Lithium ion battery electrolyte and preparation method thereof

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of low capacity retention rate, low-temperature charging lithium evolution, poor low-temperature performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

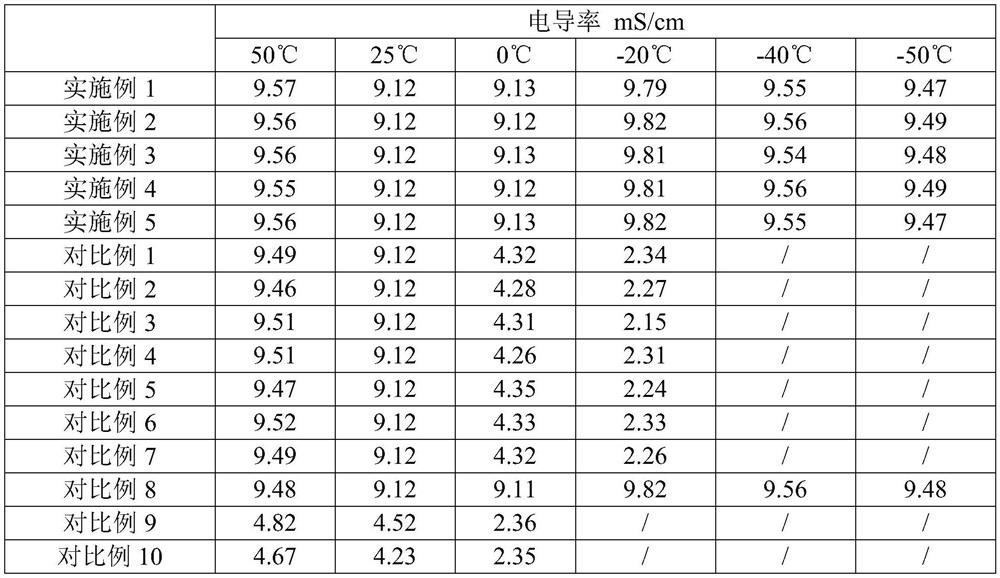

Examples

Embodiment 1

[0027] Step 1. Take dimethyl carbonate: ethyl methyl carbonate: propylene carbonate: ethylene carbonate mass ratio of 2:11:2:1 organic solvents and mix them evenly to obtain a mixed solvent, set aside; take ethyl acetate: glycerin Ester: bismorpholino diethyl ether: tris(2,2,2-trifluoroethyl) phosphate: propenyl-1,3-sultone: ethoxy pentafluorocyclotriphosphazene mass ratio Each additive is 2:3:0.2:0.5:1:1, for standby; the mass ratio of the total amount of additives to the total amount of organic solvent is 1:90;

[0028] Step 2. Stir and mix ethyl acetate and glyceride at -10°C to obtain a mixture for later use;

[0029] Step 3. Take half of the mixed solvent, add lithium tetrafluoroborate and lithium dioxalate borate at the same time, stir and mix evenly, then add the mixture in step 2, stir and mix evenly to obtain the first mixed solution;

[0030] Step 4. Take the other half of the mixed solvent, add ethoxypentafluorocyclotriphosphazene while stirring, mix well and heat ...

Embodiment 2

[0036] Step 1, take dimethyl carbonate: ethyl methyl carbonate: propylene carbonate: ethylene carbonate mass ratio of 3:7:1:2 organic solvents and mix them evenly to obtain a mixed solvent, set aside; take ethyl acetate: glycerin Ester: bismorpholino diethyl ether: tris(2,2,2-trifluoroethyl) phosphate: propenyl-1,3-sultone: ethoxy pentafluorocyclotriphosphazene mass ratio Each additive is 1:4:0.1:1:2:0.5, and it is reserved; the mass ratio of the total amount of additives to the total amount of organic solvent is 2:85;

[0037] Step 2. Stir and mix ethyl acetate and glyceride at -5°C to obtain a mixture for later use;

[0038] Step 3. Take half of the mixed solvent, add lithium tetrafluoroborate and lithium dioxalate borate at the same time, stir and mix evenly, then add the mixture in step 2, stir and mix evenly to obtain the first mixed solution;

[0039] Step 4. Take the other half of the mixed solvent, add ethoxypentafluorocyclotriphosphazene while stirring, mix well and ...

Embodiment 3

[0045] Step 1, take dimethyl carbonate: ethyl methyl carbonate: propylene carbonate: ethylene carbonate mass ratio of 4:3:2:1 of organic solvents and mix them evenly to obtain a mixed solvent, set aside; take ethyl acetate: glycerin Ester: bismorpholino diethyl ether: tris(2,2,2-trifluoroethyl) phosphate: propenyl-1,3-sultone: ethoxy pentafluorocyclotriphosphazene mass ratio Each additive is 3:2:0.3:2:1.5:1, for standby; wherein the mass ratio of the total amount of additives to the total amount of organic solvent is 4:75;

[0046] Step 2. Stir and mix ethyl acetate and glyceride at -20°C to obtain a mixture for later use;

[0047] Step 3. Take half of the mixed solvent, add lithium tetrafluoroborate and lithium dioxalate borate at the same time, stir and mix evenly, then add the mixture in step 2, stir and mix evenly to obtain the first mixed solution;

[0048] Step 4. Take the other half of the mixed solvent, add ethoxypentafluorocyclotriphosphazene while stirring, mix well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com