Nano attapulgite composite flame retardant and preparation method thereof

A nano-attapulgite and nano-composite technology is applied in the field of nano-attapulgite composite flame retardant and its preparation, which can solve problems such as environmental pollution and achieve the effects of improving comprehensive performance, recyclable solvent and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Attapulgite purification: add 30g of attapulgite powder to a 500ml two-neck bottle equipped with mechanical stirring, add 0.6g of sodium hexametaphosphate modifier, and then add 300ml of deionized water as a solvent, and control the temperature to react at 35-55 °C 4h, after the reaction was completed, it was lowered to room temperature, and the product was statically removed to remove large particles of impurities, then centrifuged, washed, and dried, and the obtained purified product was placed in an oven at 60 °C for 12h to obtain an off-white solid.

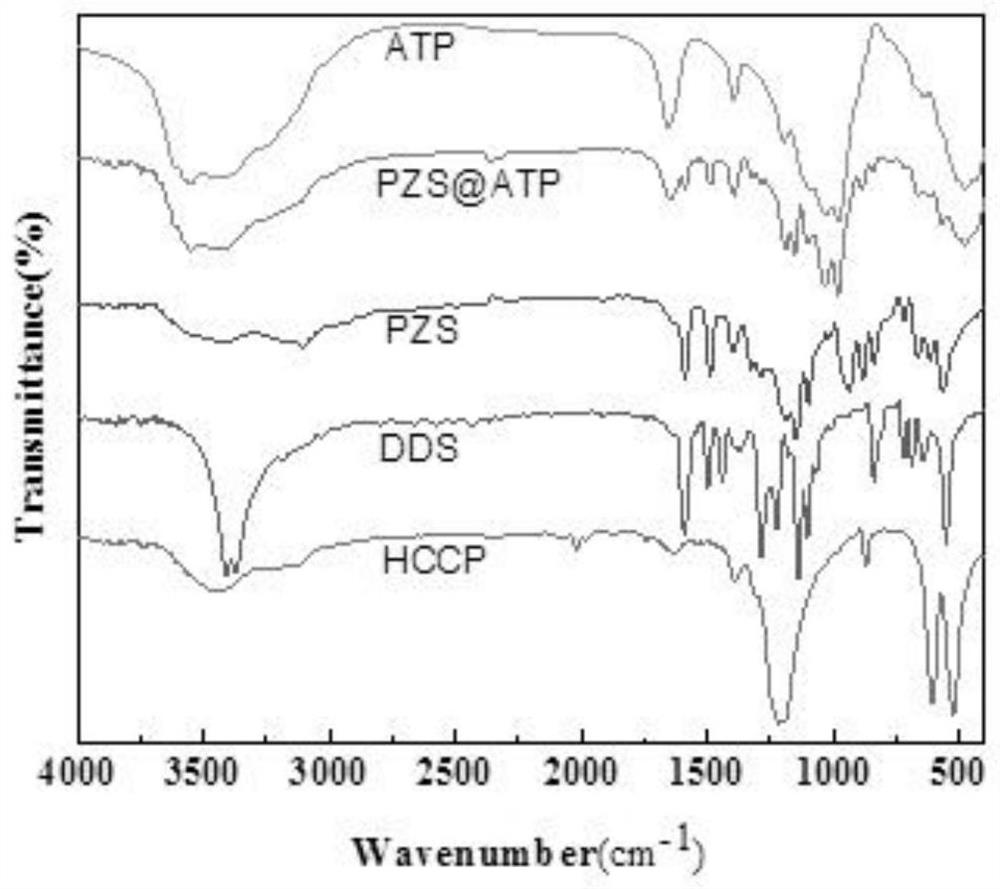

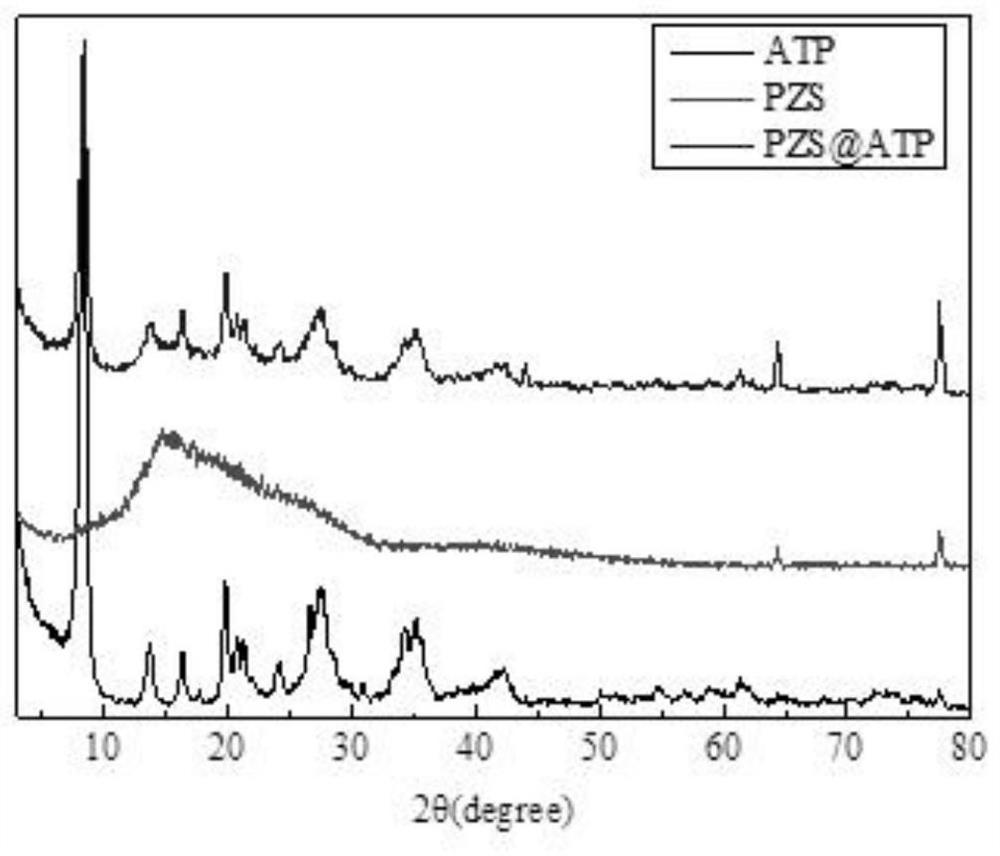

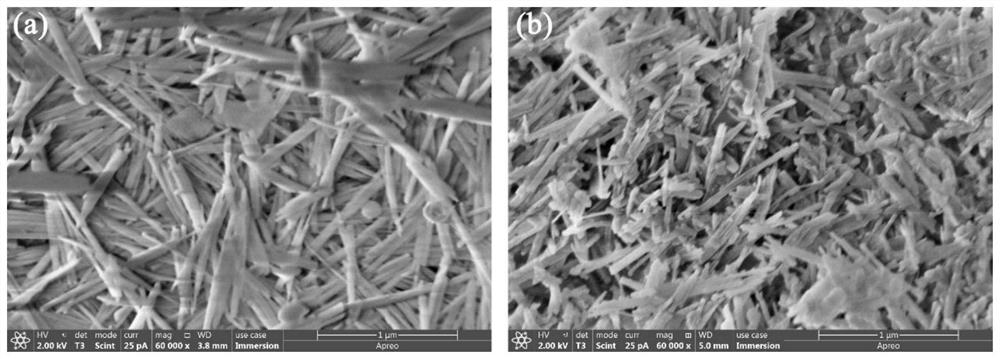

[0035] Preparation of composite flame retardant: take 10g of the above attapulgite solid powder, disperse it in 500ml of absolute ethanol, add 8.6g of 4,4-dihydroxydiphenylsulfone (BPS), fully dissolve and add 14ml of triethylamine (TEA), Accurately weigh 4g of hexachlorocyclotriphosphazene (HCCP) and dissolve it in 80ml of absolute ethanol, place it in a 100ml constant pressure dropping funnel, start the mechanical sti...

Embodiment 2

