Copper sulphide@mesoporous silica nanocomposite and preparation method and application thereof

A technology of mesoporous silica and nanomaterials, applied in the direction of nanotechnology, nanotechnology, wave energy or particle radiation treatment materials, etc., can solve the harsh conditions of preparation and functionalization, affect the stability of photothermal performance, and shape Easy to change and other problems, to achieve the effect of high photothermal conversion efficiency, low cost, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of copper sulfide / silica nanoparticles

[0039] (1) Synthesis of mesoporous silica nanomaterials with mercapto groups on the surface;

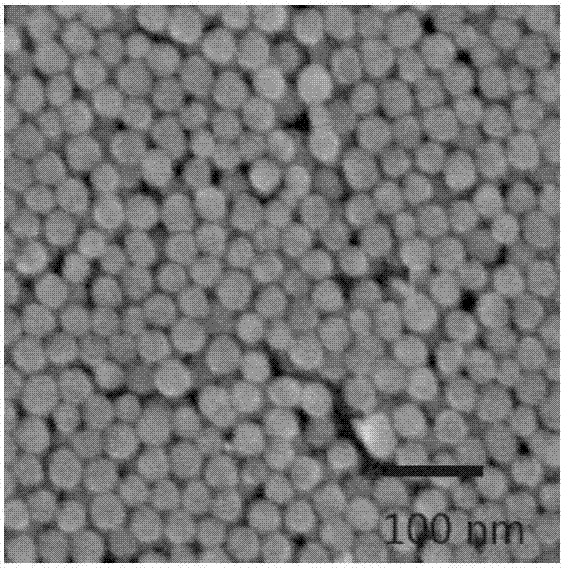

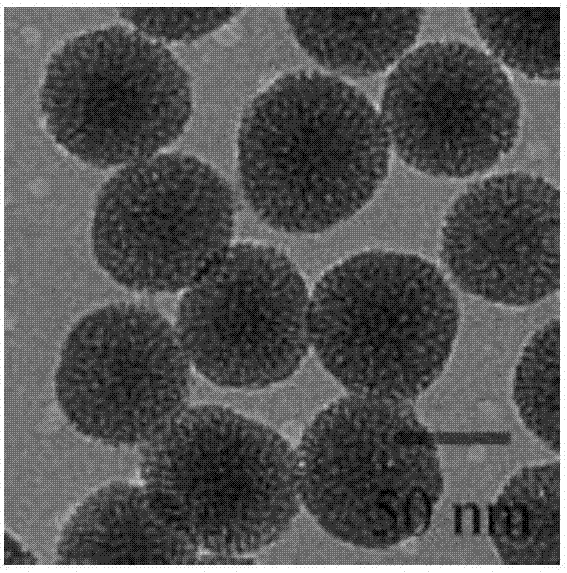

[0040] Mix 64mL water, 11.25mL ethanol, 0.2g diethanolamine and 10.4mL cetyltrimethylammonium chloride aqueous solution (25wt%), stir the reaction at 60°C for 0.5h, then add 7mL tetraethoxysilane And 0.6mL mercaptopropyltrimethoxysilane, continue to stir the reaction for 3h. After the reaction is completed, centrifuge and wash 2-5 times with a mixture of ethanol and water, then slowly add 15mL of concentrated hydrochloric acid into 120mL of ethanol solution to form a mixed solution, and let the above-mentioned reaction product be dispersed in the mixed solution. Stir and react at 60° C. for 24 h, and finally, centrifuge and wash 2-5 times with a mixture of ethanol and water. The SEM graphics obtained from the test are as follows figure 1 As shown, the TEM pattern is as figure 2 As shown, it can be seen that the particle...

Embodiment 2

[0045] Photothermal Properties of Copper Sulfide Modified Silica Composite Nanomaterials

[0046] The CuS@mSiO obtained in Example 1 2 The material is formulated into solutions of different concentrations (0, 12, 24, 60, 100 and 120ppm), and the laser is used at 980nm with 0.72W / cm 2 The power of light is irradiated for 5 minutes, and the obtained temperature curves of different concentrations of materials are as follows: Figure 7 Shown, 120ppm concentration of CuS@mSiO 2 The light stability diagram of the material is shown in Figure 8 shown.

[0047] from Figure 7 with Figure 8 It can be seen that the prepared CuS@mSiO 2 The material has obvious photothermal function. With the prolongation of the light time, the temperature rise of the material is more obvious, and it has a certain photothermal stability. According to Roper's method to calculate the light-to-heat conversion efficiency, it can be known that the light-to-heat conversion efficiency is 27.4%.

Embodiment 3

[0049] Preparation of copper sulfide / silica nanoparticles (copper chloride + sodium thiosulfate)

[0050] (1) Synthesis of mesoporous silica nanomaterials with mercapto groups on the surface;

[0051] This process is exactly the same as step (1) in Example 1.

[0052] (2) Synthesis of Copper Sulfide Modified Mesoporous Silica Composite Nanomaterials - Heating Reflux Method

[0053] Take 20 mg of the above sample and disperse it in 20 mL of water, adjust the pH of the solution to 7.5, stir for 20 minutes, add 200 μL of 0.1M copper chloride solution, stir for 5 hours, add 100 μL of 0.2M sodium thiosulfate solution drop by drop, at 100 Refluxed at ℃ for 7h to obtain the target product. The SEM graphics obtained from the test are as follows Figure 9 shown.

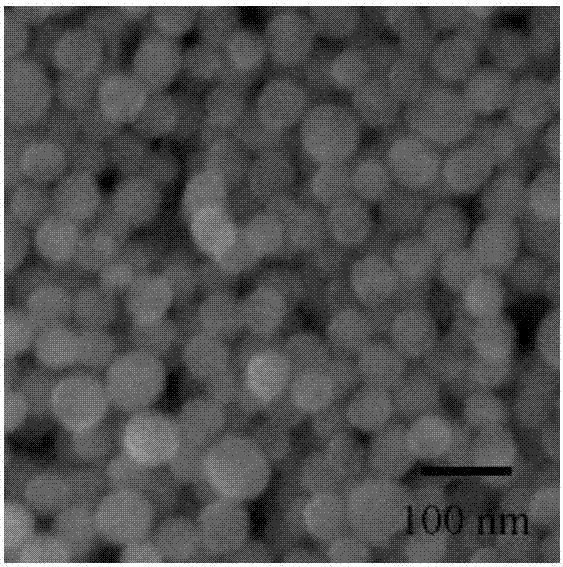

[0054] from Figure 9 It can be seen from the figure that the particle structure of the copper sulfide-modified mesoporous silica composite nanomaterial obtained by this method is slightly damaged compared with the exper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com