Halogen-free flame-retardant polypropylene material for automotive interiors and preparation method thereof

A technology for flame-retardant polypropylene and automotive interiors, applied in the field of polymer material modification, can solve problems such as poor odor, low toughness, and precipitation of flame retardants, and achieve increased compatibility, good flame retardancy, and improved toughness. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

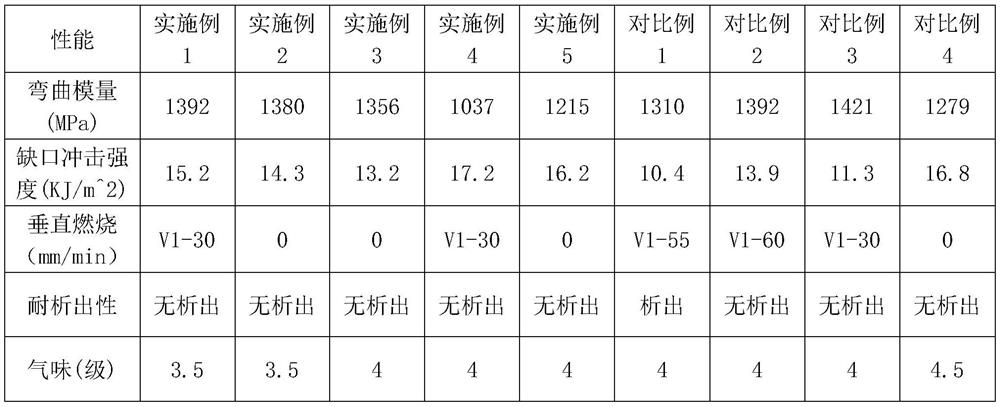

Examples

Embodiment 1

[0028] A halogen-free flame-retardant polypropylene material for automotive interiors, comprising the following raw materials in parts by weight: 55 parts of polypropylene, 12.5 parts of coated ammonium polyphosphate, 6.25 parts of piperazine pyrophosphate, and 6.25 parts of synergistic flame retardant , 0.5 parts of coupling agent, 5 parts of inorganic filler, 15 parts of toughening agent, 0.5 part of deodorant, 0.6 part of stabilizer;

[0029] Among them, the preparation method of coated ammonium polyphosphate is: add 50g APP to 200mL of absolute ethanol, ultrasonically disperse for 0.5h, disperse evenly, adjust PH≈6 with 15% hydrochloric acid, slowly raise the temperature to 85°C, first add an appropriate amount of For melamine-formaldehyde prepolymer, keep the temperature at 85°C, keep stirring for 2 hours, then add the same amount of epoxy resin, and add a curing agent to react for 0.5 hours to cure the epoxy resin (EP) and make melamine-formaldehyde resin (MF) ) and epox...

Embodiment 2

[0035] A halogen-free flame-retardant polypropylene material for automotive interiors, comprising the following raw materials in parts by weight: 52 parts of polypropylene, 14 parts of coated ammonium polyphosphate, 7 parts of piperazine pyrophosphate, and 7 parts of synergistic flame retardant , 0.8 parts of coupling agent, 5 parts of inorganic filler, 15 parts of toughening agent, 0.5 part of deodorant, 0.3 part of stabilizer;

[0036]Among them, the preparation method of coated ammonium polyphosphate is: add 50g APP to 200mL of absolute ethanol, ultrasonically disperse for 0.5h, disperse evenly, adjust PH≈6 with 15% hydrochloric acid, slowly raise the temperature to 85°C, first add an appropriate amount of For melamine-formaldehyde prepolymer, keep the temperature at 85°C, keep stirring for 2 hours, then add the same amount of epoxy resin, and add a curing agent to react for 0.5 hours to cure the epoxy resin (EP) and make melamine-formaldehyde resin (MF) ) and epoxy resin d...

Embodiment 3

[0042] A halogen-free flame-retardant polypropylene material for automotive interiors, comprising the following raw materials in parts by weight: 50 parts of polypropylene, 15 parts of coated ammonium polyphosphate, 7.5 parts of piperazine pyrophosphate, and 7.5 parts of synergistic flame retardant , 1.5 parts of coupling agent, 5 parts of inorganic filler, 15 parts of toughening agent, 0.5 part of deodorant, 0.6 part of stabilizer;

[0043] Among them, the preparation method of coated ammonium polyphosphate is: add 50g APP to 200mL of absolute ethanol, ultrasonically disperse for 0.5h, disperse evenly, adjust PH≈6 with 15% hydrochloric acid, slowly raise the temperature to 85°C, first add an appropriate amount of For melamine-formaldehyde prepolymer, keep the temperature at 85°C, keep stirring for 2 hours, then add the same amount of epoxy resin, and add a curing agent to react for 0.5 hours to cure the epoxy resin (EP) and make melamine-formaldehyde resin (MF) ) and epoxy re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com