Synthesis method of 3-methyl-2-butyl mercaptan

A synthesis method and technology of butanethiol, applied in the field of flavors and fragrances, can solve the problems of low extraction rate, oxidation side reactions, etc., and achieve the effects of reducing reaction temperature, improving yield and optimizing reaction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

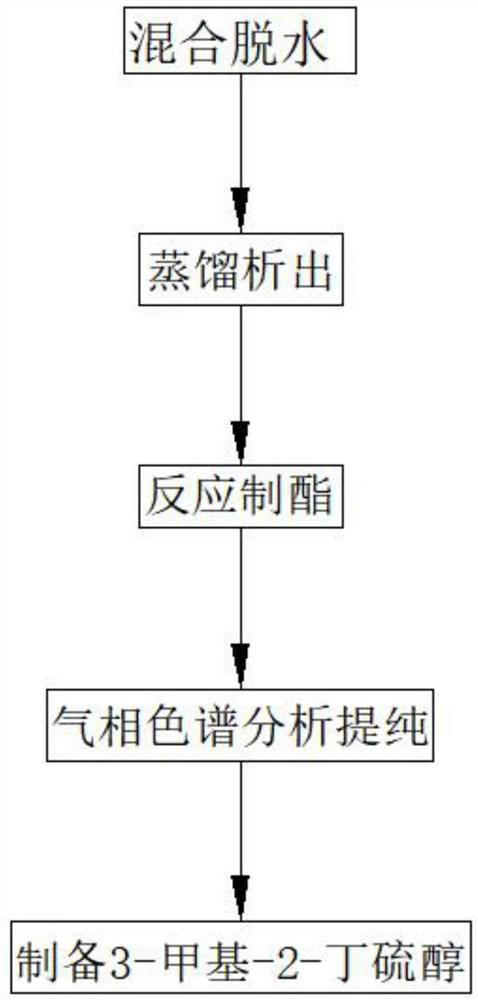

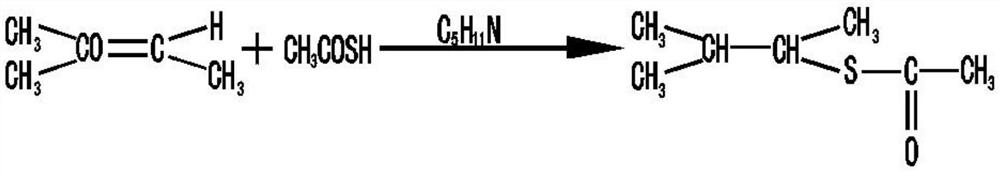

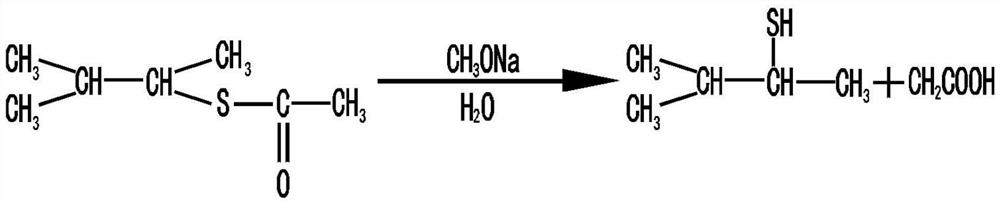

Method used

Image

Examples

Embodiment 1

[0021] A kind of synthetic method of 3-methyl-2-butanethiol, its synthetic steps are as follows:

[0022] S1: Take 10 parts of tert-amyl alcohol and 1 part of concentrated sulfuric acid in parts by weight, first add tert-amyl alcohol into the volumetric flask, then slowly add concentrated sulfuric acid, stir and mix for 1 hour, and heat to 70 degrees, and continue to heat to 80 degrees , a dehydration reaction occurs, during which the liquid is distilled until the distilled liquid stops;

[0023] In the distilled liquid, add the sodium bicarbonate solution that is 0.7 parts by weight, stir for 5 minutes, let stand for 1 hour to separate layers, and the main components of the product are trimethylethylene, isomers and a small amount of tert-amyl alcohol at this time ;

[0024] S2: Use a 1.2m-long rectification column and a glass spring packing to rectify the distilled liquid obtained from S1, and collect the fraction at 30 degrees. In this temperature range, the isomers begin ...

Embodiment 2

[0033] A kind of synthetic method of 3-methyl-2-butanethiol, its synthetic steps are as follows:

[0034] S1: Take 8 parts of tert-amyl alcohol and 1 part of concentrated sulfuric acid by weight, first add tert-amyl alcohol into the volumetric flask, then slowly add concentrated sulfuric acid, stir for 1.5 hours, heat to 75 degrees, and continue to heat to 85 degrees, Dehydration reactions, in which liquid is distilled off until the distilling of liquid ceases;

[0035] In the distilled liquid, add the sodium bicarbonate solution that is 0.5 parts by weight, stir for 15 minutes, and let stand for 2.5 hours to separate layers. At this time, the main components of the product are trimethylethylene, isomers and a small amount of tert-amyl alcohol ;

[0036] S2: Use a 1.2m-long rectification column and a glass spring packing to rectify the distilled liquid obtained from S1, and collect the fraction at 35 degrees. Under this temperature range, the isomers begin to evaporate and di...

Embodiment 3

[0045] A kind of synthetic method of 3-methyl-2-butanethiol, its synthetic steps are as follows:

[0046] S1: Take 12 parts of tert-amyl alcohol and 1.5 parts of concentrated sulfuric acid by weight, first add tert-amyl alcohol into the volumetric flask, then slowly add concentrated sulfuric acid, stir for 2 hours, heat to 80 degrees, and continue to heat to 85 degrees, A dehydration reaction in which liquid is distilled off; until the distilling of liquid ceases;

[0047] In the distilled liquid, add the sodium bicarbonate solution that is 0.8 part by weight, stir for 10 minutes, leave standstill for 1.5 hours to separate layers, the main components of the product are trimethylethylene, isomers and a small amount of tert-amyl alcohol at this time ;

[0048]S2: Use a 1.2m-long rectification column and a glass spring packing to rectify the distilled liquid obtained from S1, and collect the fraction at 33 degrees. In this temperature range, the isomers begin to evaporate and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com