Layering temperature and ablation amount synchronous measurement method and device, and application

A technology of synchronous measurement and measurement method, applied in the field of measurement, can solve problems such as poor integration, thermal design error, measurement result error, etc., to achieve the effect of ensuring reliability, high integration, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

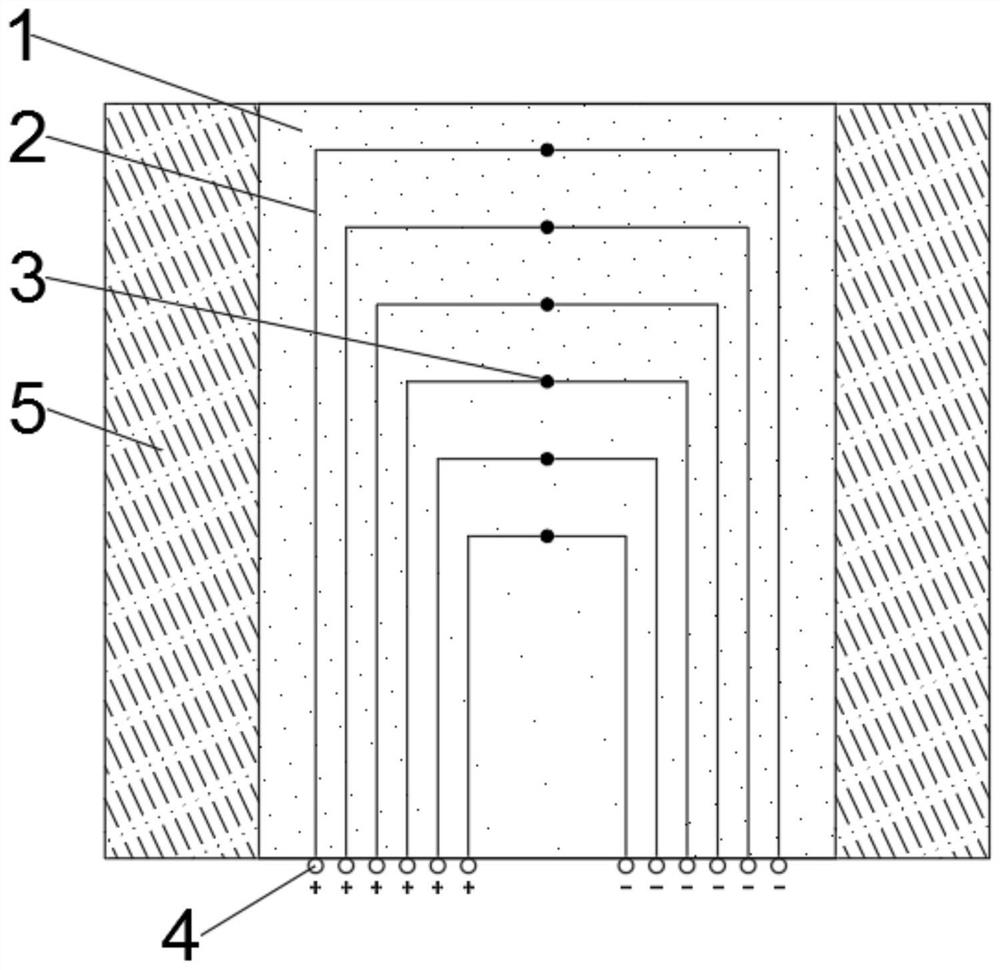

Embodiment 1

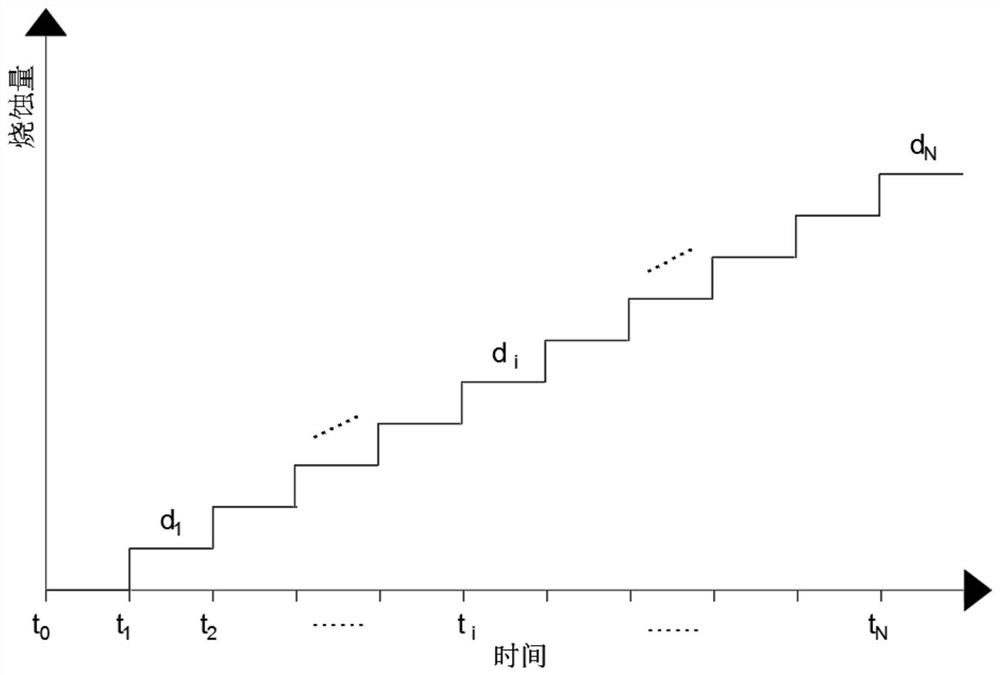

[0053] The present invention provides a synchronous measuring device for delamination temperature and ablation amount, which includes a substrate 1, which is installed in the opening of the heat-proof layer 5 by bonding, the top outer surface of the substrate 1 and the heat-proof layer 5 flush with the top surface. The heat-proof layer 5 is made of quartz phenolic material, and the substrate 1 is made of porous quartz ceramic material. By adjusting the porosity and doping components of the quartz ceramic, the substrate 1 has the same or similar thermal diffusivity and ablation resistance as the heat-proof layer 5, Temperature-sensitive elements 3 are arranged at different height positions of the substrate 1. The temperature-sensitive elements 3 are thermocouples composed of platinum-rhodium 10 and platinum, wherein the positive pole is platinum-rhodium 10, and the negative pole is platinum. The method of ion implantation and magnetron sputtering is adopted. The wire 2 made of ...

Embodiment 2

[0066] Specifically with embodiment 1, the difference is only in:

[0067] The shape of the base body 1 is a circular column. The base body 1 is installed in the opening of the heat-proof layer 5 through mechanical assembly. The temperature-sensitive elements 3 are arranged at different heights of the base body 1. The temperature-sensitive elements 3 are selected from temperature-sensitive resistors. The laser etching method is used to slot the substrate 1, the temperature sensitive resistor made of Pt100 is selected, and the temperature sensitive resistor and the wire are sintered and adhered to the substrate 1 in the slot corresponding to the substrate 1 by high-temperature sintering method, and the temperature-sensitive resistors at N positions, thereby forming N temperature-sensitive resistors distributed with high precision.

[0068] The wire 2 is connected with an external measurement circuit 4, and the surface of the temperature sensitive resistor and the wire 2 is coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com