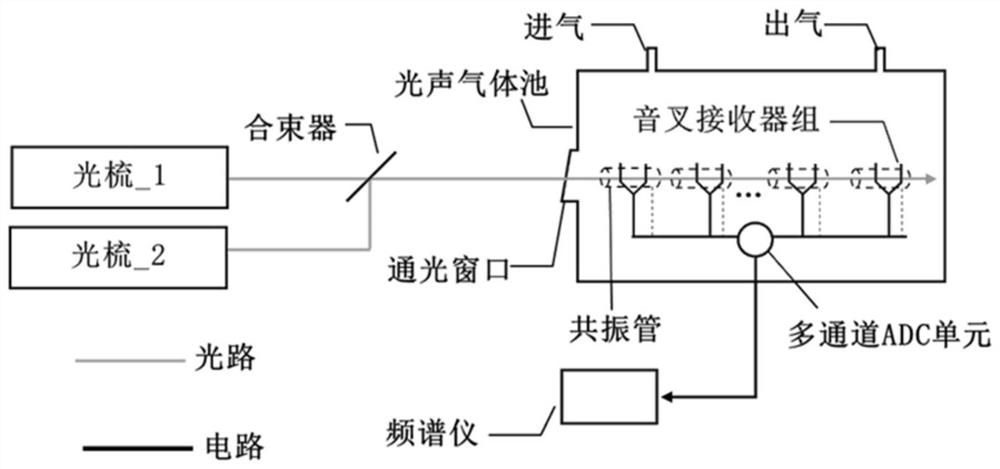

Tuning fork resonance enhanced double-optical comb multi-component gas detection system

A gas detection system and dual optical comb technology are applied in the direction of material analysis, measuring devices, and analysis materials through optical means, which can solve the problems of difficult detection, affecting measurement results, and low resolution, so as to increase detection sensitivity and solve Cross-sensitive, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

