Method for producing inositol and co-producing monopotassium phosphate by adopting corn steep liquor as well as inositol and monopotassium phosphate produced by the method

A technology of potassium dihydrogen phosphate and corn steep liquor, which is applied in the field of inositol and inositol production, can solve the problems of serious scaling of evaporators, difficult purification of impurities, and high labor intensity of workers, and is suitable for large-scale popularization, application and production. Unique and novel process, unique and novel effect of process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

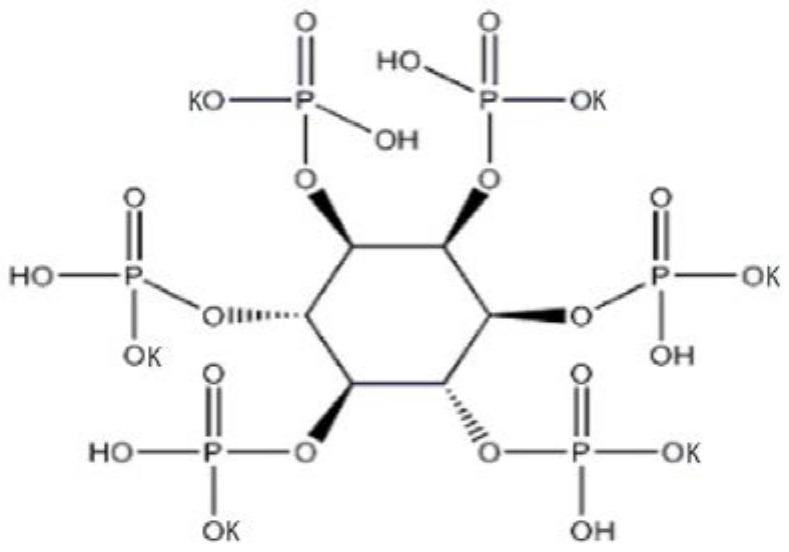

[0057] Use special anion exchange resin acrylic acid anion exchange resin (Ningbo Zhengguang Resin Co., Ltd., 25kg per bag) to selectively adsorb phytic acid in corn steep liquor. Several adsorption towers are arranged in parallel. According to the experimental data, when the resin adsorption per unit volume reaches a certain When the adsorption capacity of the resin is close to saturation, the material (corn steep liquor) is switched to another adsorption tower to continue the adsorption, and this adsorption tower enters the desorption and regeneration process. Rinse the resin column with purified water first, and then desorb with 10% potassium chloride solution by weight, so that the purity of the desorbed potassium phytate is greatly increased, laying the foundation for the next step of producing high-purity inositol and high value-added potassium dihydrogen phosphate. A good resin column continues to adsorb into the next cycle.

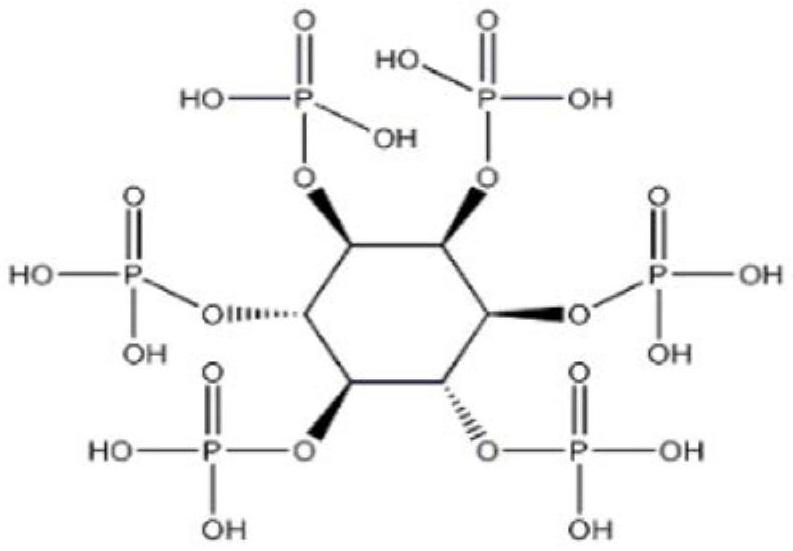

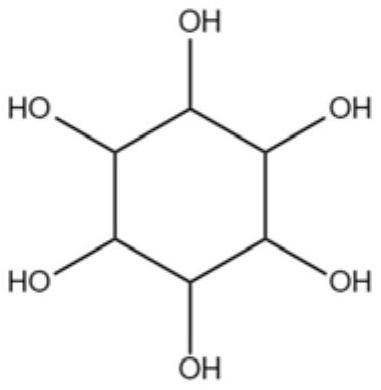

[0058] Resin adsorption principle:

[0059...

Embodiment 2

[0074] Adopt special anion exchange resin acrylic acid anion exchange resin (with embodiment 1) to carry out selective adsorption to the phytic acid in corn steep liquor (with embodiment 1), several adsorption towers are arranged in parallel, according to experimental data, when the resin adsorption of unit volume reaches A certain amount of adsorption, the resin adsorption is close to saturation, the material (corn steep liquor) is switched to another adsorption tower to continue the adsorption, and this adsorption tower enters the desorption and regeneration process. Rinse the resin column with purified water first, and then use 11% by weight of potassium chloride solution for desorption, so that the purity of the desorbed potassium phytate is greatly increased, laying the foundation for the next step of producing high-purity inositol and high value-added potassium dihydrogen phosphate, desorption A good resin column continues to adsorb into the next cycle.

[0075] The pota...

Embodiment 3

[0082] Adopt special anion exchange resin acrylic acid anion exchange resin (with embodiment 1) to carry out selective adsorption to the phytic acid in corn steep liquor (with embodiment 1), several adsorption towers are arranged in parallel, according to experimental data, when the resin adsorption of unit volume reaches When a certain amount of adsorption is reached and the resin adsorption is close to saturation, the material (corn steep liquor) is switched to another adsorption tower to continue the adsorption, and this adsorption tower enters the desorption and regeneration process. Rinse the resin column with purified water first, and then desorb with 12% potassium chloride solution by weight, so that the purity of the desorbed potassium phytate is greatly increased, laying the foundation for the next step of producing high-purity inositol and high value-added potassium dihydrogen phosphate. A good resin column continues to adsorb into the next cycle.

[0083] The conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com