LLTO/nanosheet lithium cobalt oxide composite positive electrode material and preparation method thereof

A composite positive electrode material, flake lithium cobalt oxide technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of poor battery performance, limited application, reduced capacity, etc., to improve power characteristics and safety Effect of enhancing and suppressing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

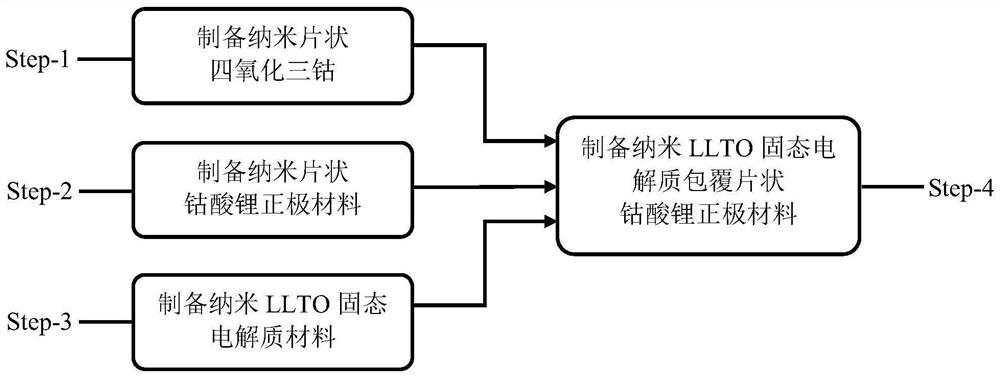

Method used

Image

Examples

Embodiment 1

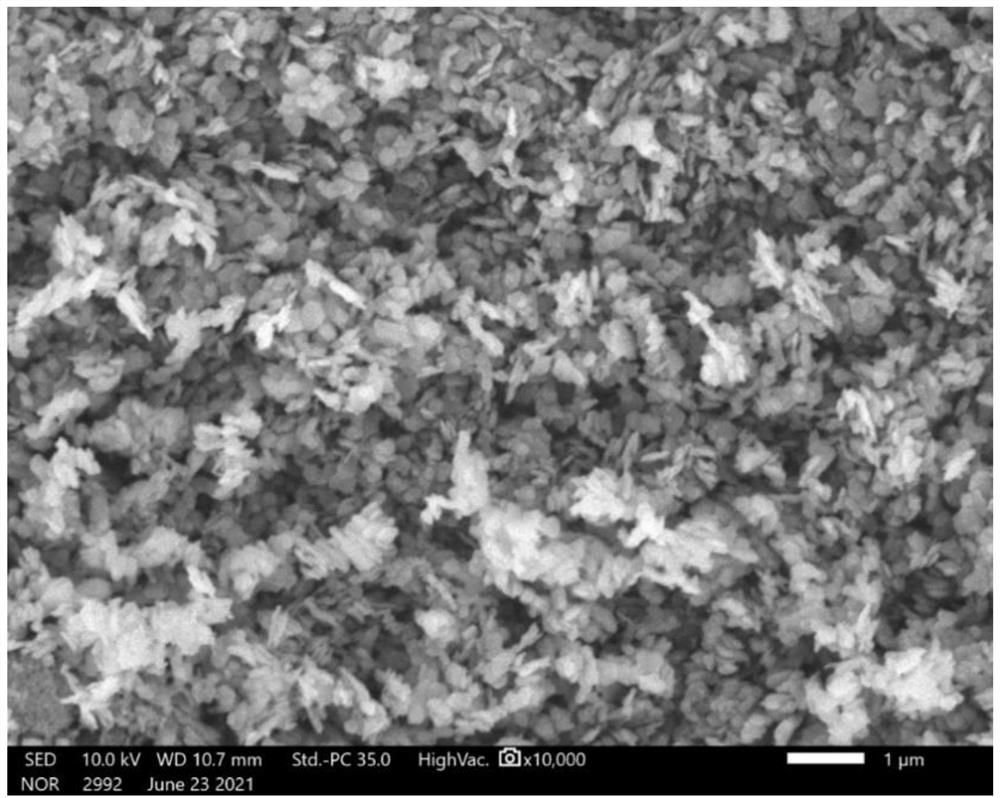

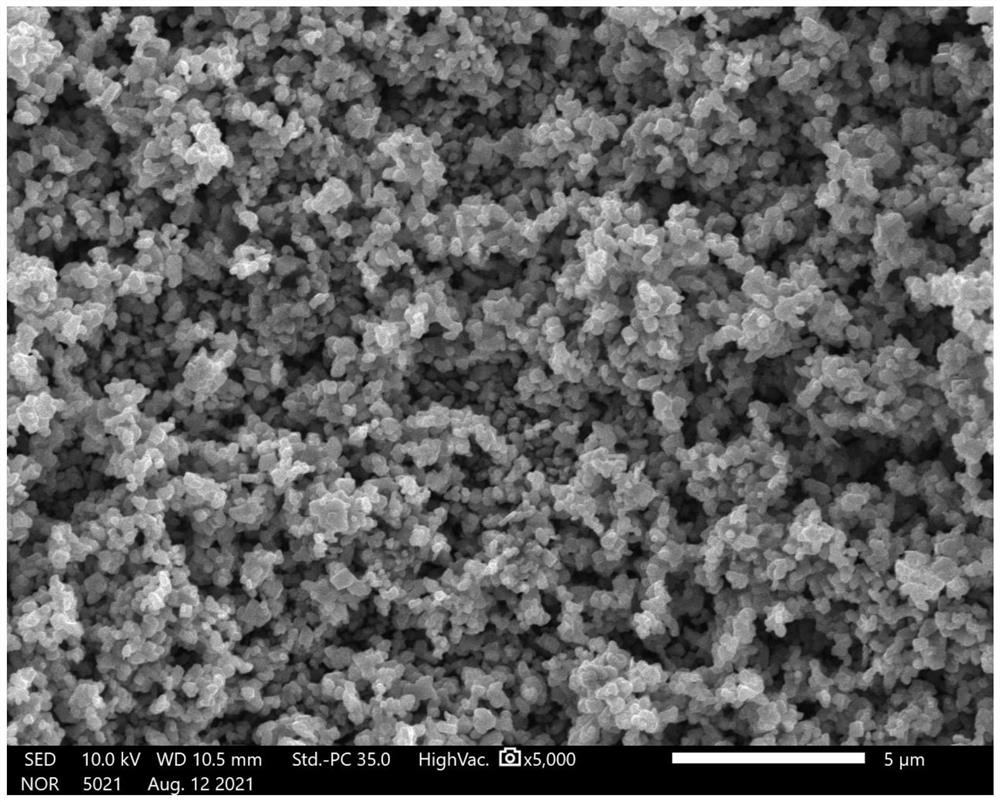

[0030] S1. Preparation of nano-flaky cobalt tetroxide: inject 40L of ammonia water with a concentration of 10g / L into the reactor as the bottom liquid, start stirring, and slowly add 160L of cobalt chloride solution with a concentration of 80g / L and 140L with a mass fraction of 20% sodium hydroxide solution, after the feeding is completed, the temperature of the material is raised to 60°C, and the temperature is kept for 1.5 hours to form a cobalt hydroxide slurry with flaky primary particles. In order to prevent the cobalt hydroxide from being oxidized, feed Nitrogen for protection; after the heat preservation is over, press filter and wash the above slurry, add pure water to the filter cake obtained after the slurry press filter and water wash to make a slurry, and perform flash drying. The air temperature for flash drying is 300-350°C , and then crushed by a jet mill to obtain flake cobalt hydroxide without agglomeration and adhesion; place the weighed cobalt hydroxide in a ...

Embodiment 2

