Camellia oil capsule and preparation method thereof

A technology for preparing capsules and camellia oil, which is applied in the production of fat oil/fat, food ingredients containing oil, edible oil/fat components, etc., can solve the problems of loss of effective components of camellia oil, inaccurate temperature control, and low absorption of effective components. , to achieve the effect of being conducive to food digestion, improving utilization, and improving the applicable population

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

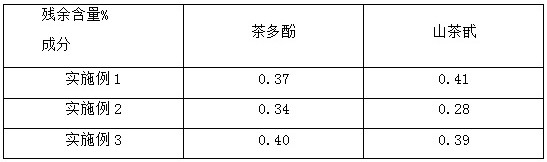

Embodiment 1

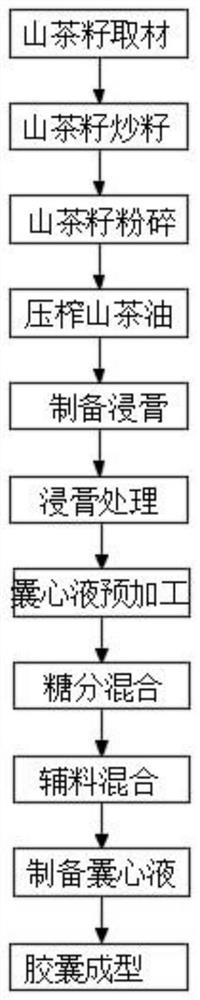

[0034] Refer to attached figure 1 , a kind of camellia oil capsule provided by the present invention, in order to achieve the above object, the present invention provides the following technical scheme: a kind of camellia oil capsule, comprises main material and auxiliary material, (according to the mass percentage calculation) main material comprises camellia oil 20%, auxiliary material Including 4% deep sea fish oil, 10% astragalus crude polysaccharide, 8% edible gelatin, 7% hyaluronic acid, 14% chitosan, 5% sodium alginate, 4% vitamin B, 3% xanthan gum, 5% 65% ethanol , the balance being sterile water;

[0035] Further, the specific operation steps are as follows:

[0036] S1: Material of camellia seeds: Pick mature camellia seeds by manual picking, select high-quality camellia seeds with full particles, no damage on the surface, and no damage after picking, then put the camellia seeds in clean water and wash them, and then Take out the camellia seeds and drain the water ...

Embodiment 2

[0048] Refer to attached figure 1 , a kind of camellia oil capsule provided by the present invention, in order to achieve the above object, the present invention provides the following technical scheme: a kind of camellia oil capsule, comprises main material and auxiliary material, (according to mass percentage calculation) main material comprises camellia oil 23%, auxiliary material Including deep sea fish oil 6%, astragalus crude polysaccharide 14%, edible gelatin 10%, hyaluronic acid 10%, chitosan 17%, sodium alginate 7%, vitamin B6%, xanthan gum 5%, 65% ethanol 5% , the balance being sterile water;

[0049] Further, the specific operation steps are as follows:

[0050] S1: Material of camellia seeds: Pick mature camellia seeds by manual picking, select high-quality camellia seeds with full particles, no damage on the surface, and no damage after picking, then put the camellia seeds in clean water and wash them, and then Remove the camellia seeds, drain and set aside;

...

Embodiment 3

[0062] Refer to attached figure 1 , a kind of camellia oil capsule provided by the present invention, in order to achieve the above object, the present invention provides the following technical scheme: a kind of camellia oil capsule, comprises main material and auxiliary material, (according to the mass percentage calculation) main material comprises camellia oil 26%, auxiliary material Including deep sea fish oil 8%, astragalus crude polysaccharide 18%, edible gelatin 12%, hyaluronic acid 13%, chitosan 19%, sodium alginate 9%, vitamin B 8%, xanthan gum 7%, 65% ethanol 5% , the balance being sterile water;

[0063] Further, the specific operation steps are as follows:

[0064] S1: Material of camellia seeds: Pick mature camellia seeds by manual picking, select high-quality camellia seeds with full particles, no damage on the surface, and no damage after picking, then put the camellia seeds in clean water and wash them, and then Remove the camellia seeds, drain and set aside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com