Orthopedic implant device

An orthopedic implant and tension technology, applied in the field of medical devices, can solve the problems of intramedullary nail damage, small contact area, and large activity space, so as to avoid fragmentation and collapse, increase the force area, and reduce the impact The effect of force strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

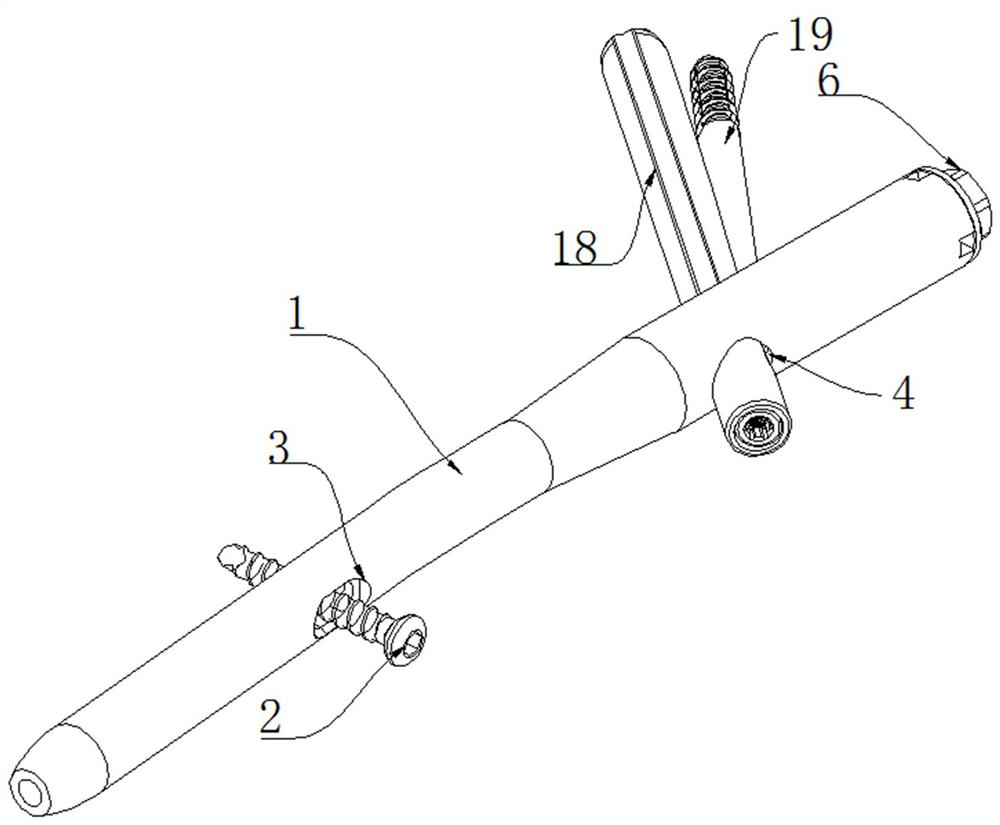

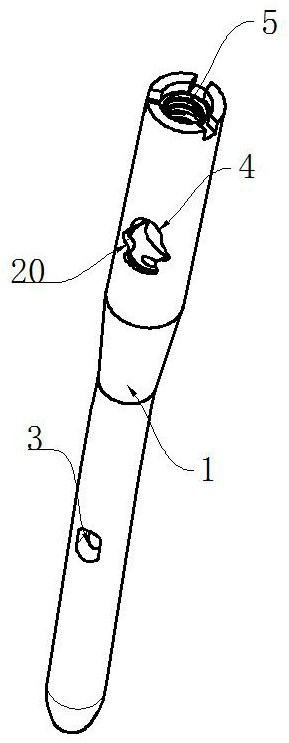

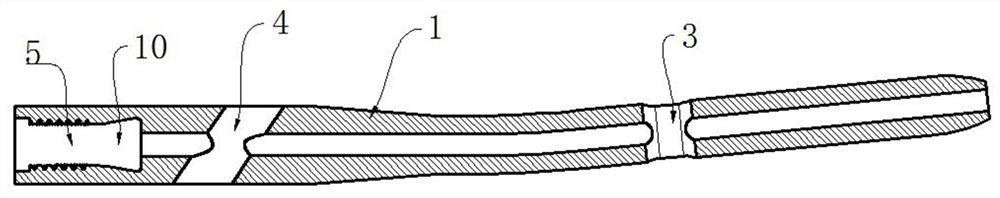

[0044] Such as Figure 1-16 As shown, this embodiment discloses an orthopedic implant device, including an intramedullary nail unit, which includes an intramedullary nail main body 1, a fixing unit 2, and a tension fixing unit, and the intramedullary nail main body 1 is made of a continuous fiber composite material , the intramedullary nail main body 1 includes a main body core 27 and a main body shell 28, wherein the main body core 27 is made of multi-layer laid-up molded continuous fiber composite material. The specific preparation steps of the intramedullary nail main body 1 are as follows:

[0045] Step 1 (core forming): Lay the continuous fiber composite material in multiple layers, and then put it into the mold and mold it together with the steel core to form a core structure; it is also optional to form two halves first, and then embed the steel core and mold them together to form a whole ; Pressure 1-4MPa, preferably 2Mpa, temperature 370-410°C, preferably 400°C, hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com