Negative electrode piece, preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and negative pole pieces, which is applied in the direction of negative electrodes, electrode manufacturing, and secondary batteries. It can solve problems such as large polarization, attenuation of lithium analysis capacity, and capacity limitations of lithium cobalt oxide materials, so as to reduce polarization. , Improve the overpotential, improve the effect of lithium precipitation and capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

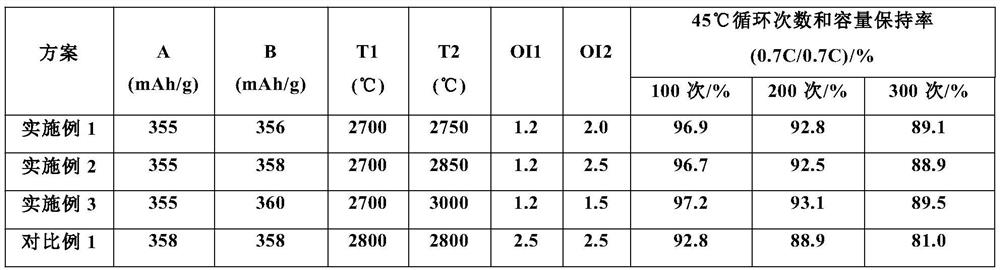

Embodiment 1

[0028] Artificial graphite, conductive carbon black, sodium carboxymethyl cellulose, styrene-butadiene rubber obtain the first negative electrode slurry that the gram capacity of artificial graphite is 355mAh / g by the mass percentage proportioning of 97.0%:0.5%:1.2%:1.3%, The graphitization temperature T1 of artificial graphite is 2700°C, and the OI value of artificial graphite is OI1=1.2. The first negative electrode slurry is coated on the long pasted surface of the carbon-coated copper foil of the negative electrode current collector to form a first negative electrode slurry with a thickness of 60um. Active coating; artificial graphite, conductive carbon black, sodium carboxymethyl cellulose, and styrene-butadiene rubber are obtained by the mass percentage ratio of 97.0%: 0.5%: 1.2%: 1.3%. The gram capacity of artificial graphite is 356mAh / g. Negative electrode slurry, the graphitization temperature T2 of artificial graphite is 2750 ℃, and the OI value of artificial graphite...

Embodiment 2

[0030] Artificial graphite, conductive carbon black, sodium carboxymethyl cellulose, styrene-butadiene rubber obtain the first negative electrode slurry that the gram capacity of artificial graphite is 355mAh / g by the mass percentage proportioning of 97.0%:0.5%:1.2%:1.3%, The graphitization temperature T1 of artificial graphite is 2700°C, and the OI value of artificial graphite is OI1=1.2. The first negative electrode slurry is coated on the long pasted surface of the carbon-coated copper foil of the negative electrode current collector to form a first negative electrode slurry with a thickness of 60um. Active coating; artificial graphite, conductive carbon black, sodium carboxymethyl cellulose, and styrene-butadiene rubber are obtained by the mass percentage ratio of 97.0%: 0.5%: 1.2%: 1.3%. The gram capacity of artificial graphite is 358mAh / g. Negative electrode slurry, the graphitization temperature T2 of artificial graphite is 2850 ℃, and the OI value of artificial graphite...

Embodiment 3

[0032]Artificial graphite, conductive carbon black, sodium carboxymethyl cellulose, styrene-butadiene rubber obtain the first negative electrode slurry that the gram capacity of artificial graphite is 355mAh / g by the mass percentage proportioning of 97.0%:0.5%:1.2%:1.3%, The graphitization temperature T1 of artificial graphite is 2700°C, and the OI value of artificial graphite is OI1=1.2. The first negative electrode slurry is coated on the long pasted surface of the carbon-coated copper foil of the negative electrode current collector to form a first negative electrode slurry with a thickness of 60um. Active coating; artificial graphite, conductive carbon black, sodium carboxymethyl cellulose, and styrene-butadiene rubber are obtained by the mass percentage ratio of 97.0%: 0.5%: 1.2%: 1.3%. The gram capacity of artificial graphite is 360mAh / g. Negative electrode slurry, the graphitization temperature T2 of artificial graphite is 3000 ℃, and the OI value of artificial graphite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com