[0040] S1. Preparation of nano-flaky cobalt tetroxide: inject 40L of ammonia water with a concentration of 10g / L into the reactor as the bottom liquid, start stirring, and slowly add 160L of cobalt chloride solution with a concentration of 80g / L and 140L with a mass fraction of 20% sodium hydroxide solution, after the feeding is completed, the temperature of the material is raised to 60°C, and the temperature is kept for 1.5 hours to form a cobalt hydroxide slurry with flaky primary particles. In order to prevent the cobalt hydroxide from being oxidized, feed Nitrogen for protection; after the heat preservation is over, press filter and wash the above slurry, add pure water to the filter cake obtained after the slurry press filter and water wash to make a slurry, and perform flash drying. The air temperature for flash drying is 300-350°C , and then crushed by a jet mill to obtain flake cobalt hydroxide without agglomeration and adhesion; place the weighed cobalt hydroxide in a ...

Embodiment 3

[0049] S1. Preparation of nano-flaky cobalt tetroxide: inject 40L of ammonia water with a concentration of 10g / L into the reactor as the bottom liquid, start stirring, and slowly add 160L of cobalt chloride solution with a concentration of 80g / L and 140L with a mass fraction of 20% sodium hydroxide solution, after the feeding is completed, the temperature of the material is raised to 60°C, and the temperature is kept for 1.5 hours to form a cobalt hydroxide slurry with flaky primary particles. In order to prevent the cobalt hydroxide from being oxidized, feed Nitrogen for protection; after the heat preservation is over, press filter and wash the above slurry, add pure water to the filter cake obtained after the slurry press filter and water wash to make a slurry, and perform flash drying. The air temperature for flash drying is 300-350°C , and then crushed by a jet mill to obtain flake cobalt hydroxide without agglomeration and adhesion; place the weighed cobalt hydroxide in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com