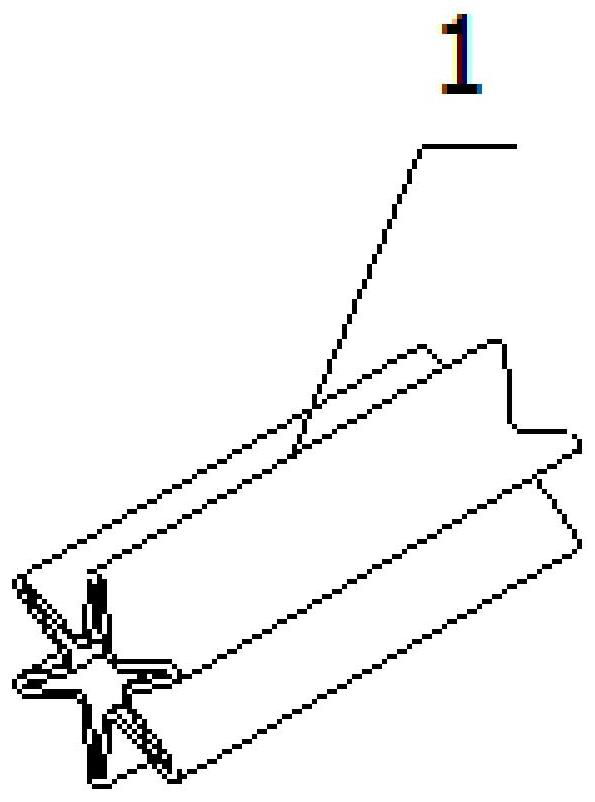

[0072] Make a star-shaped mold, pour the above mixture into the mold, heat it to 80°C to make it solidify and shape, and make the Fe-containing 3 o 4 Star-shaped scaffolds for nanopowders, such as figure 1 shown;

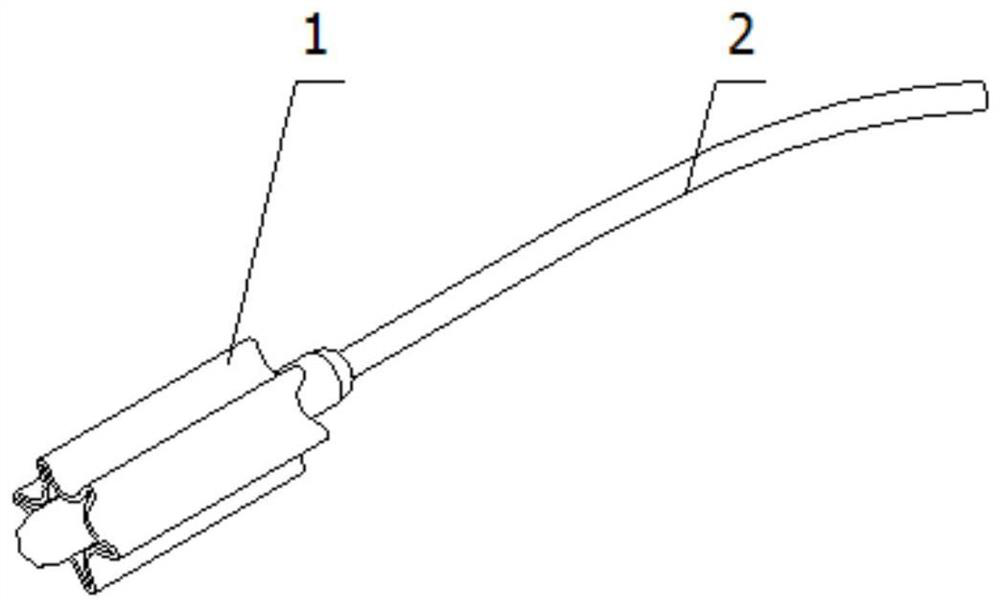

[0073] At a temperature higher than the glass transition temperature of polyurethane by 15°C (ie 56°C), through balloon inflation (such as figure 2 Shown) to contain Fe 3 o 4 The ...

Embodiment 2

[0076] This embodiment provides a recyclable esophageal stent with rubber-like shape memory.

[0077] Take 70 parts by weight of silicone rubber and 13 parts by weight of polyurethane (the glass transition temperature of polyurethane, that is, the recovery temperature of shape memory is 41° C.), and heat to melt.

[0078] Pour the melted mixture into a beaker filled with ethanol, and add 2 wt. parts of magnetic Fe to it 3 o 4 nano powder.

[0079] After the beaker was placed in an ultrasonic oscillator for 2 hours of ultrasonic vibration, the ethanol was volatilized by heating.

[0080] Make a star-shaped mold, pour the above mixture into the mold, heat it to 80°C to make it solidify and shape, and make the Fe-containing 3 o 4 Star-shaped scaffolds for nanopowders, such as figure 1 shown;

[0081] At a temperature higher than the glass transition temperature of polyurethane by 15°C (ie 56°C), through balloon inflation (such as figure 2 Shown) to contain Fe 3 o 4 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com