Back contact heterojunction solar cell capable of improving insulation isolation effect and manufacturing method thereof

A solar cell, insulation and isolation technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficulty in ensuring the stability of the production process, strict alignment requirements, and inapplicability to large-scale mass production, so as to reduce performance damage The complexity of the alignment, increase the fill factor, and avoid the effects of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

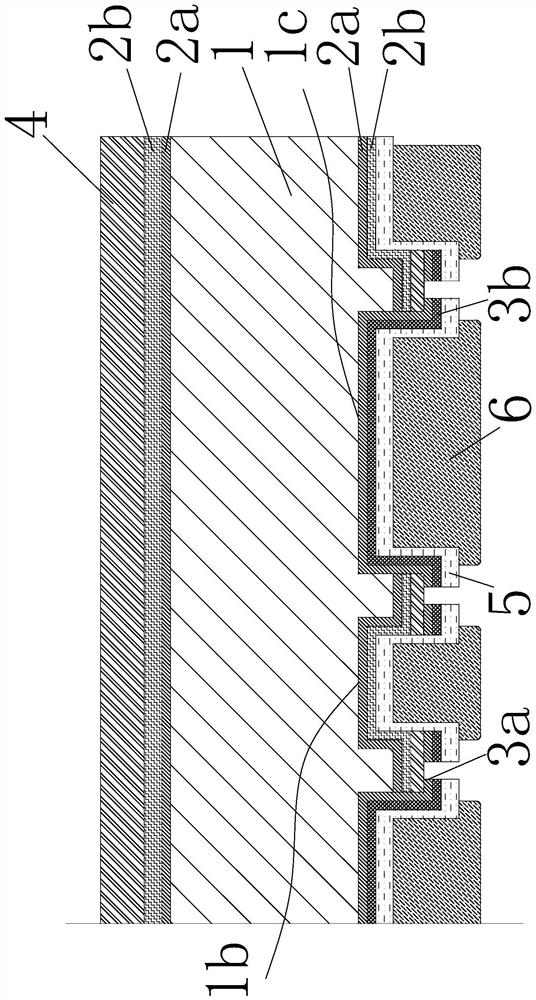

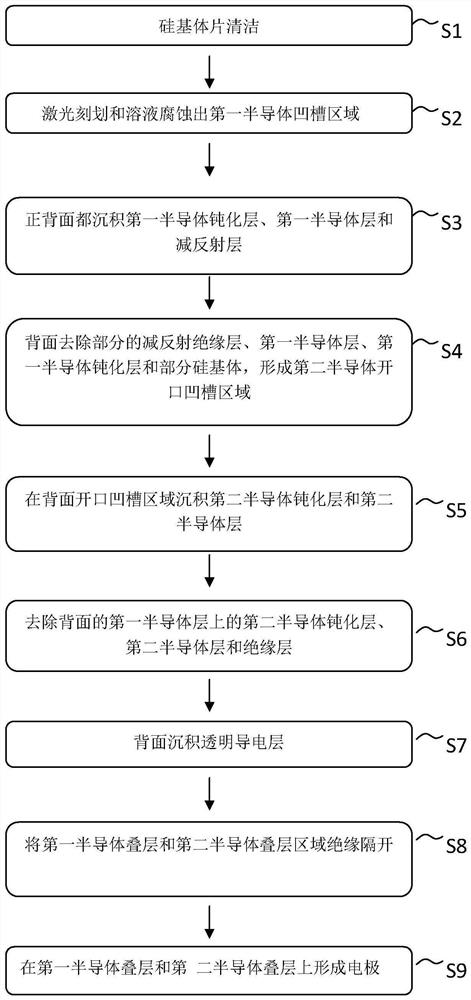

[0024] A back contact heterojunction solar cell with improved insulation and isolation effect, which comprises a semiconductor substrate whose first main surface is divided into a first conduction region of the first conductivity type and a second conduction region of the second conduction type, etching the first conduction The groove in the first conductive region formed by the semiconductor substrate in the inner region of the region and the groove in the second conductive region formed by etching the semiconductor substrate in the second conductive region; the boundary region between the first conductive region and the second conductive region is not formed by etching Convex.

[0025] The semiconductor substrate is a single crystal silicon wafer, a cast single crystal silicon wafer or a polycrystalline silicon wafer.

[0026] The second main surface of the semiconductor substrate is sequentially provided with a third conductivity type film layer and an anti-reflection film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com