Amorphous transition metal hydroxide electrode material and preparation method thereof

A technology of transition metals and hydroxides, applied in electrolytic inorganic material coatings, hybrid capacitor electrodes, etc., can solve the problem of low electrode loading, achieve high loading, good rate performance and cycle performance, good rate performance and cycle performance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

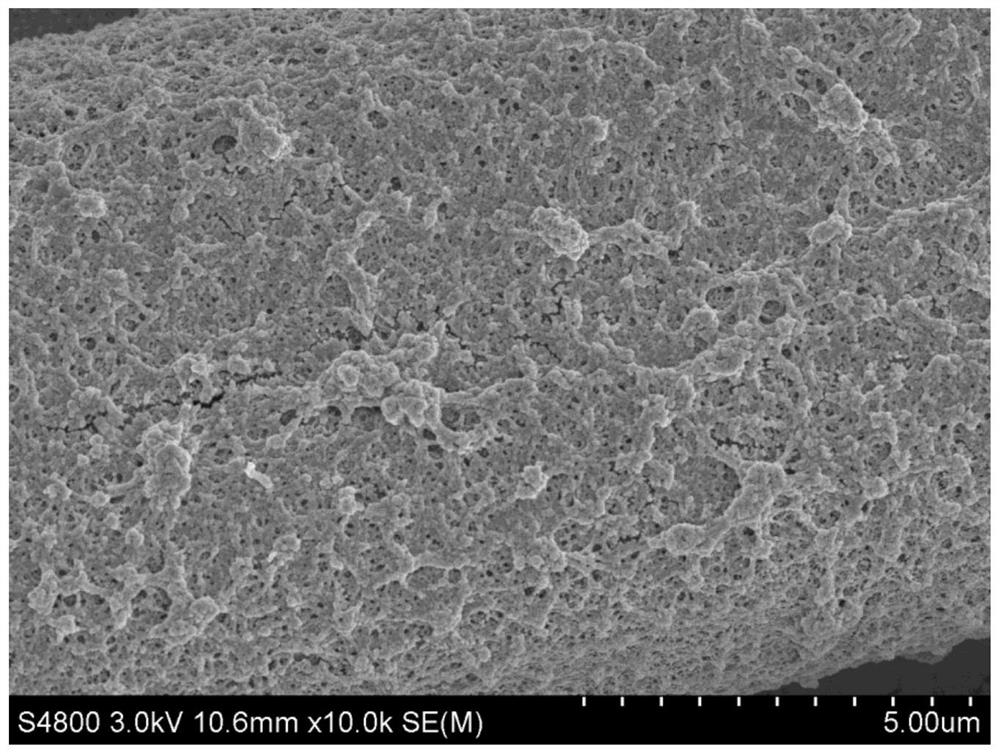

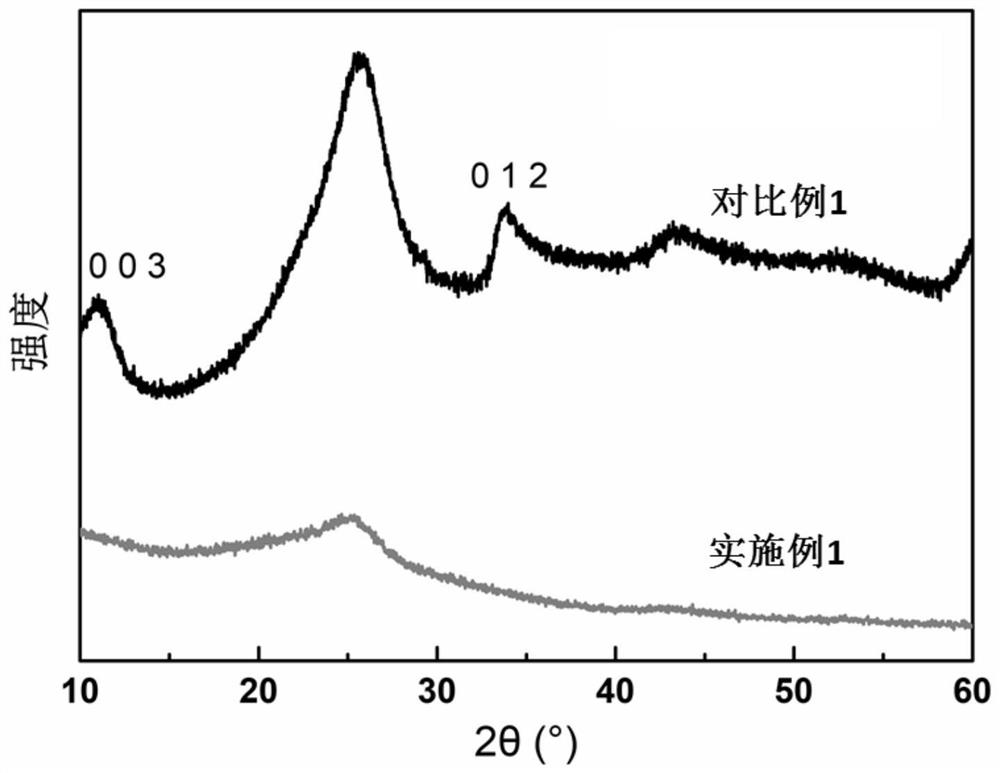

[0035] In 100mL deionized water, add 1.16g Ni(NO 3 ) 2 , 0.58g Co(NO 3 ) 2 , 0.3g of sodium alginate was stirred and dissolved to obtain an electrolyte, and the carbon cloth was used as a working electrode, immersed in the electrolyte, and deposited at a voltage of –1.0V for 900s. After the end, the working electrode was taken out and washed several times with deionized water to obtain the NiCo double metal hydroxide@carbon cloth electrode material with an active material loading of 3.8 mg cm -2 .

