Demulsifier for oil-water transition layer rich in polymers and colloid asphaltene in crude oil dehydration system and preparation method of oil-water transition layer demulsifying agent

A crude oil dehydration and demulsifier technology, applied in the direction of chemical dehydration/demulsification, etc., can solve problems such as excessive water content of oil products, disorder of dehydration system, environmental pollution, etc., and achieve safe use, flexibility and good wettability. , the effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

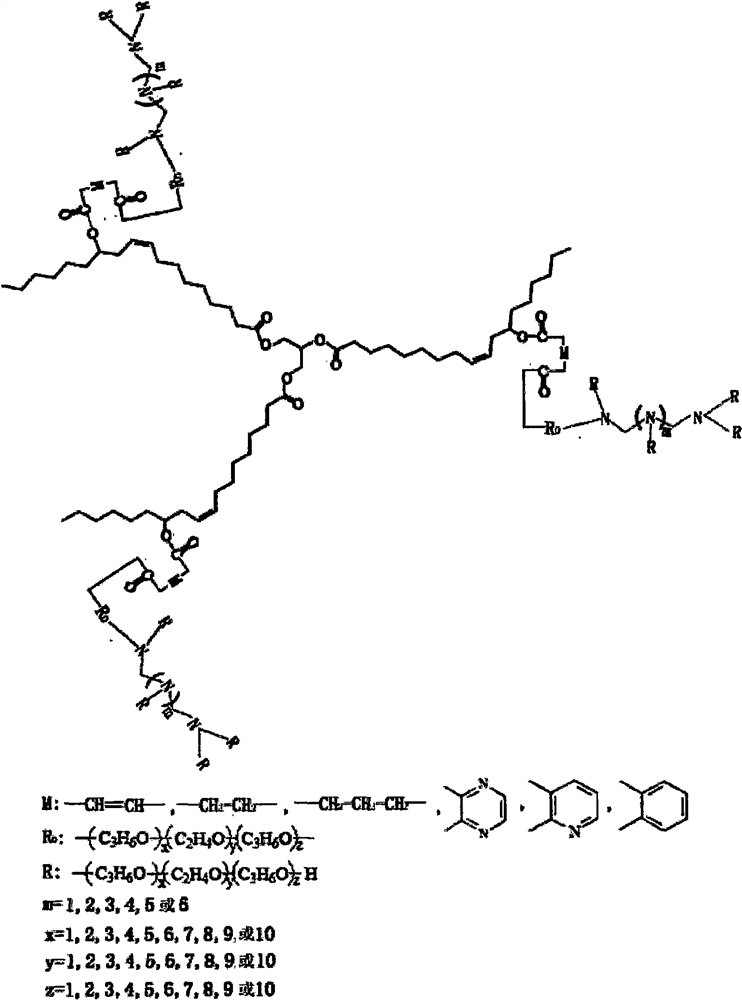

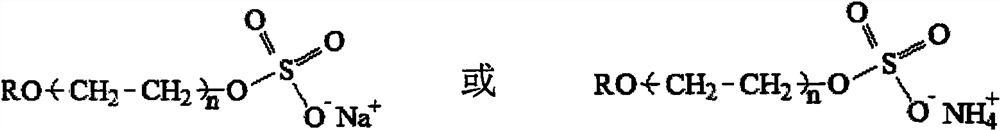

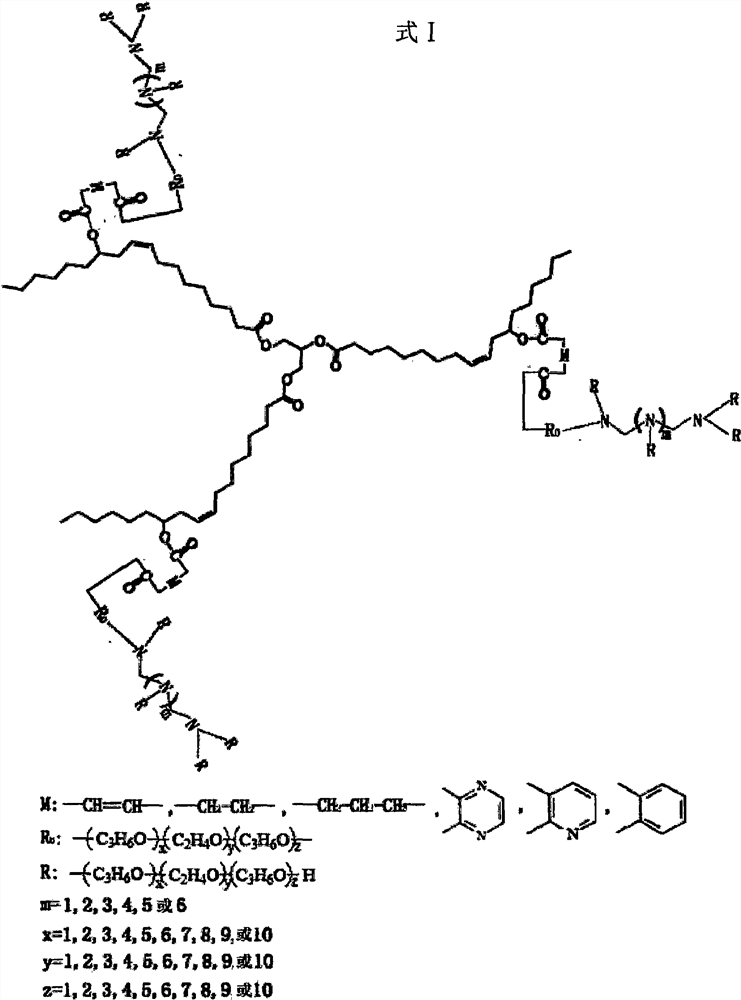

Method used

Image

Examples

Embodiment approach 1

[0043] 1. Preparation of Oil Head YPAE1

[0044]According to the mass ratio, tetraethylenepentamine: propylene oxide = 1: 199, first put a specified amount of tetraethylenepentamine into the reactor, heat up to 88-90°C, use nitrogen to bubble from the bottom of the reactor for 1 hour and measure Water content, and then measure the water content every half an hour until the water content is less than 0.03%, vacuumize, when the pressure in the reactor is -0.09~-0.08MPa, first introduce tetraethylene five-thirds of the mass of epoxy Propane, then raise the temperature to 99~105℃, keep the reaction pressure at 0.4~0.5MPa, when the pressure drops to 0.02MPa, then feed the remaining amount of propylene oxide, the reaction pressure is 0.4~0.5MPa, and the reaction temperature is 125~ 135°C, when the pressure drops to 0.02MPa, keep it warm for half an hour, and then cool down to 80°C to get YPAE1 oil head.

[0045] 2. Preparation of Demulsifier DPAE1

[0046] According to the mass ra...

Embodiment approach 2

[0059] 1. Preparation of Oil Head YPAE2

