Production process of high-efficiency Q235B micro-titanized steel grade

A Q235B, production process technology, applied in the field of high-efficiency Q235B micro-titanium steel production process, can solve the problems of low cost and high efficiency, unable to meet the cold bending process, etc., to increase the continuous casting casting speed, improve internal quality, Effect of reducing crack susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

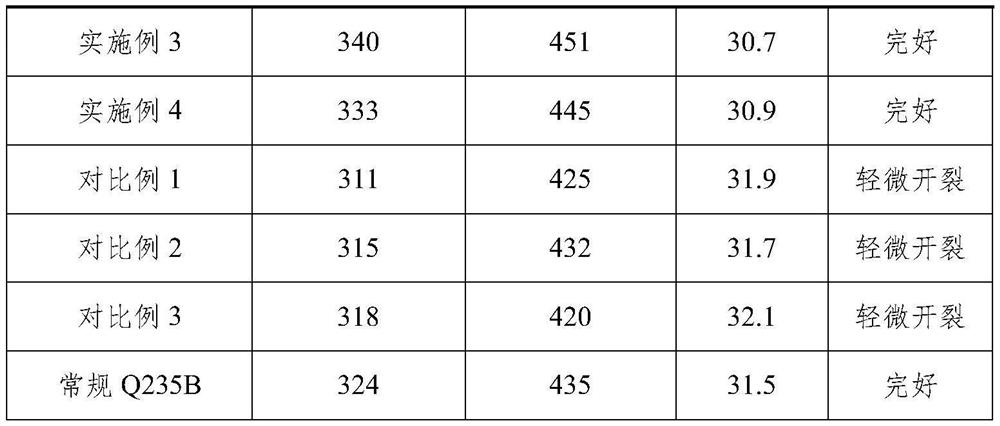

Examples

Embodiment 1

[0036] Composition: C: 0.06%, Si: 0.06%, Mn: 0.40%, P: 0.025%, S: 0.020%, Als: 0.020%, Ti: 0.040%, the balance is Fe.

[0037] Routing: Mixer ladle or furnace off tank → → → argon deoxygenated alloy slab caster Station → → → heating the slab in the rough rolling → cropping and pre-finishing rolling → → truncated finishing train cooled rolling → → → roll bale collector, identified, weighed, test volume → storage → unloading.

[0038] When steel converter 1min, into lime 2kg / t, desulfurizing agent 5kg / t, wherein the desulfurizing agent comprises the following components: CaO: 51%, SiO 2 : 4%, Al 2 O 3 : 30%, Al: 12%, CaF 2 : 3%.

[0039] When opening the converter steel ladle bottom blowing argon, and the control flow 300-350L / min, argon time 12min. Wherein the tapping time control 4min.

[0040] The deoxidation alloy target composition, adding titanium iron alloy according to conventional methods.

[0041]When the argon station is refined, the feed point is located directly a...

Embodiment 2

[0044] Composition: C: 0.05%, Si: 0.07%, Mn: 0.45%, P: 0.022%, S: 0.018%, ALS: 0.027%, Ti: 0.035%, the margin is Fe.

[0045] Process route: mixed iron or iron bag fuel tank → converter → deoxidation alloying (according to the composition) → Blowing argon station → slab coils → slab heating → Rolled rolled head tail → medium rolling head → Pre-precision rolling → Fabric rolling unit rolling → water cooling → set roll → bundle, logo, weigh, inspection → unloading roll → in the library.

[0046] When the converter is 1.2min, the white gray is 2.3kg / t, the desulfurizer is 4.8kg / t, wherein the desulfurizer comprises the following components: CAO: 55%, SiO 2 : 4%, Al 2 O 3 : 25%, Al: 14%, CAF 2 :2%.

[0047] When the converter is turned on, the steel packet is opened, and the control flow is 350-400 L / min, and the argon is blown for 10 min. Among them, the steel time is controlled for 5 min.

[0048] The deoxygenation is composed of the target, and the titanium iron alloy is adde...

Embodiment 3

[0052] Composition: C: 0.06%, Si: 0.06%, Mn: 0.50%, P: 0.024%, S: 0.015%, ALS: 0.015%, Ti: 0.030%, the margin is Fe.

[0053] Process route: mixed iron or iron bag flex → converter → deoxidation alloy → blow argon station → slab coating machine → slab heating → thick rolling head tail → medium rolling head → Pre-precision rolling → finishing mill Rolling → water cooling → Set roll → bundle, logo, weigh, inspection → unloading roll → in the library.

[0054] When the converter is fired for 1 min, the white ash is 2.5kg / t, the desulfurizer is 5.5kg / t, wherein the desulfurizer comprises the following components: CAO: 60%, SiO 2 : 3%, Al 2 O 3 : 21%, Al: 15%, CAF 2 :1%.

[0055] When the converter is turned out, the steel packet is opened and the bottom is blown, and the flow rate is controlled at 400-450 l / min, and the argon is blown for 8 min. Among them, the steel time is controlled for 4 minutes.

[0056] The deoxygenation is composed of the target, and the titanium iron all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com