Multi-layer composite artificial stone plate with smelting slag as raw material and preparation method thereof

A multi-layer composite, artificial stone technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problem of high cost, enhance mechanical strength, overcome stockpiling treatment, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

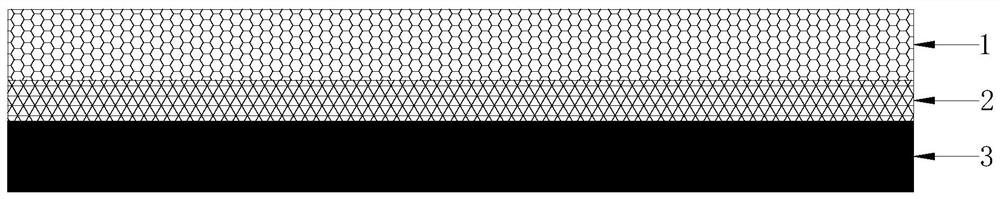

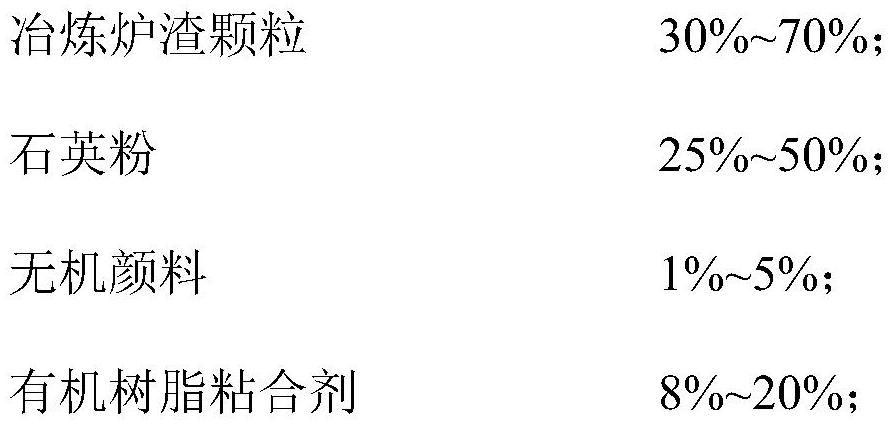

[0040] A multi-layer composite artificial stone plate material with smelting slag is a raw material, which is shown figure 1 Indicated. The surface layer 1, the intermediate layer 2 and the underlayer 3 are included, the surface layer material from 43% nickel smelting slag particles (10 ~ 20 mesh), 40% of quartz powder (350 ~ 400 mesh), 2% inorganic pigment (350 ~ 400 mesh and 15% of the acrylic resin; the intermediate layer material includes a metal fiber having a long diameter ratio of greater than 100; the bottom material is from 30% nickel smelting slag particles (10 ~ 20 mesh), 30% of pulverization coal. The gray filler (350 ~ 400 mesh) and 40% of silicate cement composition.

[0041] The multi-layer composite artificial stone plate was prepared by the following method:

[0042] (1) Follow the substrate ratio of the underlying material, mix the nickel slag particles, fly ash filling, silicate and appropriate amount of water mixed, and arrange the mixture in the mold in the mo...

Embodiment 2

[0047] A multi-layer composite artificial stone plate material with smelting slag is a raw material, which is shown figure 1 Indicated. The surface layer 1, the intermediate layer 2 and the underlayer 3 are included, the surface layer material from 55% nickel smelting slag particles (10 ~ 20 mesh), 30% quartz powder (350 ~ 400 mesh), 1% inorganic pigment (350 ~ 400 mesh) and 14% unsaturated resin; the intermediate layer material includes glass fibers having a long diameter ratio greater than 100; the bottom material is from 45% nickel smelting slag particles (10 ~ 20 mesh), 25% glass Powder filling (350 ~ 400 mesh) and 30% silicate cement composition.

[0048] The multi-layer composite artificial stone plate was prepared by the following method:

[0049] (1) Follow the underlying material ratio, mix the nickel smelting slag particles, glass powder filled, silicate and appropriate amount of water mixed, the mixture is placed in the mold according to the desired thickness, and obtai...

Embodiment 3

[0054] A multi-layer composite artificial stone plate material with smelting slag is a raw material, which is shown figure 1 Indicated. The surface layer 1, the intermediate layer 2 and the underlayer 3 are included, the surface layer material from 65% nickel smelting slag particles (10 ~ 20 mesh), 25% quartz powder (350 ~ 400 mesh), 2% inorganic pigment (350 ~ 400 mesh) and 8% of epoxy resin; the intermediate layer material includes ultra-high molecular weight polyethylene fibers having a long diameter ratio greater than 100; the bottom material is from 60% nickel smelting slag particles (10 ~ 20 mesh), 15% ceramic powder filled (350 ~ 400 mesh) and 25% of silicate cement composition.

[0055] The multi-layer composite artificial stone plate was prepared by the following method:

[0056] (1) A mixture of nickel smelting slag particles, ceramic powder filled, silicate cement and appropriate amount of water is mixed according to the underlying material ratio, and the mixture is pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com