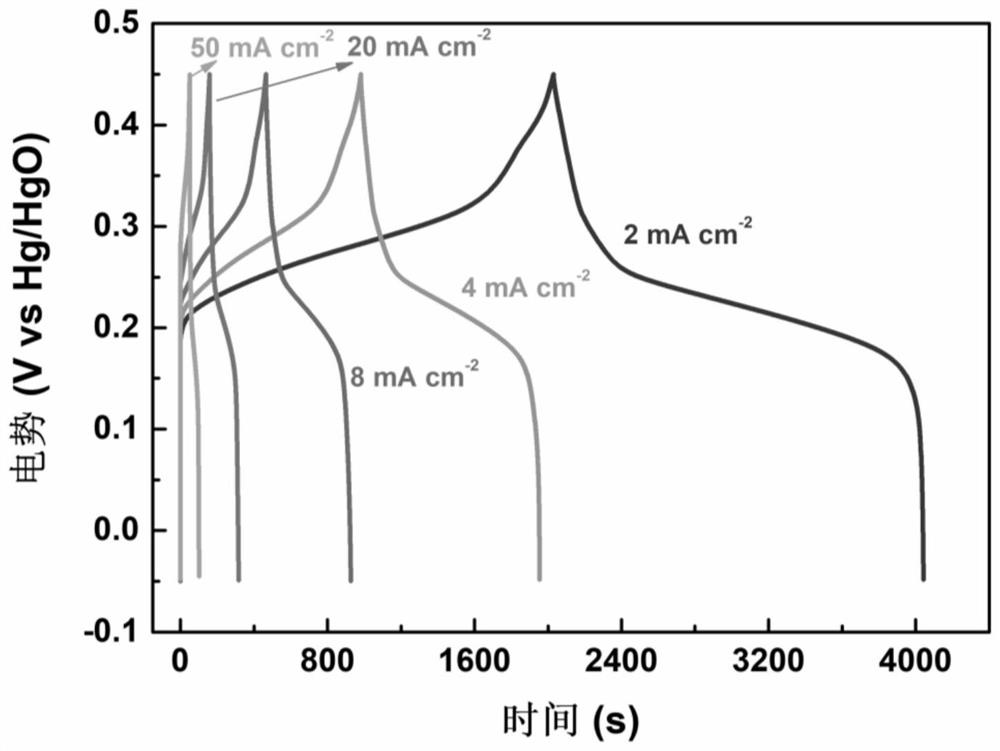

[0036] The constant current charge and discharge curves of the NiCo double metal hydroxide @ carbon cloth electrode material prepared in this example at different current densities are as follows figure 1 As shown, observing the curve, it can be found that there are obvious platforms in the charging and discharging curves of the electrode material, reflecting the energy storage mechanism of the metal hydroxide battery type capacitor, that is, Co 2+ 、Ni 2+ reversible redox rea...

Embodiment 2

[0040] In 100mL deionized water, add 2.32g Co(NO 3 ) 2 , 1.22g V(NO 3 ) 3 , 0.5g of sodium alginate was stirred and dissolved to obtain an electrolyte solution, nickel foam was used as a working electrode, immersed in the electrolyte solution, and deposited at a voltage of –1.1V for 1200s. After the end, the working electrode was taken out and washed several times with deionized water to obtain the CoV double metal hydroxide@foamed nickel electrode material with an active material loading of 5.1 mg cm -2 .

[0041] The CoV double metal hydroxide@ foamed nickel electrode material prepared in this example is at 2mA cm -2 The mass specific capacitance is as high as 2234F g -1 , the area specific capacitance is as high as 11.4F cm -2 ; when the current density increases to 50mA cm -2 , the area specific capacitance is still as high as 5.7F cm -2 (50% retention rate); after 5000 cycles of charging and discharging, the specific capacitance retention rate is 55%.

[0042] In...

Embodiment 3

[0045] In 100mL deionized water, add 1.89g Ni(Cl) 2 , 1.54g Co(Cl) 2 , 1.0g of polyethylene oxide was stirred and dissolved to obtain an electrolyte, and the carbon cloth was used as a working electrode, immersed in the electrolyte, and deposited at a voltage of –0.9V for 600s. After the end, the working electrode was taken out and washed several times with deionized water to obtain the NiCo double metal hydroxide@carbon cloth electrode material with an active material loading of 2.2 mg cm -2 .

[0046] The NiCo double metal hydroxide@carbon cloth electrode material prepared in this example is at 2mA cm -2 The mass specific capacitance is as high as 2126F g -1 , the area specific capacitance is as high as 4.7F cm -2 ; when the current density increases to 50mA cm -2 , the area specific capacitance is 1.9F cm -2 (40% retention rate); after 5000 cycles of charging and discharging, the specific capacitance retention rate is 51%.

[0047] In the NiCo double metal hydroxide@...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com