Gunn diode oscillation signal source based on dielectric integrated waveguide resonant cavity, and working method thereof

A dielectric integrated waveguide and Gunn diode technology, applied in the direction of resonators, waveguide devices, electrical components, etc., can solve the problems of large packaging volume, inability to integrate, and demanding working environment, achieve high operating frequency, and avoid waste of resources , compact and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

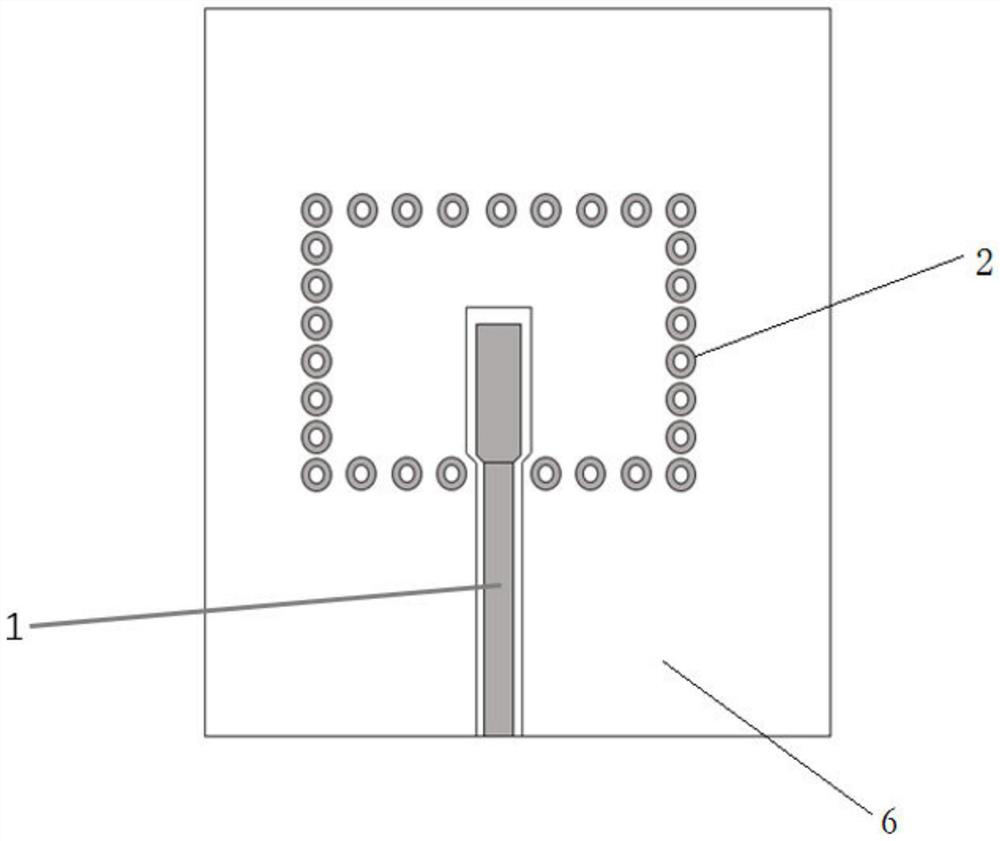

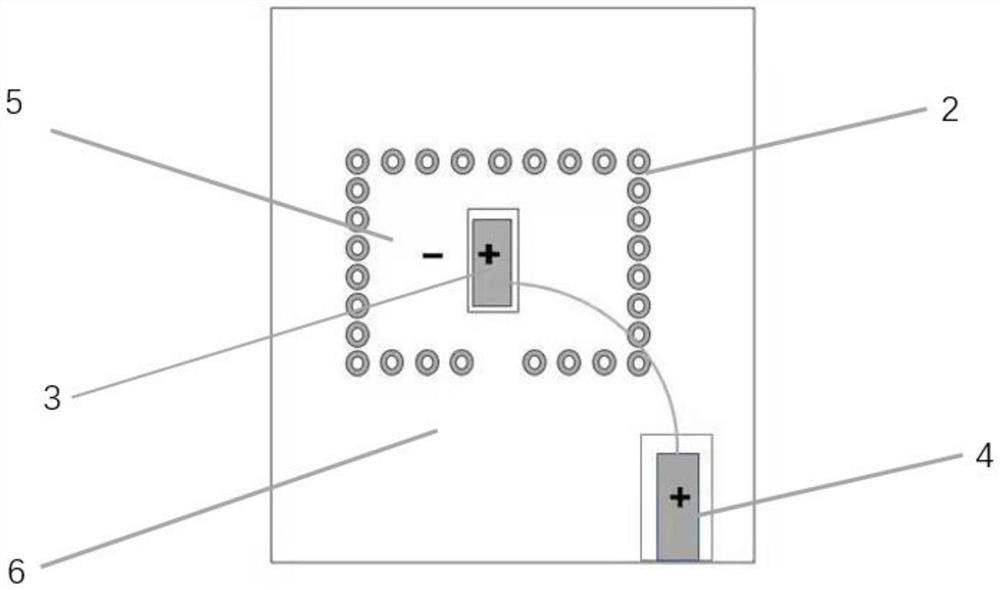

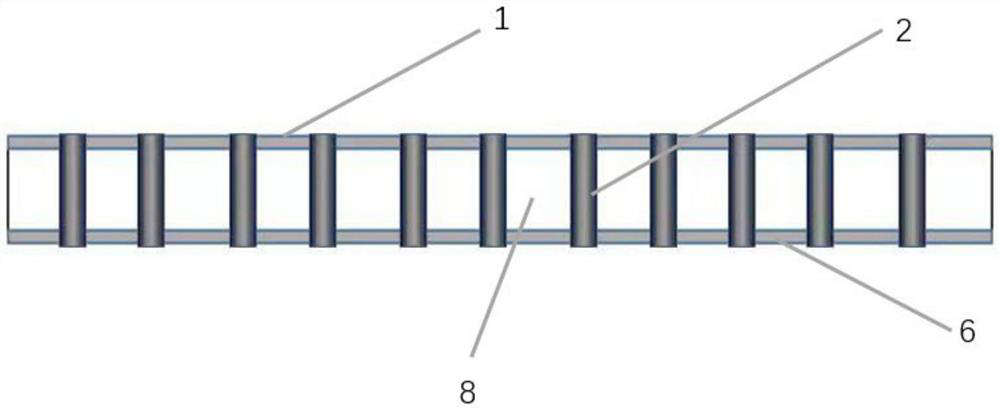

[0055] A Gunn diode oscillating signal source based on a dielectric integrated waveguide resonator, such as figure 1 , image 3 shown, including:

[0056] Top layer 1, middle layer 8 and bottom layer 6 from top to bottom; top layer 1 is a cpw (coplanar waveguide) multilayer metal structure, the middle layer 8 is an insulating sheet structure, and bottom layer 6 is a cpw (coplanar waveguide) multilayer metal structure ;

[0057] The via structure 2 that penetrates the top layer 1 , the middle layer 8 and the bottom layer 6 .

Embodiment 2

[0059] A Gunn diode oscillating signal source based on a dielectric-integrated waveguide resonator according to Embodiment 1, the difference is that:

[0060] CPW multi-layer metal structure and includes top-down 4-6um metal Au layer, 8-14um metal Ti layer, 8-12um metal Cu layer. The metal Au layer is to prevent oxidation and corrosion of the metal Cu layer, which affects the structural performance, and the metal Ti layer is to increase the adhesion of the Au layer and prevent falling off.

[0061] The middle layer 8 adopts Rogers sheet Rogers-4350B with a thickness of 4mil. It provides low dielectric constant and low loss, and its price is a fraction of traditional microwave materials, which saves production costs and improves the Q factor of the resonant cavity, but the selection of materials is not limited to this.

[0062] The via structure 2 is a structure that penetrates the top layer 1 , the middle layer 8 and the bottom layer 6 from top to bottom, and the via structur...

Embodiment 3

[0064] A Gunn diode oscillating signal source based on a dielectric-integrated waveguide resonator according to Embodiment 2, the difference is that:

[0065] The thickness of the metal Au layer is 5um, the thickness of the metal Ti layer is 12um, and the thickness of the metal Cu layer is 10um.

[0066] The diameter of the cylindrical hole is 100um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com