SnS2 nanosheet array structure with photo-thermal function and preparation method thereof

A nanosheet array and array structure technology, applied in chemical instruments and methods, heating, clothing, etc., to achieve the effects of strong adaptability, uniform shape, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

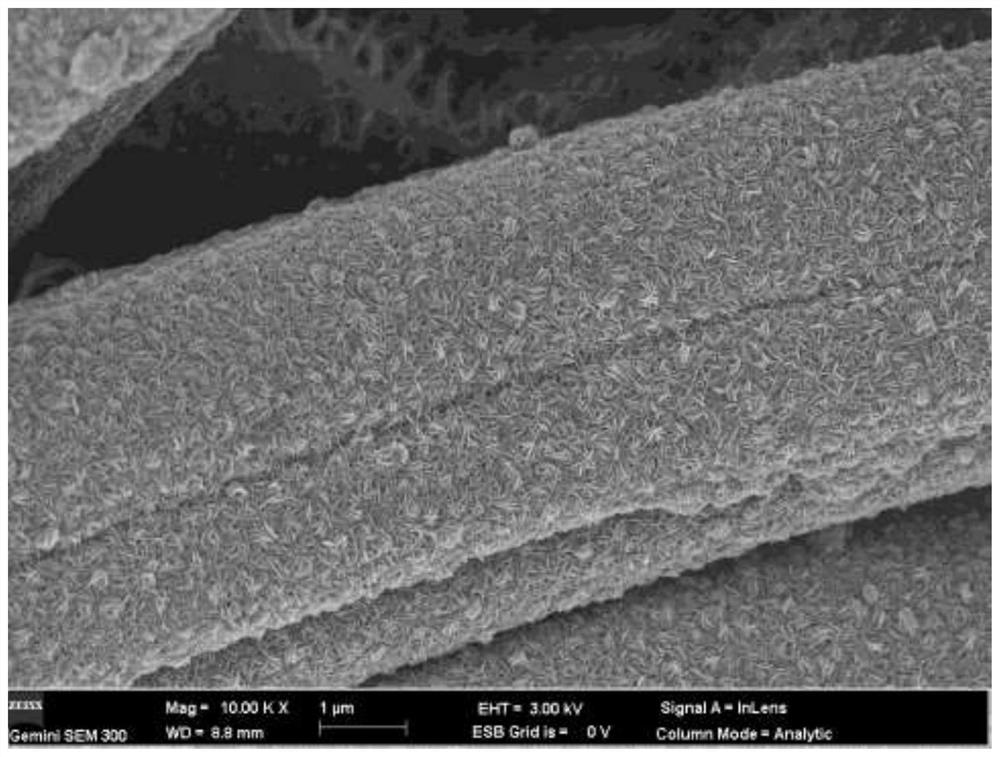

[0021] 1.0mmol SnCl 2 2H 2 O and 1.0mmol thioacetamide were uniformly dispersed in 1.6mL isopropanol, and magnetically stirred for 20min; then 1.0g polyvinylpyrrolidone was dispersed in 30mL isopropanol, and magnetically stirred for 30min to fully dissolve; then SnCl 2 2H 2 The dispersion liquid of O and thioacetamide was successively added to the isopropanol solution dissolved in polyvinylpyrrolidone, and magnetically stirred for 30 minutes; In the lining of the reaction kettle, after the stainless steel reaction kettle was sealed, the solvothermal reaction was carried out at 170°C for 10h; after the reaction kettle was naturally cooled to room temperature, the substrate was washed three times with distilled water and absolute ethanol, and vacuum-dried at 40°C to obtain SnS with array structure on the surface 2 Nanosheets coated carbon cloth.

Embodiment 2

[0023] 0.5mmol SnCl 2 2H 2 O and 0.5mmol thioacetamide were uniformly dispersed in 1.0mL isopropanol, and magnetically stirred for 20min; then 0.5g polyvinylpyrrolidone was dispersed in 30mL isopropanol, and magnetically stirred for 30min to fully dissolve; then SnCl 2 2H 2 The dispersion liquid of O and thioacetamide was successively added to the isopropanol solution dissolved in polyvinylpyrrolidone, and magnetically stirred for 30 minutes; In the lining of the reaction kettle, after the stainless steel reaction kettle was sealed, the solvothermal reaction was carried out at 170°C for 10h; after the reaction kettle was naturally cooled to room temperature, the substrate was washed three times with distilled water and absolute ethanol, and vacuum-dried at 40°C to obtain SnS with array structure on the surface 2 Nanosheets coated carbon cloth.

