Low-cost stable wafer-level metal diffusion bonding method and semiconductor wafer

A metal diffusion, low-cost technology, applied in the field of electronic science, can solve the problems of Cu or Al fracture, affect the bonding efficiency, easy to form oxide layer, etc., achieve the effect of reducing usage, good bonding effect, and promoting diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In this embodiment, two Si chips are bonded, which can be used for experimental verification before formal chip bonding.

[0072] A low-cost and stable wafer-level metal diffusion bonding method, comprising the following steps:

[0073] Step 1: Substrate acquisition and cleaning

[0074] Organic cleaning: First place two four-inch Si wafers in acetone solution for ultrasonic cleaning for 10 minutes, then ultrasonically clean them in isopropanol solution for 10 minutes, then put them in ultrapure water for ultrasonic cleaning for 5 minutes, and rinse with ultrapure water repeatedly to remove residues Acetone and isopropanol solutions, finally blown dry with nitrogen to remove surface organics;

[0075] Inorganic cleaning: Put two four-inch Si wafers in HF:H 2 Soak in O=1:10 solution for 1min to remove surface oxides;

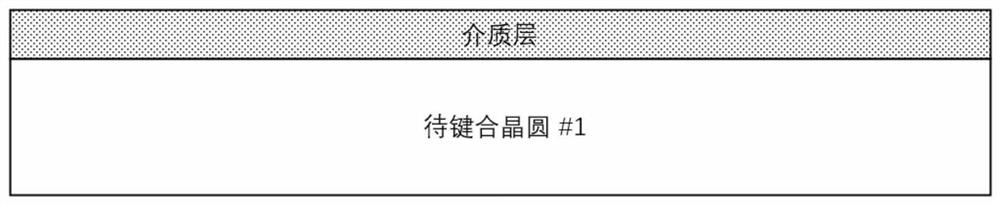

[0076] Step 2: Dielectric Layer Deposition

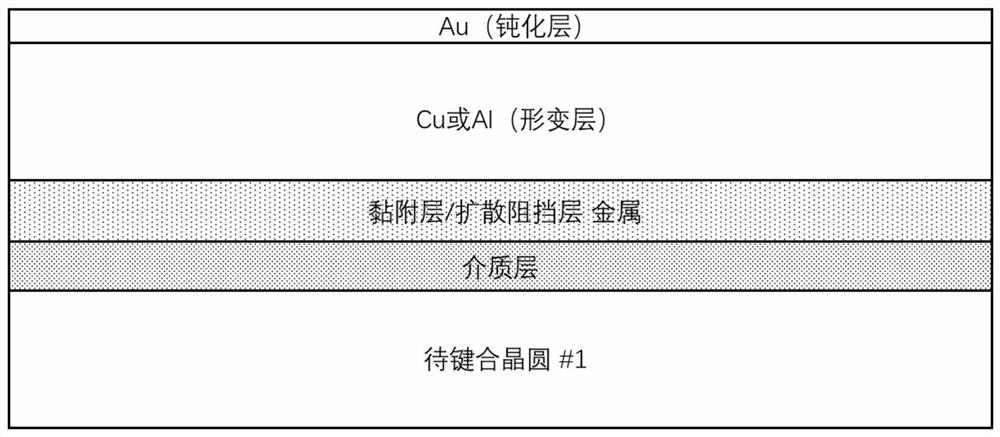

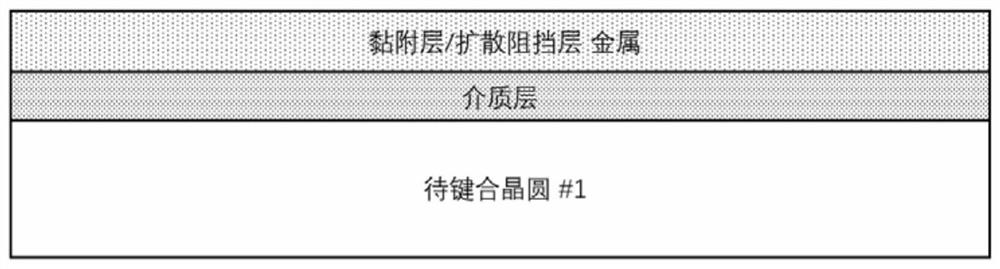

[0077] Deposit 500nm SiN on cleaned Si wafer in PECVD system x A dielectric layer to prevent the diffusi...

Embodiment 2

[0085] This embodiment can be used in the preparation of vertical GaN-based LEDs.

[0086] A method for preparing a vertical GaN-based LED, comprising the steps of:

[0087] Step 1: Wafer Acquisition and Cleaning

[0088] Organic cleaning: first place the GaN-based LED and Si chip with ohmic contact on the sapphire substrate in an acetone solution for 10 minutes of ultrasonic cleaning, then in an isopropanol solution for 10 minutes, and then put it into ultrapure water for 5 minutes of ultrasonic cleaning , rinse with ultrapure water repeatedly to remove residual acetone and isopropanol solutions, and finally dry with nitrogen to remove surface organic matter;

[0089] Step 2: Deposit metal adhesion layer, diffusion barrier layer, deformation layer and passivation layer in sequence

[0090] Using magnetron sputtering technology, the GaN-based LED and the Si wafer are sequentially sputtered to form a Ti metal adhesion layer / TiW diffusion barrier layer / Al deformation layer / Au ...

Embodiment 3

[0096] A method for preparing N-polar GaN based on a substrate lift-off method, comprising the steps of:

[0097] Step 1: Wafer Acquisition and Cleaning

[0098] Organic cleaning: first place Ga-polar GaN epitaxial wafers and Si wafers based on Si substrates in acetone solution for 10 minutes, then ultrasonically clean them in isopropanol solution for 10 minutes, then put them into ultrapure water for 5 minutes, and use them repeatedly Rinse with ultrapure water to remove residual acetone and isopropanol solutions, and finally blow dry with nitrogen to remove surface organic matter;

[0099] Inorganic cleaning: soak Ga-polar GaN epitaxial wafers based on Si substrates in HCl:H 2 O 1:5 solution for 2min to remove surface oxides; place Si sheet in HF:H 2 Soak in O=1:10 solution for 1min to remove surface oxides;

[0100] Step 2: Dielectric Layer Deposition

[0101] In the PECVD system, 400nm SiO was deposited on the cleaned Ga-polar GaN epitaxial wafer and Si wafer. 2 Diele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com