[0060] According to the mass ratio, mannitol: propylene oxide=1: 299, first put the prescribed amount of mannitol into the reactor, heat up to 88-90°C, use nitrogen to bubble from the bottom of the reactor for 1 hour and measure the water content, and then Bubble for half an hour to measure the water content, until the water content is less than 0.03%, vacuumize, when the pressure in the reactor is -0.09~-0.08MPa, first pass propylene oxide with one-third of the mass of mannitol, and then heat up to 99 ~ 105°C, keep the reaction pressure at 0.4 ~ 0.5MPa, when the pressure drops to 0.02MPa, then feed the remaining amount of propylene oxide, the reaction pressure is 0.4 ~ 0.5MPa, the reaction temperature is 125 ~ 135°C, when the pressure drops When it reaches 0.02MPa, keep it warm for half an hour, then cool down to 80°C to get YPAE2 oil head.

[0061] 2. Preparation of demulsifier DPAE2

[0062] According to the mass ratio, YPAE2: eth...

Embodiment approach 3

[0075] 1. Preparation of oil head YPAE3

[0076] According to the mass ratio, ethyl hydrogen-containing silicone oil: propylene oxide = 1:399, first put a specified amount of ethyl hydrogen-containing silicone oil into the reactor, raise the temperature to 88-90°C, and bubble nitrogen from the bottom of the reactor for 1 hour And measure the water content, and then measure the water content every half an hour until the water content is less than 0.03%, vacuumize, when the pressure in the reactor is -0.09~-0.08MPa, first pass one-third of the mass of ethyl hydrogen-containing silicone oil One propylene oxide, then heat up to 99-105°C, keep the reaction pressure at 0.4-0.5MPa, when the pressure drops to 0.02MPa, then feed the remaining amount of propylene oxide, the pressure should be 0.4-0.5MPa, the reaction The temperature is 125-135°C. When the pressure drops to 0.02MPa, keep the heat for half an hour, and then lower the temperature to 80°C to obtain the YPAE3 oil head.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com