Embodiment 3

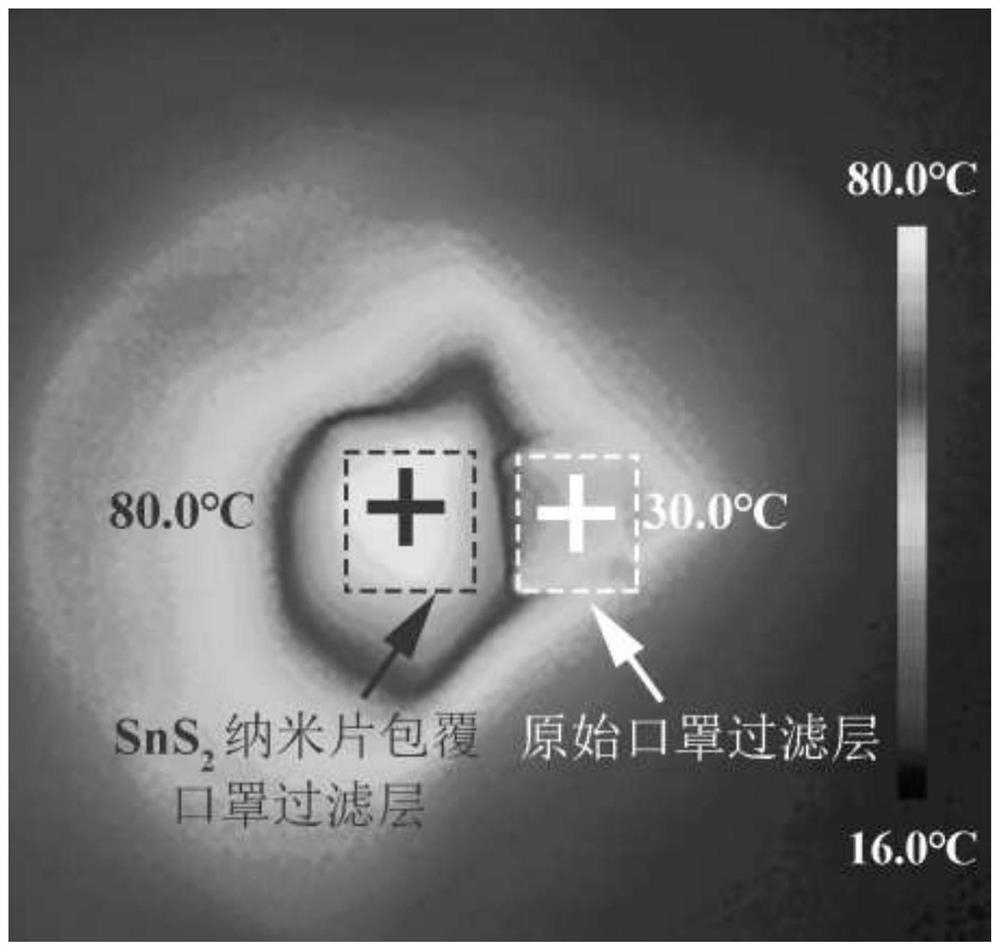

[0025] 0.8mmol SnCl 4 ·5H 2 O and 0.8mmol thioacetamide were uniformly dispersed in 1.6mL isopropanol, and magnetically stirred for 20min; then 1.0g polyvinylpyrrolidone was dispersed in 30mL isopropanol, and magnetically stirred for 30min to fully dissolve; then SnCl 4 ·5H 2 The dispersions of O and thioacetamide were successively added to the isopropanol solution in which polyvinylpyrrolidone was dissolved, and magnetically stirred for 30 minutes; after mixing evenly, the above mixed solution was transferred to a filter layer of 1cm×1cm disposable medical mask. In the lining of the polytetrafluoroethylene reactor, after the stainless steel reactor was sealed, the solvothermal reaction was carried out at 160°C for 12 hours; after the reactor was naturally cooled to room temperature, the substrate was washed three times with distilled water and absolute ethanol, and then heated at 40°C SnS with array structure on the surface obtained after vacuum drying 2 Nanosheets coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com