Milk shred mold cup with degradation function, and preparation method thereof

A molded cup and milk silk technology, applied in chemical instruments and methods, brassieres, single-component polyester artificial filaments, etc., can solve problems such as general hygroscopicity and air permeability, non-biodegradable materials, and reduced environmental protection. Achieve the effect of overcoming the rigid feeling, not easy to degumming, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A milk silk mold cup with degradable function is characterized in that its constituent materials include polylactic acid fiber, polyamide fiber, synthetic elastic fiber, silica gel, and polyester jersey.

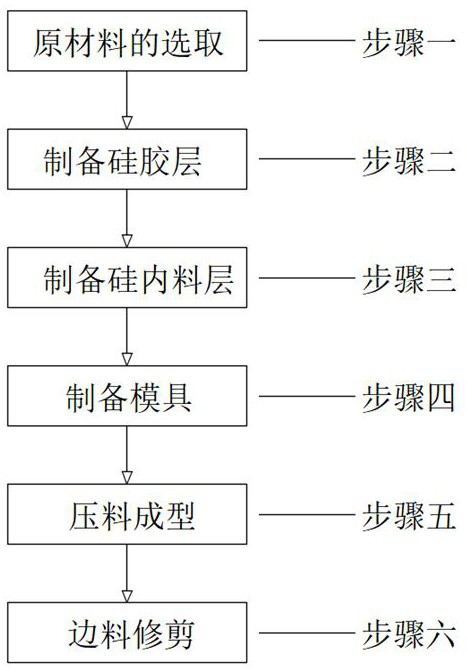

[0028] A method for preparing a milk silk mold cup with a degradation function, comprising step 1, selecting raw materials; step 2, preparing a silica gel layer; step 3, preparing an inner material layer; step 4, preparing a mould; Step 6, edge material trimming;

[0029] In the above step 1, the staff selects polylactic acid fibers, polyamide fibers, synthetic elastic fibers, silica gel, polyester jersey, and high-density sponges that meet the requirements according to the quality requirements, and inspects the quality of the raw materials to ensure that the quality is qualified;

[0030] In the above-mentioned step 2, the staff makes the silicone material into the silicone layer through the injection molding machine, and makes the polyamide fiber and the synthetic e...

Embodiment 2

[0036] The quality requirements for raw material selection in step 1 include the selection of appearance quality, weight components, and hardness; the silicone layer can increase the shape of the chest, and the touch is similar to the texture of the natural texture of the chest. The stiff feeling of traditional corsets has good elasticity, and it is not easy to produce wrinkles and yellowing; polylactic acid fibers are made of corn, cassava, sugar cane, straw, straw and other starchy and cellulose-containing plants as raw materials. Glucose is obtained through the fermentation of biological enzymes, which is fermented by lactic acid bacteria to become lactic acid, then polymerized into resin, and then made into milk silk by spinning. It is a kind of biological fiber that can be completely biodegradable. The function can be decomposed into carbon dioxide and water. It will not emit poisonous gas when burning. It has a great effect on environmental protection. At the same time, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com