Castor oil-based hydroxyl acrylate emulsion as well as preparation method and application thereof

A technology of oil-based hydroxy acrylate and methyl methacrylate, applied in the field of castor oil-based hydroxy acrylate emulsion and its preparation, can solve the problems of poor water resistance, inability to 2K water-based polyurethane, low carbon-carbon double bond reactivity, and the like, Achieve the effects of good emulsion stability, high strength and excellent film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

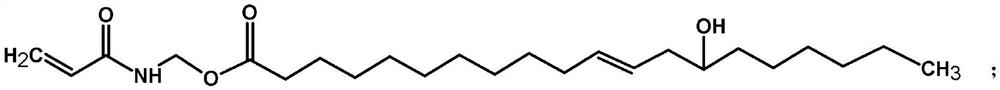

[0039] Preparation of castor oil-based vinyl monomer:

[0040] Add 95.8g N,N-hydroxyethylacrylamide, 300g castor oil, 240g tetrahydrofuran, 2g sodium hydroxide powder and 0.2g 2,6-dimethylphenol into a 500ml four-necked flask, assemble a spherical condenser, After the argon gas inlet, mechanical stirrer and dropping funnel, the flask was placed in a constant temperature water bath at 40°C for 4 hours and stirred continuously at a speed of 350r / min.

[0041] (2) The reaction liquid was cooled to room temperature, and 240 g of dichloromethane was added to the obtained clear liquid for dilution, and then 312 g of saturated saline was added to wash the mixed liquid, and by-products in the mixed liquid were removed by extraction to obtain a supernatant liquid.

[0042] (3) Add an excessive amount of anhydrous magnesium sulfate to the supernatant to remove moisture in the supernatant. After the anhydrous magnesium sulfate was removed by filtration, the remaining clear liquid was pl...

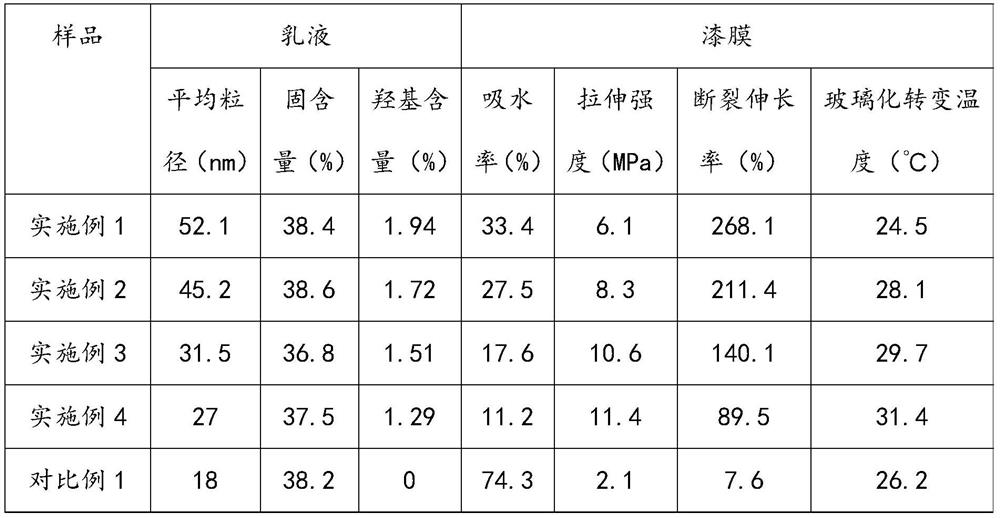

Embodiment 2

[0059] Preparation of castor oil-based vinyl monomer:

[0060] The castor oil-based vinyl monomer prepared in Example 1 was used.

[0061] Preparation of castor oil-based hydroxyacrylate emulsion:

[0062] (1) Add 40g castor oil vinyl monomer, 53g methyl methacrylate, 5g butyl acrylate, 2g acrylic acid, 0.4g sodium bicarbonate, 3g SDS, 0.8g APS and 60g water in a 500ml four-necked flask, Equipped with a mechanical stirrer, stirred at 350r / min for 30min to obtain a pre-emulsion.

[0063] (2) In another 500ml four-necked flask, add 1.5g SDS, 60g water, 0.2g sodium bicarbonate and 10g pre-emulsion and mix, after assembling spherical condenser, nitrogen inlet, mechanical stirrer and dropping funnel, put The flask was placed in a constant temperature water bath at 80°C and stirred continuously at a speed of 500r / min. The mixture of 0.4g APS and 15g water was continuously added dropwise to the mixed solution through the dropping funnel to carry out the first stage of emulsion pol...

Embodiment 3

[0070] Preparation of castor oil-based vinyl monomer:

[0071] The castor oil-based vinyl monomer prepared in Example 1 was used.

[0072] Preparation of castor oil-based hydroxyacrylate emulsion:

[0073] (1) Add 35g castor oil vinyl monomer, 53g methyl methacrylate, 10g butyl acrylate, 2g acrylic acid, 0.4g sodium bicarbonate, 3g SDS, 0.8g APS and 60g water in a 500ml four-necked flask, Equipped with a mechanical stirrer, stirred at 350r / min for 30min to obtain a pre-emulsion.

[0074] (2) In another 500ml four-necked flask, add 1.5g SDS, 60g water, 0.2g sodium bicarbonate and 10g pre-emulsion and mix, after assembling spherical condenser, nitrogen inlet, mechanical stirrer and dropping funnel, put The flask was placed in a constant temperature water bath at 80°C and stirred continuously at a speed of 500r / min. The mixture of 0.4g APS and 15g water was continuously added dropwise to the mixed solution through the dropping funnel to carry out the first stage of emulsion po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com