[0037]Attapulgite purification: add 30g of attapulgite powder to a 500ml two-necked bottle equipped with mechanical stirring, add 5ml of concentrated hydrochloric acid as a modifier, and then add 300ml of deionized water as a solvent, and control the temperature to react at 35 ~ 55 ℃ for 4h, After the reaction was completed, it was lowered to room temperature, and the product was statically removed to remove large particles of impurities, then centrifuged, washed, and dried. The obtained purified product was dried in an oven at 60°C for 12 hours to obtain an off-white solid.

[0038] Preparation of composite flame retardant: take 10g of the above attapulgite solid powder, disperse it in 500ml of absolute ethanol, add 8.6g of 4,4-dihydroxydiphenylsulfone (BPS) to fully dissolve, add 14ml of triethylamine (TEA), Accurately weigh 4g of hexachlorocyclotriphosphazene (HCCP) and dissolve it in 80ml of absolute ethanol, place it in a 100ml constant pressure dropping funnel, start the ...

Embodiment 3

[0046] Attapulgite purification: add 30g of attapulgite powder to a 500ml two-necked bottle equipped with mechanical stirring, add 50ml of 10% NaOH as a modifier, and then add 300ml of deionized water as a solvent, and control the temperature to react at 35~55℃ for 4h After the reaction was completed, it was lowered to room temperature, and the product was statically removed to remove large particles of impurities, and then centrifuged, washed, and dried.

[0047] Preparation of composite flame retardant: take 10g of the above attapulgite solid powder, disperse it in 500ml of absolute ethanol, add 7.8g of 4,4-dihydroxydibenzylmethane (DADPM) to fully dissolve, add 14ml of triethylamine (TEA), Accurately weigh 4g of hexachlorocyclotriphosphazene (HCCP) and dissolve it in 80ml of absolute ethanol, place it in a 100ml constant pressure dropping funnel, start the mechanical stirring, and start to add the mixed solution dropwise. The reaction temperature is 60° C., the reaction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com