Synthesis method of benzethonium chloride

A synthesis method and technology of benzethonium chloride, applied in the field of chemistry, can solve problems such as hidden dangers of large production safety, and achieve the effects of good purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

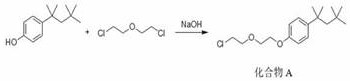

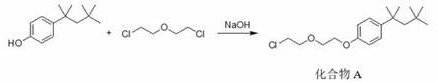

Image

Examples

preparation example Construction

[0015] A kind of synthetic method of benzethonium chloride, this synthetic method comprises the steps:

[0016] (1) According to the mass ratio of 52% sodium hydroxide solution, dichloroethyl ether, phase transfer catalyst, and octylphenol, the mass ratio is 90:80:0.6~0.8:30, and the material is taken, and the mass fraction is 52 % sodium hydroxide solution, dichloroethyl ether, phase transfer catalyst, and octylphenol are put into the reactor, stirred, heated up, and kept warm to react to obtain Compound A; the phase transfer catalyst is benzyltriethylammonium chloride;

[0017] (2) According to the mass ratio of compound A, benzyldimethylamine and water of 45:20:30~35, take the material, stir compound A, benzyldimethylamine and water evenly, protect with nitrogen, heat up, and react , cooling, that is, benzethonium chloride.

Embodiment 1

[0019] A kind of synthetic method of benzethonium chloride, this synthetic method comprises the steps:

[0020] (1) Put 900kg of sodium hydroxide solution with a mass fraction of 52% into the reaction kettle, add 800kg of dichloroethyl ether, 6kg of phase transfer catalyst, 300kg of octylphenol, start stirring, slowly raise the temperature to reflux, and keep it warm for 3 hours , TLC tracking and detection of the reaction process, until the end of the reaction, add water to the reaction kettle, wash and separate the layers, separate the organic layer, wash with water once, and recover the solvent under reduced pressure in the organic phase. After the solvent recovery is completed, change to distillation under reduced pressure to obtain 513kg of Compound A, with a purity of 97.8%;

[0021] (2) Put 450kg of compound A, 200kg of benzyldimethylamine and 300kg of water into the reactor, start stirring, replace with nitrogen, protect with nitrogen, heat up to 115°C, continue to rea...

Embodiment 2

[0024] A kind of synthetic method of benzethonium chloride, this synthetic method comprises the steps:

[0025] (1) Put 900kg of sodium hydroxide solution with a mass fraction of 52% into the reactor, add 800kg of dichloroethyl ether, 7kg of phase transfer catalyst, 300kg of octylphenol, start stirring, slowly raise the temperature to reflux, and keep it warm for 3 hours , TLC tracking and detection of the reaction process, until the end of the reaction, add water to the reaction kettle, wash and separate the layers, separate the organic layer, wash with water once, and recover the solvent under reduced pressure in the organic phase. After the solvent recovery is completed, change to distillation under reduced pressure to obtain 546kg compound A, purity 98.8%;

[0026] (2) Put 450kg of compound A, 200kg of benzyldimethylamine and 330kg of water into the reactor, start stirring, replace with nitrogen, protect with nitrogen, heat up to 115°C, continue to react for 7h, cool down,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com