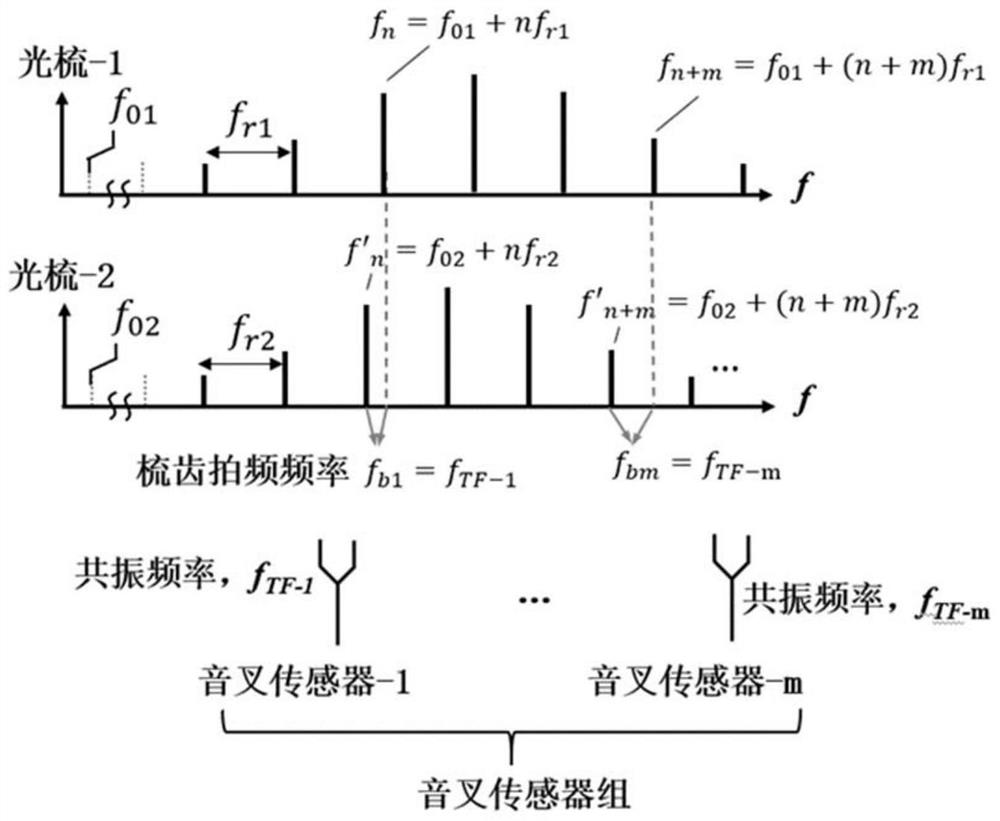

Method used

Image

Examples

Embodiment 1

[0059] Example 1: To target acetylene (C 2 h 2 ) measurement of the absorption peak group of gas molecules around 1.531 μm as an example.

[0060] Such as Figure 4 As shown, two optical comb light sources with a center wavelength around 1.531 μm are used. One of them passes through a polarization controller to adjust the polarization state. The two optical combs overlap in space after passing through the 50:50 beam combiner 4. The repetition frequency of the two optical combs (i.e. the tooth spacing) f r1 = 1GHz, f r2 =1GHz+10Hz, carrier envelope phase zero frequency f 0 , are all set to 0 (usually achieved by adjusting the pumping power of the optical comb).

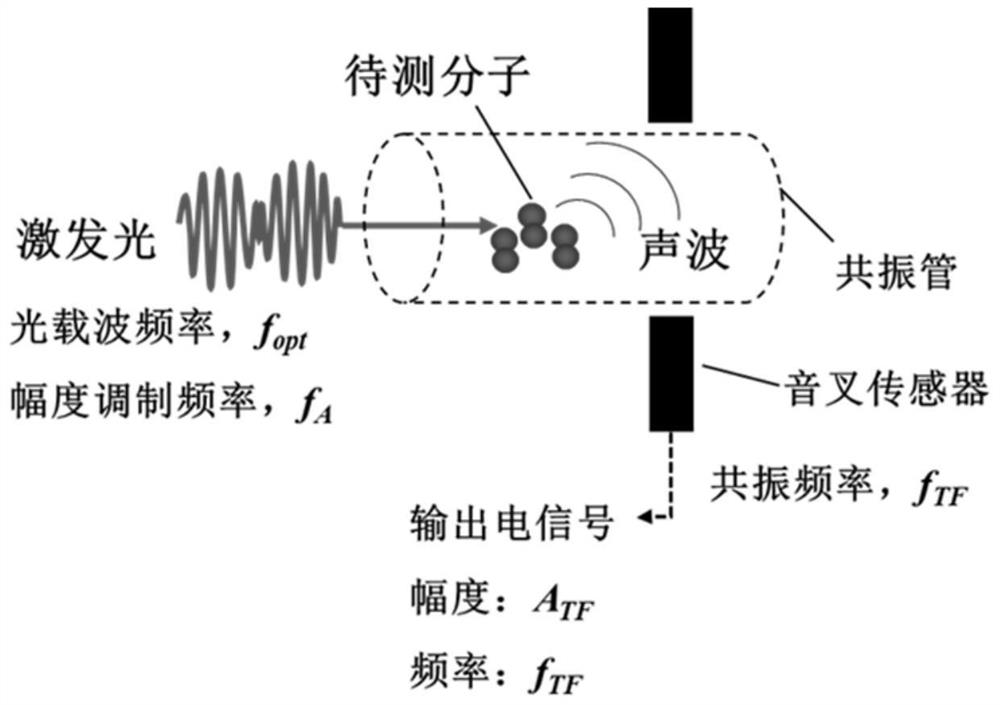

[0061] After the double-comb beam passes through the half-wave plate 5, it enters the C 2 h 2 Enhanced gas sample cell 6 for gases. The light beam enters the lens 7 with numerical aperture of NA=0.19 and the lens 8 with NA=0.38, and the photoacoustic signal induced by the optical comb is received by the tunin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com