Preparation method of methane cracking catalyst

A technology for cracking catalysts and methane, which is applied in the field of preparation of methane cracking catalysts. It can solve the problems of waste liquid generation, waste of water, and uncontrollable loading of active components, etc., and achieve the goals of reducing environmental pollution, high conversion rate, and short preparation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

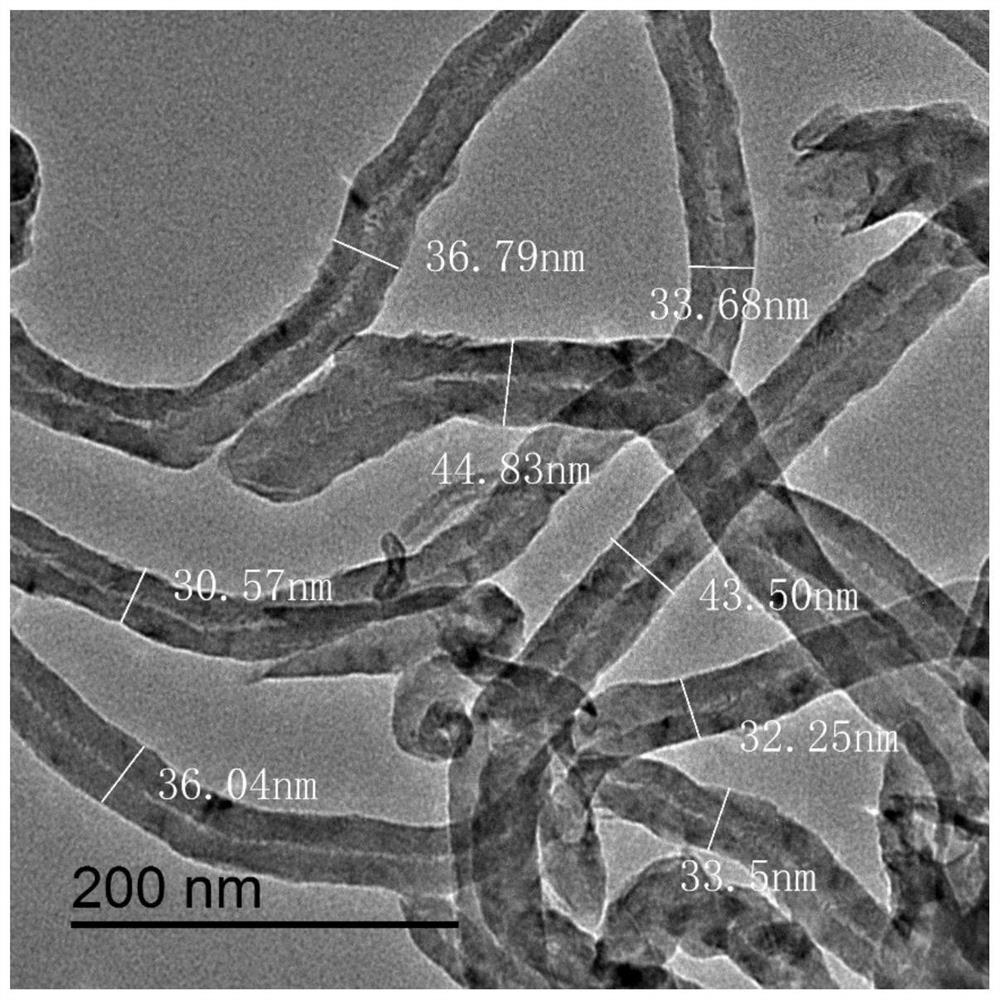

Image

Examples

Embodiment 1

[0038] A kind of preparation method of methane cracking catalyst, described preparation method comprises the steps:

[0039] (1) SiO 2 As a carrier, after drying in an oven at 110°C for 4 hours, take it out and place it in a desiccator to cool to room temperature;

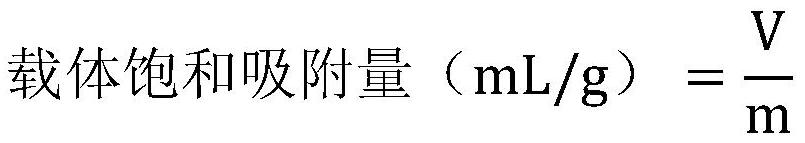

[0040] (2) Weigh 3g SiO 2 Place in a ceramic crucible, use an acid burette to add deionized water drop by drop to the carrier, and stir at the same time during the dropping process until the deionized water just soaks the carrier, and the measured saturated adsorption capacity is 3.4mL / g;

[0041] (3) Weigh 19.1g Ni(NO 3 ) 2 ·6H 2 O and 3.0g Fe(NO3 ) 3 9H 2 O, mixed with deionized water to prepare 51 mL of metal salt solution.

[0042] (4) Add the metal salt solution dropwise into the 15.0 g carrier obtained in step (1), and stir while dripping. After the addition is completed, let stand at room temperature for 2 hours and dry at 80°C for 10 hours; the purpose of standing is to make the metal salt solution ...

Embodiment 2

[0046] A kind of preparation method of methane cracking catalyst, described preparation method comprises the steps:

[0047] (1) Add γ-Al 2 o 3 As a carrier, after drying in an oven at 120°C for 1 hour, take it out and place it in a desiccator to cool to room temperature;

[0048] (2) Weigh 3g γ-Al 2 o 3 Place in a ceramic crucible, use an acid burette to add deionized water drop by drop to the carrier, and stir at the same time during the dropping process until the deionized water just soaks the carrier, and the measured saturated adsorption capacity is 1.5mL / g;

[0049] (3) Weigh 19.9g Ni(NO 3 ) 2 ·6H 2 O and 6.9g Fe(NO 3 ) 3 9H 2 O, mixed with a mixed solution of deionized water and ethanol (ethanol: deionized water = 1:1) to prepare 22.5 mL of a metal salt aqueous solution.

[0050] (4) Add the metal salt solution dropwise into the 15.0 g carrier obtained in step (1), and stir while dripping. After the addition is completed, let stand at room temperature for 1 ho...

Embodiment 3

[0055] A kind of preparation method of methane cracking catalyst, described preparation method comprises the steps:

[0056] (1) Add γ-Al 2 o 3 As a carrier, after drying in an oven at 120°C for 1 hour, take it out and place it in a desiccator to cool to room temperature;

[0057] (2) Weigh 3g γ-Al 2 o 3 Place in a ceramic crucible, use an acid burette to add deionized water drop by drop to the carrier, and stir at the same time during the dropping process until the deionized water just soaks the carrier, and the measured saturated adsorption capacity is 1.5mL / g;

[0058] (3) Weigh 19g Ni(NO 3 ) 2 ·6H 2 O, 0.8g Cu(NO 3 ) 2 ·3H 2 O and 6.5gFe(NO 3 ) 3 9H 2 O was mixed with deionized water to prepare 22.5 mL of metal salt solution.

[0059] (4) Add the metal salt solution dropwise into the carrier obtained in step (1), and stir while dripping. After the dropwise addition is completed, let stand at room temperature for 4 hours, and dry at 120°C for 8 hours; the purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com